Límite elástico y resistencia a la tracción del acero y el aluminio

Importancia de la medición del límite elástico y la resistencia a la tracción máxima mediante indentación

Tradicionalmente, el límite elástico y la resistencia a la tracción máxima se han probado utilizando una gran máquina de ensayo de tracción que requiere una enorme fuerza para separar las muestras de ensayo. Es costoso y lleva mucho tiempo mecanizar adecuadamente muchas muestras de ensayo para un material en el que cada muestra solo se puede probar una vez. Los pequeños defectos en la muestra crean una variación notable en los resultados de las pruebas. Las diferentes configuraciones y alineaciones de los ensayos de tracción disponibles en el mercado a menudo dan lugar a variaciones sustanciales en la mecánica y los resultados de las pruebas.

Objetivo de medición

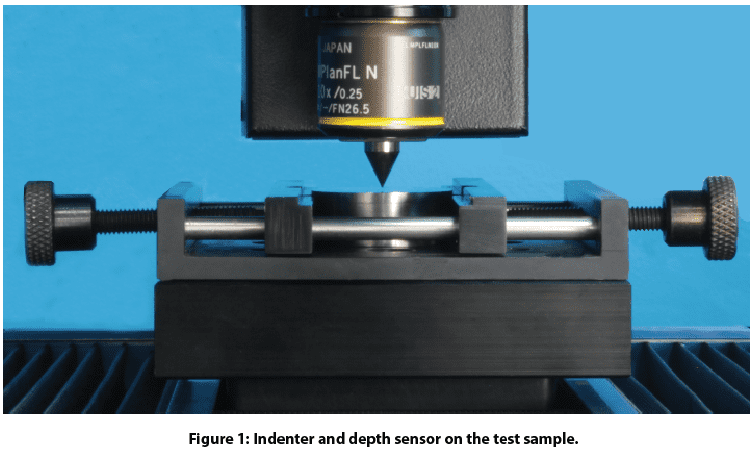

En esta aplicación, Nanovea Comprobador mecánico mide el límite elástico y la resistencia a la tracción máxima de muestras de aleación metálica de acero inoxidable SS304 y aluminio Al6061. Las muestras se seleccionaron por sus valores de límite elástico y resistencia a la tracción máxima comúnmente reconocidos, lo que demuestra la fiabilidad de los métodos de indentación de Nanovea.

Procedimiento de ensayo y procedimientos

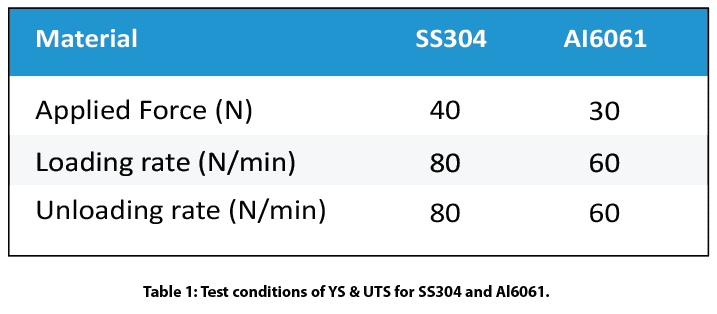

Las pruebas de límite elástico y resistencia a la tracción máxima se realizaron en el ensayador mecánico Nanovea en el Microindentación modo. Para esta aplicación se utilizó una punta de diamante cilíndrica plana de 200 μm de diámetro. Se seleccionaron las aleaciones SS304 y Al6061 por su amplia aplicación industrial y sus valores de límite elástico y resistencia a la tracción máximos comúnmente reconocidos, con el fin de demostrar el gran potencial y la fiabilidad del método de indentación. Las muestras se pulieron mecánicamente hasta obtener un acabado espejo antes de la prueba para evitar que la rugosidad de la superficie o los defectos influyeran en los resultados. Las condiciones de ensayo se enumeran en la tabla 1. Se realizaron más de diez ensayos con cada muestra para garantizar la repetibilidad de los valores de ensayo.

Resultados y debate

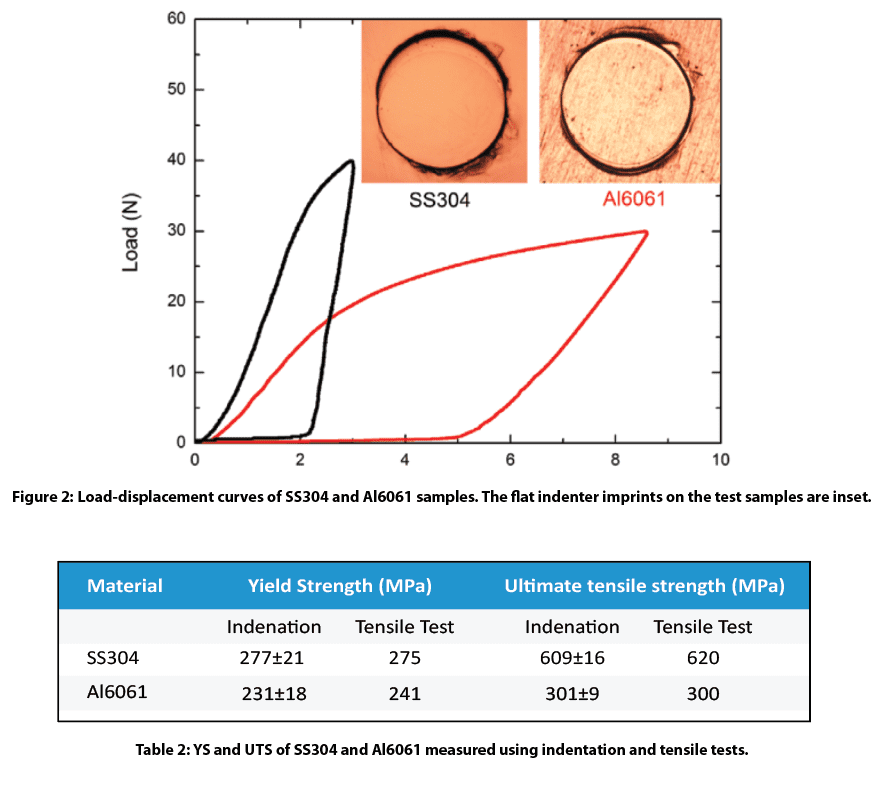

Las curvas de carga-desplazamiento de las muestras de aleación SS304 y Al6061 se muestran en la Figura 3 con las marcas del penetrador plano en las muestras de ensayo insertadas. El análisis de la curva de carga en forma de “S” mediante algoritmos especiales desarrollados por Nanovea calcula el límite elástico y la resistencia a la tracción máxima. Los valores se calculan automáticamente mediante el software, tal y como se resume en la tabla 1. Se incluyen los valores del límite elástico y la resistencia a la tracción máxima obtenidos mediante ensayos de tracción convencionales a efectos comparativos.

Conclusión

En este estudio, mostramos la capacidad del Nanovea Mechanical Tester para evaluar el límite elástico y la resistencia a la tracción máxima de muestras de láminas de acero inoxidable y aleación de aluminio. La sencilla configuración experimental reduce significativamente el tiempo y el costo de preparación de las muestras necesarios para los ensayos de tracción. El pequeño tamaño de la indentación permite realizar múltiples mediciones en una sola muestra. Este método permite realizar mediciones de YS/UTS en muestras pequeñas y áreas localizadas, lo que proporciona una solución para el mapeo de YS/UTS y la detección de defectos locales en tuberías o estructuras automotrices.

Los módulos Nano, Micro o Macro del Nanovea Mechanical Tester incluyen modos de ensayo de indentación, rayado y desgaste que cumplen con las normas ISO y ASTM, lo que proporciona la gama de ensayos más amplia y fácil de usar disponible en un solo sistema. La inigualable gama de Nanovea es la solución ideal para determinar todas las propiedades mecánicas de recubrimientos, películas y sustratos finos o gruesos, blandos o duros, incluyendo la dureza, el módulo de Young, la resistencia a la fractura, la adhesión, la resistencia al desgaste y muchas otras. Además, hay disponibles un perfilador 3D sin contacto y un módulo AFM opcionales para obtener imágenes 3D de alta resolución de la indentación, el rayado y el desgaste, además de otras mediciones de la superficie, como la rugosidad.

Categorías

- Notas de aplicación

- Bloque sobre tribología anular

- Tribología de la corrosión

- Pruebas de fricción | Coeficiente de fricción

- Pruebas mecánicas a alta temperatura

- Tribología de alta temperatura

- Humedad y gases Tribología

- Humedad Pruebas mecánicas

- Indentación | Fluencia y relajación

- Indentación | Resistencia a la fractura

- Indentación | Dureza y elasticidad

- Indentación | Pérdida y almacenamiento

- Indentación | Esfuerzo frente a deformación

- Indentación | Límite elástico y fatiga

- Pruebas de laboratorio

- Tribología lineal

- Pruebas mecánicas de líquidos

- Tribología de líquidos

- Tribología a baja temperatura

- Pruebas mecánicas

- Comunicado de prensa

- Perfilometría | Planitud y alabeo

- Perfilometría | Geometría y forma

- Perfilometría | Rugosidad y acabado

- Profilometría | Altura y grosor del escalón

- Profilometría | Textura y grano

- Perfilometría | Volumen y área

- Pruebas de perfilometría

- Tribología anillo sobre anillo

- Tribología rotacional

- Prueba de arañazos | Fallo adhesivo

- Prueba del rasguño | Fallo de cohesión

- Pruebas de arañazos | Desgaste en varias pasadas

- Pruebas de rayado | Dureza al rayado

- Pruebas de rayado Tribología

- Pruebas de tribología

- Sin categoría

Archivos

- noviembre 2025

- septiembre 2023

- agosto 2023

- junio 2023

- mayo 2023

- julio 2022

- mayo 2022

- abril 2022

- enero 2022

- diciembre 2021

- noviembre 2021

- octubre 2021

- septiembre 2021

- agosto 2021

- julio 2021

- junio 2021

- mayo 2021

- marzo 2021

- febrero 2021

- diciembre 2020

- noviembre 2020

- octubre 2020

- septiembre 2020

- julio 2020

- mayo 2020

- abril 2020

- marzo 2020

- febrero 2020

- enero 2020

- noviembre 2019

- octubre 2019

- septiembre 2019

- agosto 2019

- julio 2019

- junio 2019

- mayo 2019

- abril 2019

- marzo 2019

- enero 2019

- diciembre 2018

- noviembre 2018

- octubre 2018

- septiembre 2018

- julio 2018

- junio 2018

- abril 2018

- marzo 2018

- febrero 2018

- noviembre 2017

- octubre 2017

- septiembre 2017

- agosto 2017

- junio 2017

- mayo 2017

- marzo 2017

- febrero 2017

- enero 2017

- noviembre 2016

- octubre 2016

- agosto 2016

- julio 2016

- junio 2016

- mayo 2016

- abril 2016

- marzo 2016

- febrero 2016

- enero 2016

- diciembre 2015

- noviembre 2015

- octubre 2015

- septiembre 2015

- agosto 2015

- julio 2015

- junio 2015

- mayo 2015

- abril 2015

- marzo 2015

- febrero 2015

- enero 2015

- noviembre 2014

- octubre 2014

- septiembre 2014

- agosto 2014

- julio 2014

- junio 2014

- mayo 2014

- abril 2014

- marzo 2014

- febrero 2014

- enero 2014

- diciembre 2013

- noviembre 2013

- octubre 2013

- septiembre 2013

- agosto 2013

- julio 2013

- junio 2013

- mayo 2013

- abril 2013

- marzo 2013

- febrero 2013

- enero 2013

- diciembre 2012

- noviembre 2012

- octubre 2012

- septiembre 2012

- agosto 2012

- julio 2012

- junio 2012

- mayo 2012

- abril 2012

- marzo 2012

- febrero 2012

- enero 2012

- diciembre 2011

- noviembre 2011

- octubre 2011

- septiembre 2011

- agosto 2011

- julio 2011

- junio 2011

- mayo 2011

- noviembre 2010

- enero 2010

- abril 2009

- marzo 2009

- enero 2009

- diciembre 2008

- octubre 2008

- agosto 2007

- julio 2006

- marzo 2006

- enero 2005

- abril 2004