Caracterización de la superficie de escamas de pez mediante perfilometría 3D

En esta aplicación, el Nanovea ST400 Perfilómetro Se utiliza para escanear toda la superficie de la escala, junto con un escaneo más pequeño y de mayor resolución en el centro de la escala. También se midió la rugosidad de la superficie exterior e interior de la escala para compararlas.

Caracterización de la superficie de las escamas de pescado mediante perfilometría 3D

Propiedades mecánicas y tribológicas de la fibra de carbono

Combinado con la prueba de desgaste por Tribómetro y análisis de superficies mediante perfilómetro óptico 3D, nos

mostrar la versatilidad y precisión de los instrumentos Nanovea en el ensayo de materiales compuestos

con propiedades mecánicas direccionales.

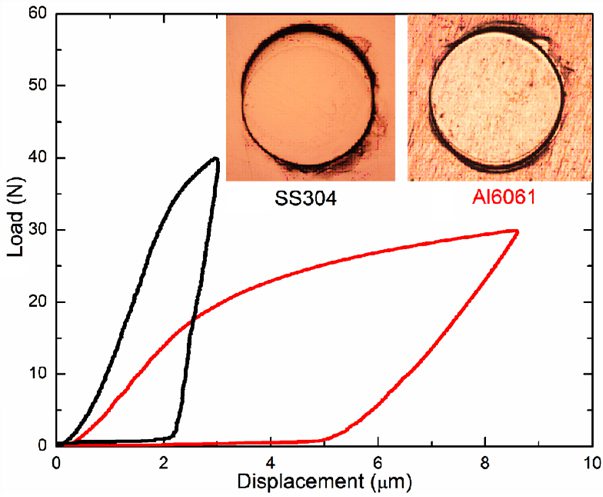

Medición innovadora probada en acero y aluminio

Por primera vez, Nanovea ha desarrollado un método revolucionario para obtener de forma fiable tanto el límite elástico (YS) como la resistencia a la tracción máxima (UTS) a través del técnica de sangría; lo que supone importantes ventajas en comparación con los ensayos de tracción tradicionales. Más información en la actualización de este mes. nota de aplicación.

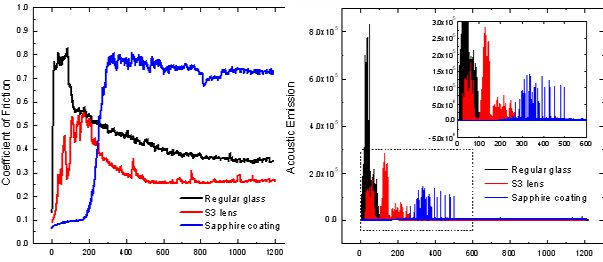

Uso de la emisión acústica (AE) durante las pruebas de desgaste

Durante Tribómetro En las pruebas de desgaste, el proceso de fricción constante de la contrapieza contra la muestra de prueba genera una serie de eventos, como deformación, agrietamiento, abrasión, transformación de fase y eliminación de material. Estos eventos de liberación rápida de tensión son las fuentes de AE. Una medición cuantificable y confiable de AE puede proporcionar más información sobre el mecanismo de falla por desgaste. Obtenga más información en este mes. nota de aplicación.

Vidrio para pruebas de desgaste con control de emisiones acústicas

Se compara el comportamiento frente al desgaste de tres tipos de vidrio (vidrio normal, vidrio Galaxy S3 y vidrio recubierto de zafiro) de forma controlada y supervisada utilizando Nanovea. Tribómetro equipado con un detector AE. En este estudio, nos gustaría mostrar la aplicación de la detección AE durante el desgaste y su correlación con la evolución del coeficiente de fricción (COF).

Vidrio para pruebas de desgaste con control de emisiones acústicas

Estos son algunos ejemplos de materiales que hemos probado este mes:

Mecánica:

• Nanoindentación de alambre de cobre micro

• Nanoindentación de recubrimientos metálicos sobre plástico.

• Compresión por nanoindentación de partículas.

• Mapeo por microindentación de implantes dentales.

• Dureza al rayado de las cubiertas electrónicas

Perfilometría 3D sin contacto:

• Topografía de artefactos arqueológicos

• Rugosidad del poliuretano

• Dimensiones: bordes afilados

• Coplanaridad de los componentes electrónicos

• Espesor de los recubrimientos

• Volumen y área de corrosión.

Tribología:

• Prueba de fricción de correas de poliuretano reforzado

• Prueba de fricción entre polímeros

• Pruebas de desgaste de polímeros duros

• Prueba de desgaste del acero tratado

Estos son algunos ejemplos de materiales que hemos probado este mes:

Mecánica:

• Nanoindentación del material de las lentes intraoculares.

• Límite elástico de nanoindentación de micro muestras

• Nanoarañazos en cables recubiertos de teflón.

• Microrrayaduras en muestras litográficas.

• Microrrayaduras en recubrimientos cerámicos

Perfilometría 3D sin contacto:

• Topografía de las semillas

• Rugosidad de la luminaria LED

• Rugosidad del acero cortado con láser

• Rugosidad del implante de cadera

• Pérdida de volumen de las muestras de perspex desgastadas.

Tribología:

• Prueba de la curva de Stribeck con muestras de lubricación calentadas.

• Pruebas de desgaste de recubrimientos anodizados.

• Pruebas de desgaste de recubrimientos DLC

Perfilómetro compacto rediseñado y probador mecánico

Las mejoras introducidas en el perfilómetro PS50 y en el comprobador mecánico compacto ponen de manifiesto el compromiso de Nanovea con la mejora continua. Estas dos opciones de gama alta para principiantes se han rediseñado con nuevas bases para adaptarlas al estándar de Nanovea. El PS50 Perfilómetro y compacto Comprobador mecánico proporcionan una precisión y capacidad sin igual en cada una de sus respectivas clases.

Propiedades mecánicas del vidrio de los teléfonos inteligentes

En este estudio, se utiliza el Nanovea Mechanical Tester para realizar un estudio exhaustivo de las propiedades tribomecánicas.

Propiedades de una lente de teléfono inteligente, incluyendo la dureza, el módulo de Young y la resistencia a la fractura, así como la resistencia a los rayones y al desgaste, con el fin de demostrar la versatilidad y precisión del probador mecánico Nanovea en las pruebas de muestras de vidrio.

Propiedades mecánicas del vidrio de los teléfonos inteligentes