NANOINDENTATION & SCRATCH TESTING

LAB SERVICES & CONSULTING

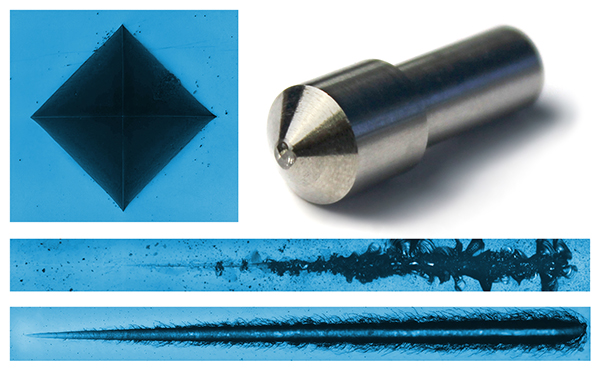

Nanoindentation testing and scratch testing are methods to characterize material mechanical properties on micro to nano scales. Test methods include micro to nano-indentation testing for comparative and quantitative hardness and elastic modulus determination, stress and strain analysis, DMA and CSM testing and scratch testing for evaluation of wear resistance, marring, cracking and film adhesion and cohesion.

Nanoindentation testing and scratch testing can be performed in conjunction with non-contact optical profilometer integration. NANOVEA profilometers use Chromatic Confocal technology, which uses wavelengths of light to accurately determine physical height. A variety of indenters and environmental modules are available for testing. A force-displacement curve obtained during indentation also provides indications of the sample material’s mechanical and physical properties.

NANOVEA has been redefining international standards in quality control and materials engineering for over two decades. This unmatched in-depth experience we have acquired throughout all industries and applications is now available to you in the form of lab testing services and personal consultations.

MECHANICAL

TESTING

NANO & MICRO

MICRO & NANOINDENTATION TESTING

Hardness & Elastic Modulus

Stress vs Strain Analysis

DMA / CSM Testing

Storage & Loss Modulus

Ultimate Yield Strength

SCRATCH TESTING

Adhesion & Cohesion Failure

Scratch Hardness

Surface Marring & Cracking

Films / Coatings / Paints

STANDARD

ASTM E2546

ASTM E384

ASTM C1624

ASTM D7968

and other ISO & ASTM standards

Indentation

Hardness & Elastic Modulus

Fracture Toughness

Yield Strength & Fatigue

Creep & Relaxation

Stress vs Strain

Loss & Storage Modulus

ENVIRONMENTAL MODULES

HIGH TEMP

LOW TEMP

LIQUID

HUMIDITY

VACUUM

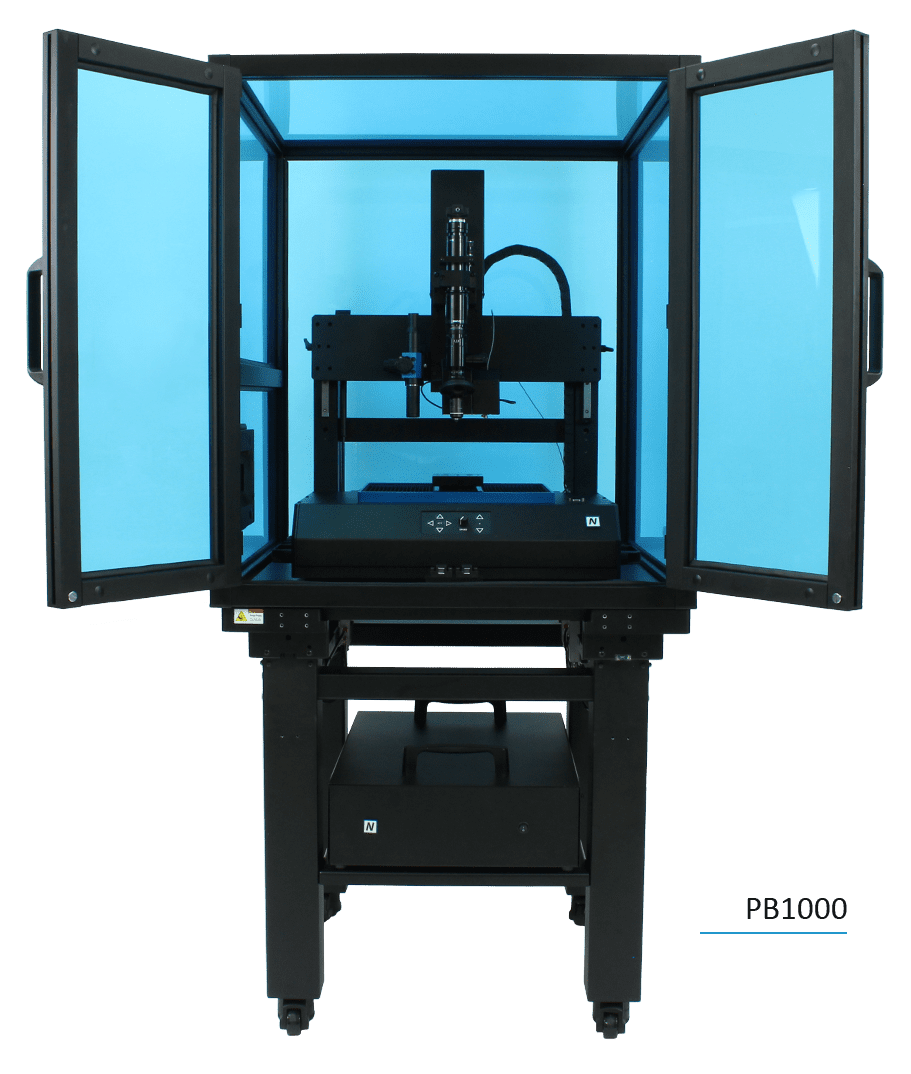

The Most Advanced Mechanical Testers

Nano Piezo Technology

Fully Automated

NANOVEA

MECHANICAL TESTERS

NANOVEA Mechanical Testers are the most versatile instrumented indentation and scratch testers capable of precisely measuring the nanomechanical properties of wide ranges of materials from thin films, coatings, ceramics and composites to polymers and bio materials via Indentation, Scratch and Friction testing.

All NANOVEA Mechanical Tester models come with true feedback load control from independent load and depth sensors that provide unmatched accuracy and the highest repeatability available on the market. This technology allows a user to perform Nanoindentation and Microindentation for Hardness and Elastic Modulus Testing, Stress vs Strain Analysis, Creep and Relaxation, Loss and Storage Modulus, Yield Strength and Fatigue, Fracture Toughness and Nano-scratch & Micro-scratch for Scratch Hardness Testing, Multi-pass Wear Test, Cohesive and Adhesive Failure Testing as well as Coefficient of Friction testing, all available on one system.

NANOVEA Mechanical Testers are a culmination of over 25 years of experience empowering materials testing and quality control in companies all over the world.

NANOVEA designs and manufactures instruments for materials testing and quality control.

Our Profilometers, Tribometers and Mechanical Testers can be found in renowned education and industrial organizations around the world.

For over 25 years, researchers and companies dealing with the most demanding applications have been relying on our unmatched range of consulting and materials testing services.

PROFILOMETERS

Chromatic Light technology for highest accuracy on any surface, any material.

MECHANICAL TESTERS

The highest accuracy and repeatability with the lowest cost of ownership.

TRIBOMETERS

Highly accurate and repeatable wear and friction testing.