Monthly Archives: May 2017

Tribology of Polymers by Tribometer

Tribology of Polymers are commonly seen for tribological applications, such as tires, bearings and conveyor belts. Different wear mechanisms occur depending on the mechanical properties of the polymer, the contact conditions, and the properties of the debris or transfer film formed during the wear process. In order to ensure that the polymers possess sufficient wear resistance under the service conditions, reliable and quantifiable tribological evaluation is in need. It allows us to quantitatively compare the wear behaviors of different polymers in a controlled and monitored manner and to select the best candidate for the target application. The Nanovea Tribometer offers repeatable wear and friction testing using ISO and ASTM compliant rotative and linear modes, with optional high temperature wear and lubrication modules available in one pre-integrated system. This unmatched range allows users to simulate different work environment of the polymers including concentrated stress, wear and high temperature, etc.

Transparent Film Thickness by 3D Non Contact Profilometry

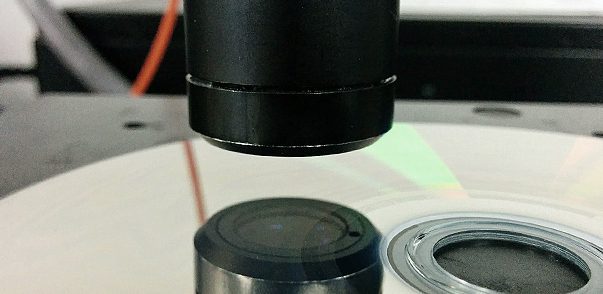

Transparent film thickness and uniformity is critical for product quality and performance. For example, in CD, DVD and Blu-Ray Disc (BO) production, precise control of the thickness and uniformity of the transparent cover and space layers plays an important role in avoiding focus errors of the laser. Improper injection molding process during CD and BO production may lead to stress-induced birefringence and unreliable data reading. An accurate thickness measurement of the transparent film ensures reliable product inspection and quality control.