Medición del acabado superficial del cuero procesado

En esta aplicación, el Nanovea ST400 Perfilómetro se utiliza para medir y comparar el acabado de la superficie de dos muestras de piel diferentes pero procesadas de forma muy similar. Se calcularán automáticamente varios parámetros de la superficie a partir del perfil de la misma. Aquí nos centraremos en la rugosidad de la superficie, la profundidad de los hoyuelos, la distancia entre ellos y su diámetro para realizar una evaluación comparativa.

Acabado superficial del cuero procesado mediante perfilometría 3D

Estos son algunos ejemplos de materiales que hemos probado este mes:

Mecánica:

• Nanoindentación de recubrimientos de níquel.

• Compresión por nanoindentación del adhesivo.

• Nanorrayaduras en recubrimientos cerámicos

• Microindentación del caucho envejecido por el agua de mar.

• Microrrayaduras en recubrimientos anodizados

3D sin contacto Perfilometría:

• Medición de la rugosidad del cuero

• Consistencia de la forma del metal estampado

• Consistencia topográfica del tejido

• Textura de las superficies de plástico moldeado

• Profundidad de los hoyos de la matriz de extrusión

Tribología:

• Tasa de desgaste de los recubrimientos de Ti-MoS2 y WC en condiciones secas, líquidas y de alta temperatura.

Medición in situ del desgaste a alta temperatura mediante tribómetro

La medición del desgaste de la cerámica de silicato de alúmina se simula a alta temperatura de forma controlada y supervisada utilizando el tribómetro Nanovea. En este estudio, nos gustaría mostrar la capacidad del Tribómetro para el monitoreo in situ de la evolución del proceso de desgaste de los materiales a temperaturas elevadas.

Medición in situ del desgaste a alta temperatura mediante tribómetro

Medición de película transparente sobre sustrato transparente

El perfilómetro Nanovea PS50 se utiliza para medir la rugosidad, la altura de los escalones y el espesor óptico de una película transparente delgada sobre un sustrato de vidrio transparente. La altura de los escalones se obtiene midiendo un área de la película y un área donde el sustrato queda expuesto para determinar la diferencia de altura relativa, mientras que el espesor óptico se mide utilizando el ProfilometeCapacidad para medir a través de la película transparente y detectar simultáneamente los reflejos tanto de la superficie superior de la película como del sustrato.

Medición de película transparente sobre sustrato transparente mediante perfilometría 3D

Estos son algunos ejemplos de materiales que hemos probado este mes:

Mecánica:

• Mapeo por nanoindentación de microcomponentes.

• Fractura por nanoindentación de muestras cerámicas.

• Nanoarañazos en vidrio recubierto

• Nano Scratch Fallo de los recubrimientos de los implantes

• Macroindentación de recubrimientos anodizados

• Microarañazos en recubrimientos de uretano acrílico.

• Macroarañazos en muestras de roca.

Perfilometría 3D sin contacto:

• Rugosidad de los microcanales

• Rugosidad de los plásticos curvados

• Textura de micro relieve

• Acabado de recubrimientos en polvo

• Coplanaridad de microcaracterísticas

• Dimensiones de las piezas micro

Tribología:

• Prueba de desgaste lineal de piezas de motor

• Prueba de desgaste rotativo de muestras cerámicas.

COLABORACIÓN PARA MEJORAR LAS PRUEBAS DE ABRASIÓN TABER

Tradicionalmente, la prueba de abrasión Taber se lleva a cabo para evaluar la resistencia al desgaste de los recubrimientos industriales de acuerdo con la norma ASTM D4060. Sin embargo, como se menciona en la norma ASTM D4060, “Para algunos materiales, las pruebas de abrasión que utilizan el abrasímetro Taber pueden estar sujetas a variaciones debido a cambios en las características abrasivas de la rueda durante la prueba”. Esto puede dar lugar a una mala reproducibilidad de los resultados de las pruebas y crear dificultades para comparar los valores comunicados por diferentes laboratorios. Además, en la prueba de abrasión Taber, la resistencia a la abrasión se calcula como la pérdida de peso en un número específico de ciclos de abrasión. Sin embargo, por ejemplo, las pinturas acrílicas de uretano para suelos tienen un espesor de película seca recomendado de 37,5-50 μm. El agresivo proceso de abrasión del abrasómetro Taber puede desgastar rápidamente el recubrimiento de uretano acrílico y provocar una pérdida de masa en el sustrato, lo que da lugar a errores sustanciales en el cálculo de la pérdida de peso de la pintura. La implantación de partículas abrasivas en la pintura durante la prueba de abrasión también contribuye a los errores. Por lo tanto, es fundamental realizar una medición cuantificable y fiable bien controlada para garantizar una evaluación reproducible del desgaste, como por ejemplo Tribómetro.

Más información en la nota de aplicación de este mes: Evaluación del desgaste y los rayones en recubrimientos industriales

Medición del acabado del recubrimiento en polvo mediante perfilometría 3D

En esta aplicación, el Nanovea ST400 Perfilómetro Se utiliza para medir y comparar el acabado superficial de cuatro muestras diferentes de recubrimiento en polvo. Se calcularán automáticamente varios parámetros superficiales a partir del perfil del recubrimiento. Aquí nos centraremos en la superficie. Rugosidad, Pico a valle y superficie para evaluación comparativa.

Medición del acabado del recubrimiento en polvo mediante perfilometría 3D

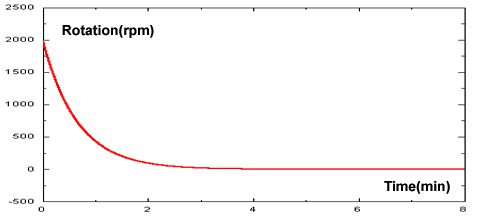

AVANCES EN LAS PRUEBAS DE LUBRICACIÓN: ¡MEDICIÓN CONTINUA DE LA CURVA DE STRIBECK!

Irvine, California, 24 de octubre de 2013. Nanovea demuestra por primera vez su capacidad para medir una curva de Stribeck continua. Utilizando el Nanovea Tribómetro Control avanzado de velocidad, de 2000 a 0,01 rpm, en 10 minutos. El software de monitorización proporciona una curva de Stribeck completa. Antes de este avance, las pruebas de lubricación de una curva de Stribeck se evaluaban de forma gradual, lo que requería la unión de datos. Este avance proporciona datos precisos a lo largo de toda la evaluación del régimen de lubricación y reduce considerablemente el tiempo y el costo. La prueba también muestra un gran potencial para su uso en diferentes aplicaciones de ingeniería industrial.

Más información en la nota de aplicación de este mes: Medición continua de la curva de Stribeck mediante tribómetro

Medición continua de la curva de Stribeck mediante tribómetro

Las curvas de Stribeck se midieron utilizando dos aceites lubricantes con diferentes viscosidades cinéticas para compararlos. Se utilizó el tribómetro Nanovea Pin-On-Disk equipado con el módulo de lubricación. La velocidad de rotación disminuyó a un ritmo exponencial de 2000 a 0,01 rpm para mostrar la medición continua de la curva de Stribeck y la sensibilidad precisa del Tribómetro capacidades.

Medición continua de la curva de Stribeck mediante tribómetro

Estos son algunos ejemplos de materiales que hemos probado este mes:

Mecánica:

• Nanoindentación DMA de películas poliméricas.

• Compresión por nanoindentación de microcaracterísticas.

• Fluencia por nanoindentación de compuestos

• Nanoarañazos en recubrimientos de microcables

• Microarañazos en recubrimientos anodizados

• Fallo por macroindentación multiciclo de microcomponentes.

• Arañazos macro de recubrimientos epoxi.

3D sin contacto Perfilometría:

• Rugosidad de los recubrimientos anodizados

• Medición de texturas mediante micrograbado láser

• Planitud de las bandejas de ADN

• Altura de los escalones de las piezas de automóvil

• Dimensiones de la rejilla de obleas

Tribología:

• Prueba de desgaste de recubrimientos anodizados

• Pruebas de desgaste de recubrimientos epoxi.

• Análisis de la curva de Stribeck de muestras de petróleo.