Acabado dimensional y superficial de los tubos poliméricos

Importancia del análisis dimensional y superficial de los tubos poliméricos

Los tubos fabricados con material polimérico se utilizan habitualmente en muchos sectores, como el automovilístico, el médico, el eléctrico y muchos otros. En este estudio, se analizaron catéteres médicos fabricados con diferentes materiales poliméricos utilizando Nanovea. Perfilómetro 3D sin contacto para medir la rugosidad, la morfología y las dimensiones de la superficie. La rugosidad de la superficie es crucial para los catéteres, ya que muchos de los problemas que estos presentan, como infecciones, traumatismos físicos e inflamaciones, pueden estar relacionados con la superficie del catéter. Las propiedades mecánicas, como el coeficiente de fricción, también pueden estudiarse observando las propiedades de la superficie. Estos datos cuantificables pueden obtenerse para garantizar que el catéter pueda utilizarse en aplicaciones médicas.

En comparación con la microscopía óptica y la microscopía electrónica, la perfilometría 3D sin contacto que utiliza cromatismo axial es muy recomendable para caracterizar las superficies de los catéteres debido a su capacidad para medir ángulos/curvaturas, medir superficies de materiales a pesar de su transparencia o reflectividad, la mínima preparación de muestras y su naturaleza no invasiva. A diferencia de la microscopía óptica convencional, se puede obtener la altura de la superficie y utilizarla para el análisis computacional; por ejemplo, para encontrar dimensiones y eliminar formas para determinar la rugosidad de la superficie. Al requerir poca preparación de la muestra, en contraste con la microscopía electrónica, y al ser de naturaleza no invasiva, también permite una rápida recopilación de datos sin temor a la contaminación y los errores derivados de la preparación de la muestra.

Objetivo de medición

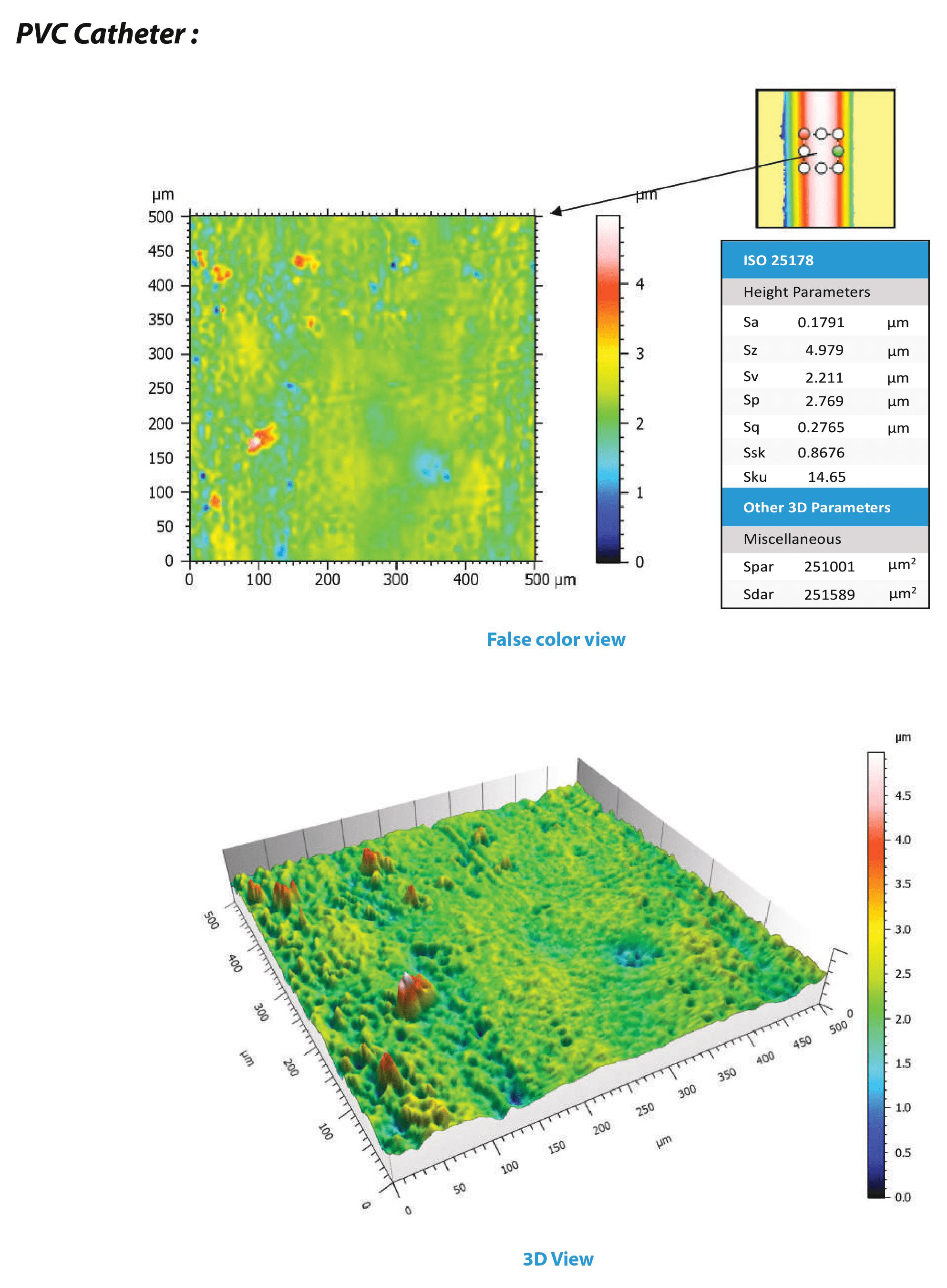

En esta aplicación, se utiliza el perfilómetro sin contacto Nanovea 3D para escanear la superficie de dos catéteres: uno fabricado en TPE (elastómero termoplástico) y otro en PVC (cloruro de polivinilo). Se obtendrán y compararán los parámetros de morfología, dimensión radial y altura de los dos catéteres.

Resultados y debate

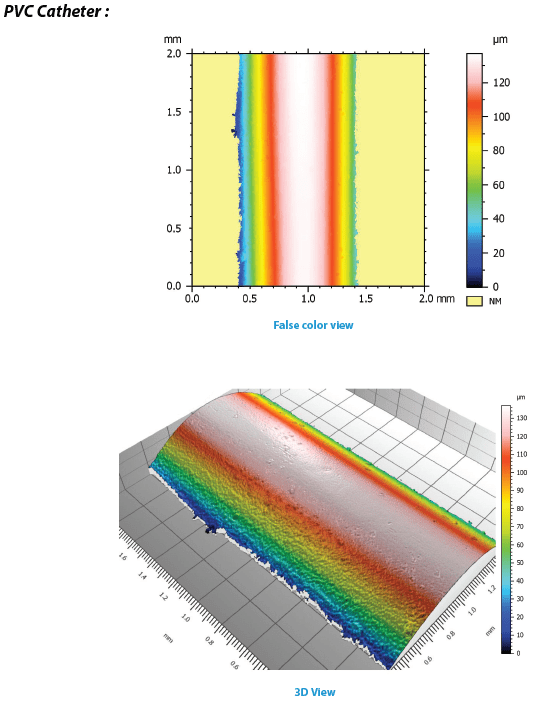

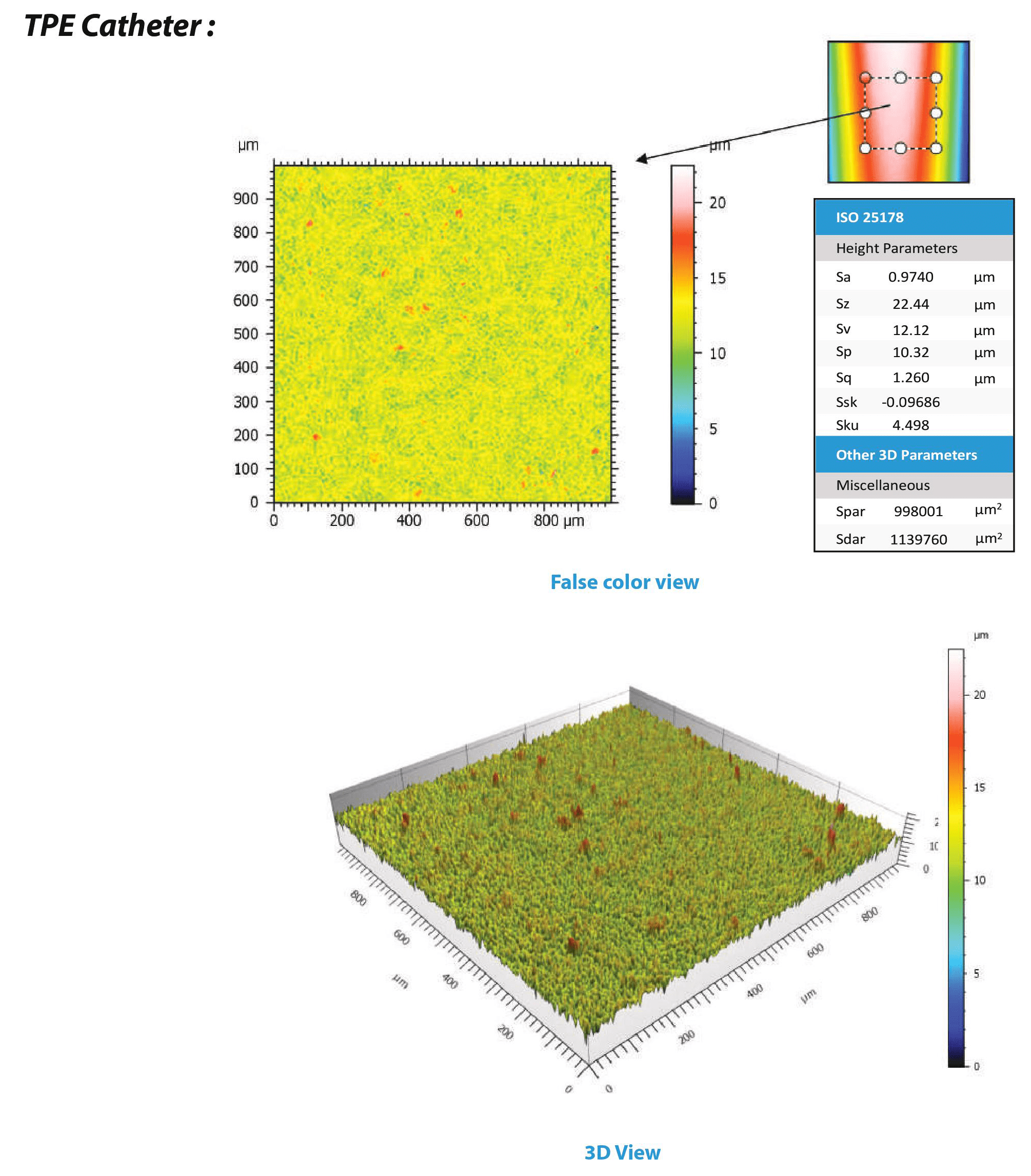

Superficie 3D

A pesar de la curvatura de los tubos poliméricos, el perfilómetro sin contacto Nanovea 3D puede escanear la superficie de los catéteres. A partir del escaneo realizado, se puede obtener una imagen 3D para una inspección visual rápida y directa de la superficie.

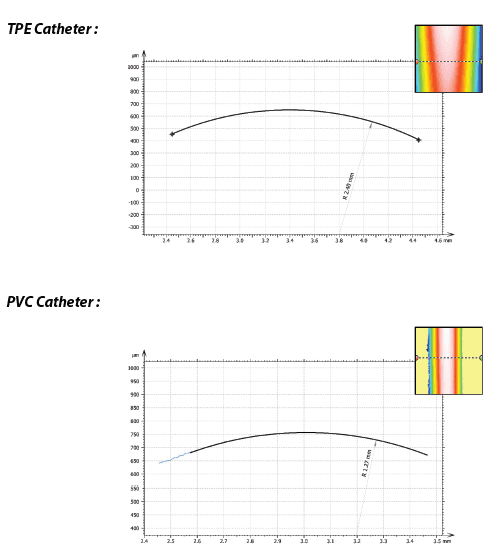

La dimensión radial exterior se obtuvo extrayendo un perfil del escaneo original y ajustando un arco al perfil. Esto demuestra la capacidad del perfilómetro 3D sin contacto para realizar análisis dimensionales rápidos para aplicaciones de control de calidad. También se pueden obtener fácilmente múltiples perfiles a lo largo de la longitud del catéter.

La dimensión radial exterior se obtuvo extrayendo un perfil del escaneo original y ajustando un arco al perfil. Esto demuestra la capacidad del perfilómetro 3D sin contacto para realizar análisis dimensionales rápidos para aplicaciones de control de calidad. También se pueden obtener fácilmente múltiples perfiles a lo largo de la longitud del catéter.

Conclusión

En esta aplicación, hemos mostrado cómo se puede utilizar el perfilómetro sin contacto Nanovea 3D para caracterizar tubos poliméricos. En concreto, se obtuvieron datos de metrología superficial, dimensiones radiales y rugosidad superficial de catéteres médicos. Se determinó que el radio exterior del catéter de TPE era de 2,40 mm, mientras que el del catéter de PVC era de 1,27 mm. Se observó que la superficie del catéter de TPE era más rugosa que la del catéter de PVC. El Sa del TPE era de 0,9740 µm, en comparación con los 0,1791 µm del PVC. Aunque para esta aplicación se utilizaron catéteres médicos, la perfilometría 3D sin contacto también se puede aplicar a una gran variedad de superficies. Los datos y cálculos que se pueden obtener no se limitan a los que se muestran.

AHORA, HABLEMOS DE SU SOLICITUD

Categorías

- Notas de aplicación

- Bloque sobre tribología anular

- Tribología de la corrosión

- Pruebas de fricción | Coeficiente de fricción

- Pruebas mecánicas a alta temperatura

- Tribología de alta temperatura

- Humedad y gases Tribología

- Humedad Pruebas mecánicas

- Indentación | Fluencia y relajación

- Indentación | Resistencia a la fractura

- Indentación | Dureza y elasticidad

- Indentación | Pérdida y almacenamiento

- Indentación | Esfuerzo frente a deformación

- Indentación | Límite elástico y fatiga

- Pruebas de laboratorio

- Tribología lineal

- Pruebas mecánicas de líquidos

- Tribología de líquidos

- Tribología a baja temperatura

- Pruebas mecánicas

- Comunicado de prensa

- Perfilometría | Planitud y alabeo

- Perfilometría | Geometría y forma

- Perfilometría | Rugosidad y acabado

- Profilometría | Altura y grosor del escalón

- Profilometría | Textura y grano

- Perfilometría | Volumen y área

- Pruebas de perfilometría

- Tribología anillo sobre anillo

- Tribología rotacional

- Prueba de arañazos | Fallo adhesivo

- Prueba del rasguño | Fallo de cohesión

- Pruebas de arañazos | Desgaste en varias pasadas

- Pruebas de rayado | Dureza al rayado

- Pruebas de rayado Tribología

- Pruebas de tribología

- Sin categoría

Archivos

- noviembre 2025

- septiembre 2023

- agosto 2023

- junio 2023

- mayo 2023

- julio 2022

- mayo 2022

- abril 2022

- enero 2022

- diciembre 2021

- noviembre 2021

- octubre 2021

- septiembre 2021

- agosto 2021

- julio 2021

- junio 2021

- mayo 2021

- marzo 2021

- febrero 2021

- diciembre 2020

- noviembre 2020

- octubre 2020

- septiembre 2020

- julio 2020

- mayo 2020

- abril 2020

- marzo 2020

- febrero 2020

- enero 2020

- noviembre 2019

- octubre 2019

- septiembre 2019

- agosto 2019

- julio 2019

- junio 2019

- mayo 2019

- abril 2019

- marzo 2019

- enero 2019

- diciembre 2018

- noviembre 2018

- octubre 2018

- septiembre 2018

- julio 2018

- junio 2018

- abril 2018

- marzo 2018

- febrero 2018

- noviembre 2017

- octubre 2017

- septiembre 2017

- agosto 2017

- junio 2017

- mayo 2017

- marzo 2017

- febrero 2017

- enero 2017

- noviembre 2016

- octubre 2016

- agosto 2016

- julio 2016

- junio 2016

- mayo 2016

- abril 2016

- marzo 2016

- febrero 2016

- enero 2016

- diciembre 2015

- noviembre 2015

- octubre 2015

- septiembre 2015

- agosto 2015

- julio 2015

- junio 2015

- mayo 2015

- abril 2015

- marzo 2015

- febrero 2015

- enero 2015

- noviembre 2014

- octubre 2014

- septiembre 2014

- agosto 2014

- julio 2014

- junio 2014

- mayo 2014

- abril 2014

- marzo 2014

- febrero 2014

- enero 2014

- diciembre 2013

- noviembre 2013

- octubre 2013

- septiembre 2013

- agosto 2013

- julio 2013

- junio 2013

- mayo 2013

- abril 2013

- marzo 2013

- febrero 2013

- enero 2013

- diciembre 2012

- noviembre 2012

- octubre 2012

- septiembre 2012

- agosto 2012

- julio 2012

- junio 2012

- mayo 2012

- abril 2012

- marzo 2012

- febrero 2012

- enero 2012

- diciembre 2011

- noviembre 2011

- octubre 2011

- septiembre 2011

- agosto 2011

- julio 2011

- junio 2011

- mayo 2011

- noviembre 2010

- enero 2010

- abril 2009

- marzo 2009

- enero 2009

- diciembre 2008

- octubre 2008

- agosto 2007

- julio 2006

- marzo 2006

- enero 2005

- abril 2004