Monthly Archives: February 2015

Corrosion Profilometry Is Application Of The Year

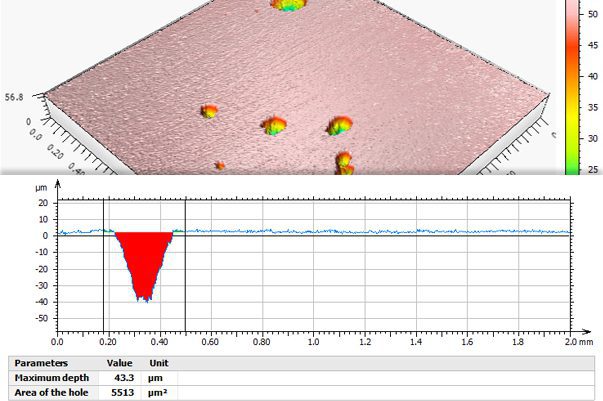

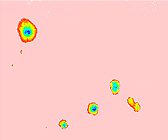

With the Nace Corrosion Conference only weeks away Nanovea highlights pitting corrosion measurement as its most popular profilometry application of 2014. The Nanovea Profilometer has quickly become the choice in the corrosion community for its accurate and reliable measurement. Primary area of interest include pitting depth, volume, area and density. Learn more in this months app note below.

Hardness Distribution of Hardened Metal Using Nanoindentation

In this application, the Nanovea Mechanical Tester in nanoindentation mode is used to measure the

hardness distribution of the hardened surface on the cross section of a surface hardened metal.

Hardness Distribution of Hardened Metal Using Nanoindentation

Corrosion Surface Analysis Using 3D Profilometry

In this application the Nanovea PS50 Profilometer is used to analyze the surface morphology of the

samples after service in corrosive environment. Surface roughness, materials loss and pits on the

sample surface are measured to provide more insight in the corrosion mechanism.

TMS 2015

The TMS Annual Meeting & Exhibition brings together more than 4,000 business leaders, engineers, scientists and other professionals in the materials field for an outstanding exchange of technical knowledge leading to solutions in the workplace and in society. Learn more

Nace CORROSION 2015

Join NACE International and fellow corrosion professionals at the world’s largest corrosion conference and expo. CORROSION 2015 will once again join more than 7,000 corrosion professionals and 450 exhibiting companies in Dallas, Texas for an educational event focused on the prevention and mitigation of corrosion worldwide. Learn more