Acabado superficial de paneles alveolares con perfilometría 3D

INTRODUCCIÓN

La rugosidad, la porosidad y la textura de la superficie del panel alveolar son factores críticos que deben cuantificarse para el diseño final del panel. Estas cualidades superficiales pueden correlacionarse directamente con las características estéticas y funcionales de la superficie del panel. Una mejor comprensión de la textura y la porosidad de la superficie puede ayudar a optimizar el procesamiento y la fabricabilidad de la superficie del panel. Se necesita una medición cuantitativa, precisa y confiable de la superficie del panel alveolar para controlar los parámetros superficiales para los requisitos de aplicación y pintura. Los sensores sin contacto Nanovea 3D utilizan una tecnología confocal cromática única capaz de medir con precisión estas superficies de los paneles.

OBJETIVO DE MEDICIÓN

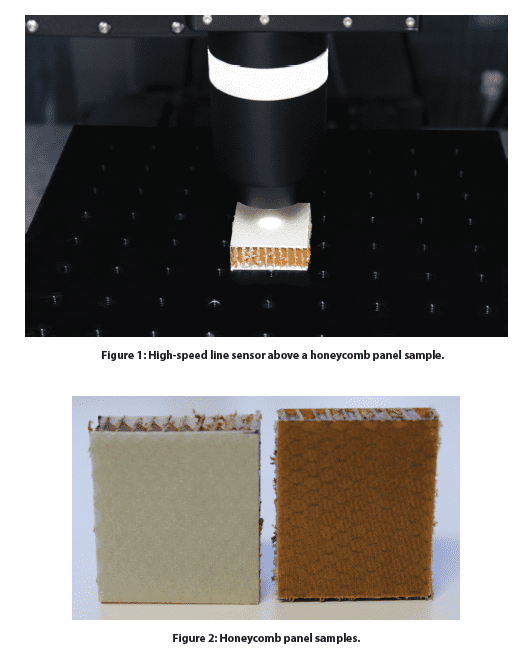

En este estudio, se utilizó la plataforma Nanovea HS2000 equipada con un sensor lineal de alta velocidad para medir y comparar dos paneles alveolares con diferentes acabados superficiales. Presentamos el Nanovea perfilómetro sin contacto’Capacidad para proporcionar mediciones de perfilado 3D rápidas y precisas, así como análisis exhaustivos y detallados del acabado superficial.

RESULTADOS Y DISCUSIÓN

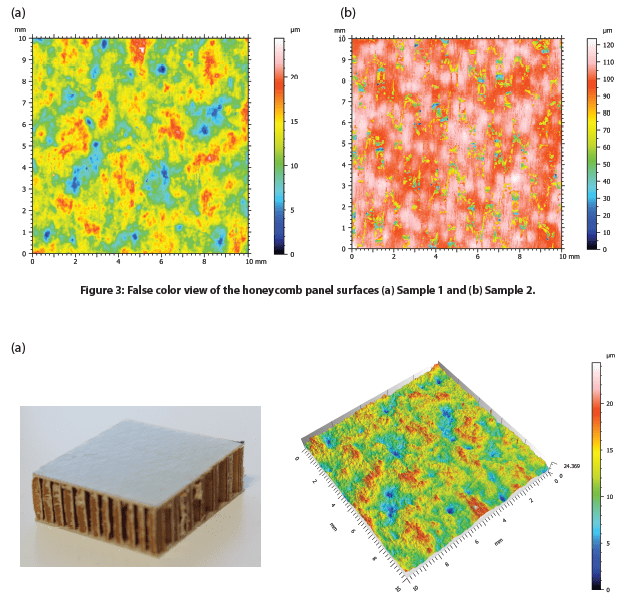

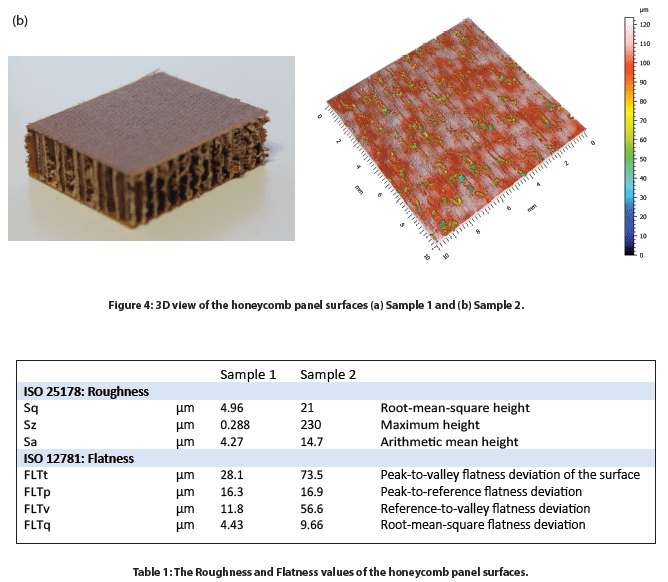

Se midió la superficie de dos muestras de paneles alveolares con diferentes acabados superficiales, denominadas Muestra 1 y Muestra 2. La falsa color y la vista en 3D de las superficies de las Muestras 1 y 2 se muestran en la Figura 3 y la Figura 4, respectivamente. Los valores de rugosidad y planitud se calcularon mediante un software de análisis avanzado y se comparan en la Tabla 1. La muestra 2 presenta una superficie más porosa en comparación con la muestra 1. Como resultado, la muestra 2 posee una rugosidad Sa más alta, de 14,7 µm, en comparación con el valor Sa de 4,27 µm de la muestra 1.

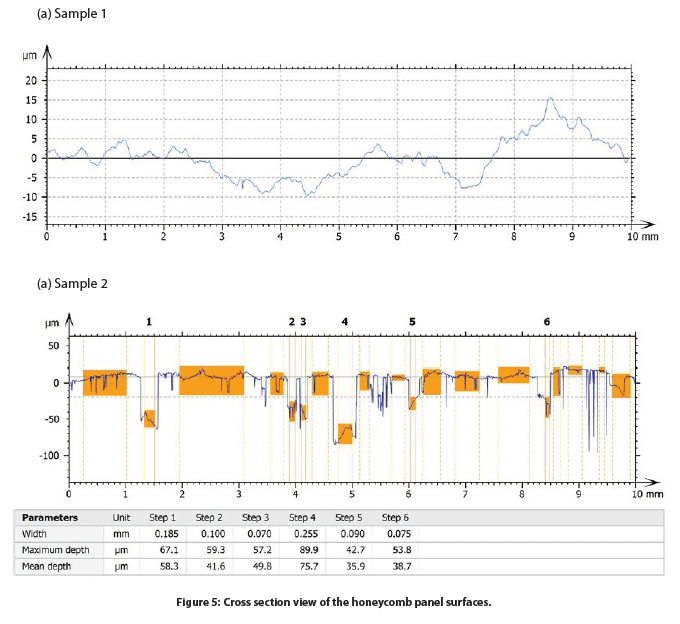

En la figura 5 se comparan los perfiles 2D de las superficies de los paneles alveolares, lo que permite a los usuarios realizar una comparación visual del cambio de altura en diferentes puntos de la superficie de la muestra. Podemos observar que la muestra 1 presenta una variación de altura de ~25 µm entre el pico más alto y el valle más bajo. Por otro lado, la muestra 2 muestra varios poros profundos en todo el perfil 2D. El software de análisis avanzado tiene la capacidad de localizar y medir automáticamente la profundidad de seis poros relativamente profundos, como se muestra en la tabla de la figura 4.b Muestra 2. El poro más profundo de los seis tiene una profundidad máxima de casi 90 µm (paso 4).

Para investigar más a fondo el tamaño y la distribución de los poros de la muestra 2, se realizó una evaluación de la porosidad, cuyos resultados se analizan en la siguiente sección. La vista en corte se muestra en la figura 5 y los resultados se resumen en la tabla 2. Se puede observar que los poros, marcados en color azul en la figura 5, tienen una distribución relativamente homogénea en la superficie de la muestra. El área proyectada de los poros constituye el 18,91 % de la superficie total de la muestra. El volumen por mm² del total de poros es de ~0,06 mm³. Los poros tienen una profundidad media de 42,2 µm y la profundidad máxima es de 108,1 µm.

CONCLUSIÓN

En esta aplicación, hemos demostrado que la plataforma Nanovea HS2000 equipada con un sensor lineal de alta velocidad es una herramienta ideal para analizar y comparar el acabado superficial de muestras de paneles alveolares de forma rápida y precisa. Los escaneos de perfilometría de alta resolución, junto con un software de análisis avanzado, permiten una evaluación completa y cuantitativa del acabado superficial de las muestras de paneles alveolares.

Los datos que se muestran aquí representan solo una pequeña parte de los cálculos disponibles en el software de análisis. Los perfilómetros Nanovea miden prácticamente cualquier superficie para una amplia gama de aplicaciones en los sectores de semiconductores, microelectrónica, energía solar, fibra óptica, automoción, aeroespacial, metalurgia, mecanizado, recubrimientos, farmacéutico, biomédico, medioambiental y muchos otros.

AHORA, HABLEMOS DE SU SOLICITUD

Categorías

- Notas de aplicación

- Bloque sobre tribología anular

- Tribología de la corrosión

- Pruebas de fricción | Coeficiente de fricción

- Pruebas mecánicas a alta temperatura

- Tribología de alta temperatura

- Humedad y gases Tribología

- Humedad Pruebas mecánicas

- Indentación | Fluencia y relajación

- Indentación | Resistencia a la fractura

- Indentación | Dureza y elasticidad

- Indentación | Pérdida y almacenamiento

- Indentación | Esfuerzo frente a deformación

- Indentación | Límite elástico y fatiga

- Pruebas de laboratorio

- Tribología lineal

- Pruebas mecánicas de líquidos

- Tribología de líquidos

- Tribología a baja temperatura

- Pruebas mecánicas

- Comunicado de prensa

- Perfilometría | Planitud y alabeo

- Perfilometría | Geometría y forma

- Perfilometría | Rugosidad y acabado

- Profilometría | Altura y grosor del escalón

- Profilometría | Textura y grano

- Perfilometría | Volumen y área

- Pruebas de perfilometría

- Tribología anillo sobre anillo

- Tribología rotacional

- Prueba de arañazos | Fallo adhesivo

- Prueba del rasguño | Fallo de cohesión

- Pruebas de arañazos | Desgaste en varias pasadas

- Pruebas de rayado | Dureza al rayado

- Pruebas de rayado Tribología

- Pruebas de tribología

- Sin categoría

Archivos

- noviembre 2025

- septiembre 2023

- agosto 2023

- junio 2023

- mayo 2023

- julio 2022

- mayo 2022

- abril 2022

- enero 2022

- diciembre 2021

- noviembre 2021

- octubre 2021

- septiembre 2021

- agosto 2021

- julio 2021

- junio 2021

- mayo 2021

- marzo 2021

- febrero 2021

- diciembre 2020

- noviembre 2020

- octubre 2020

- septiembre 2020

- julio 2020

- mayo 2020

- abril 2020

- marzo 2020

- febrero 2020

- enero 2020

- noviembre 2019

- octubre 2019

- septiembre 2019

- agosto 2019

- julio 2019

- junio 2019

- mayo 2019

- abril 2019

- marzo 2019

- enero 2019

- diciembre 2018

- noviembre 2018

- octubre 2018

- septiembre 2018

- julio 2018

- junio 2018

- abril 2018

- marzo 2018

- febrero 2018

- noviembre 2017

- octubre 2017

- septiembre 2017

- agosto 2017

- junio 2017

- mayo 2017

- marzo 2017

- febrero 2017

- enero 2017

- noviembre 2016

- octubre 2016

- agosto 2016

- julio 2016

- junio 2016

- mayo 2016

- abril 2016

- marzo 2016

- febrero 2016

- enero 2016

- diciembre 2015

- noviembre 2015

- octubre 2015

- septiembre 2015

- agosto 2015

- julio 2015

- junio 2015

- mayo 2015

- abril 2015

- marzo 2015

- febrero 2015

- enero 2015

- noviembre 2014

- octubre 2014

- septiembre 2014

- agosto 2014

- julio 2014

- junio 2014

- mayo 2014

- abril 2014

- marzo 2014

- febrero 2014

- enero 2014

- diciembre 2013

- noviembre 2013

- octubre 2013

- septiembre 2013

- agosto 2013

- julio 2013

- junio 2013

- mayo 2013

- abril 2013

- marzo 2013

- febrero 2013

- enero 2013

- diciembre 2012

- noviembre 2012

- octubre 2012

- septiembre 2012

- agosto 2012

- julio 2012

- junio 2012

- mayo 2012

- abril 2012

- marzo 2012

- febrero 2012

- enero 2012

- diciembre 2011

- noviembre 2011

- octubre 2011

- septiembre 2011

- agosto 2011

- julio 2011

- junio 2011

- mayo 2011

- noviembre 2010

- enero 2010

- abril 2009

- marzo 2009

- enero 2009

- diciembre 2008

- octubre 2008

- agosto 2007

- julio 2006

- marzo 2006

- enero 2005

- abril 2004