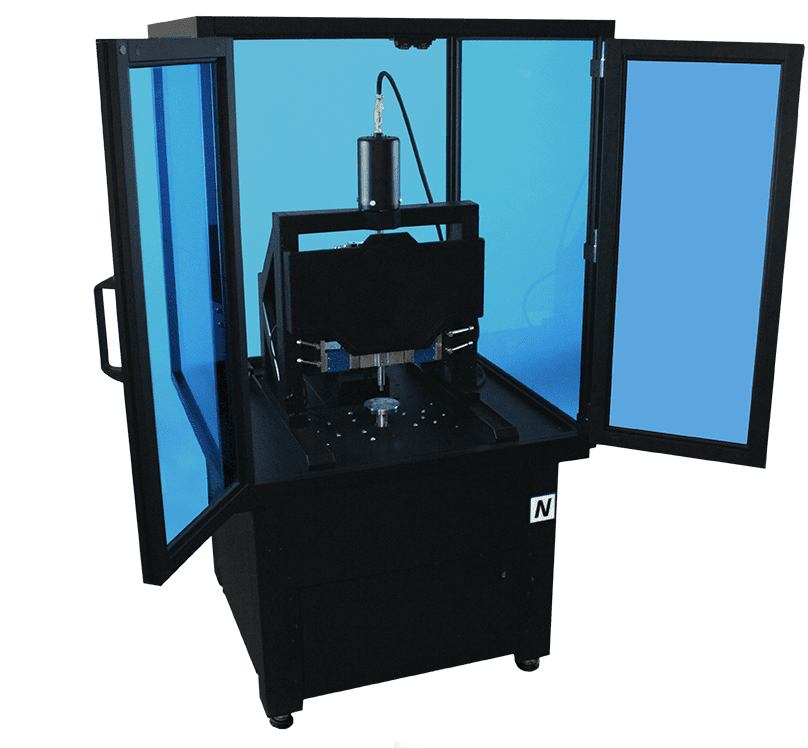

Rotational Module

Previous

Next

Rotational Wear Friction Test reproduces the rotational motion found in many real-world tribology mechanisms.

How does it work?

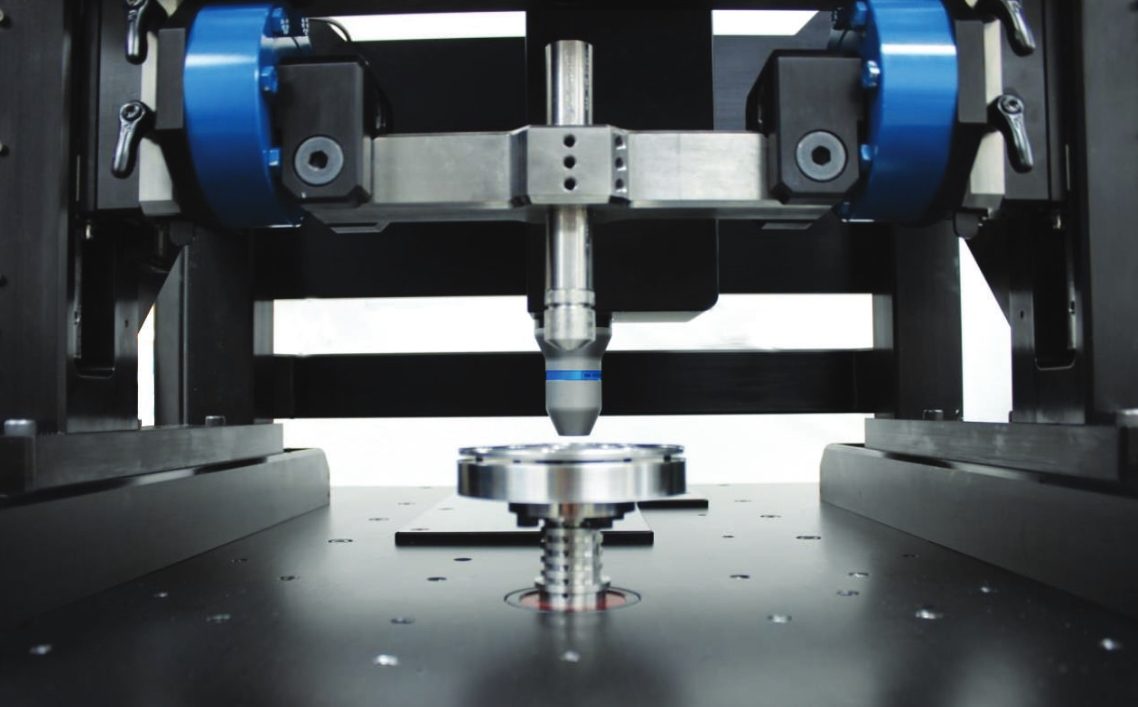

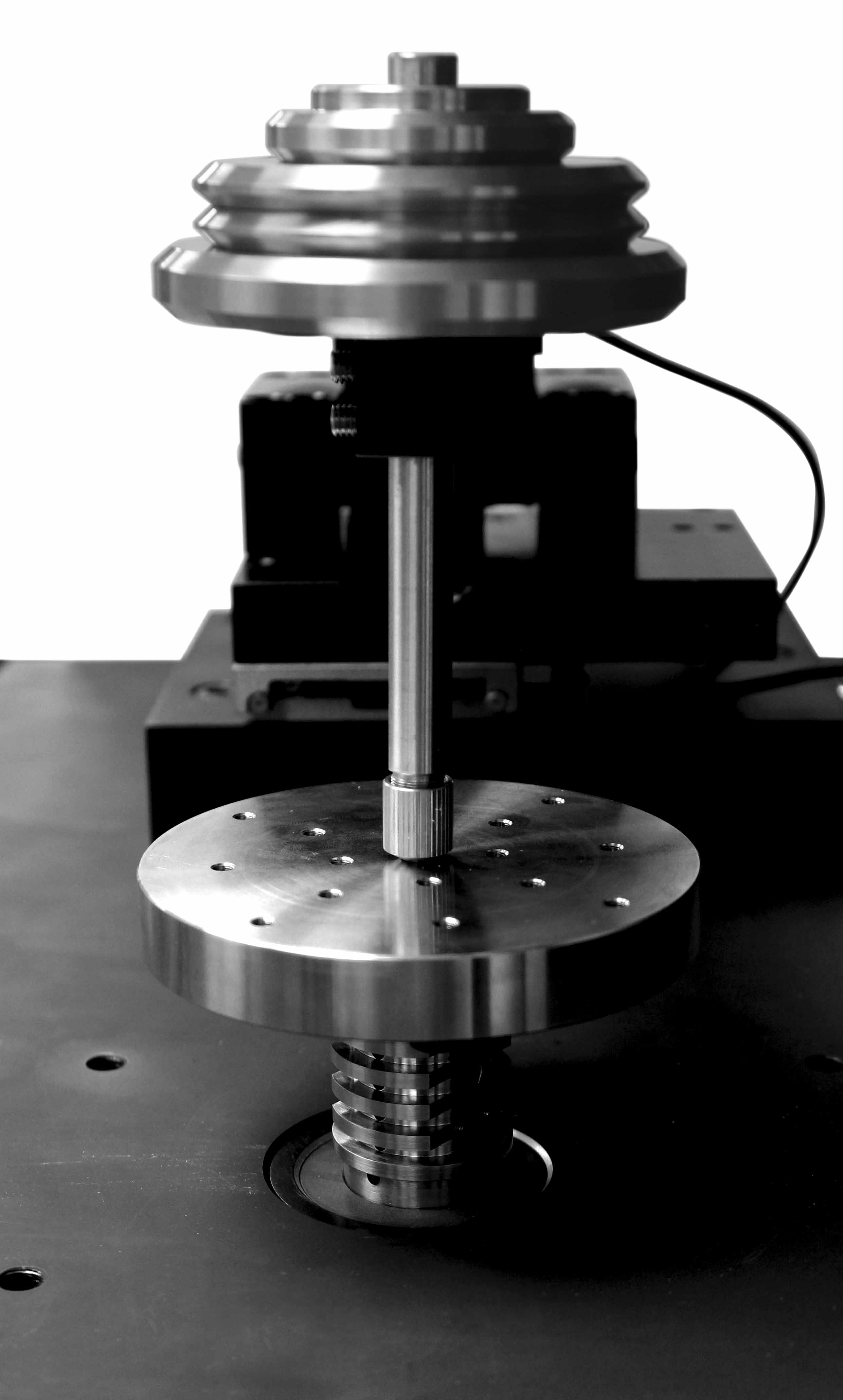

A pin or ball tip is loaded onto a test sample with precise weight and at a specific position from the center of rotation.

As the sample starts rotating, the tip creates a rotational wear track.

An arc test (back and forth) can also be performed at a specific degree

range.

Extreme Versatility

STANDARDS

- ASTM D3702

- ASTM D2266

- ASTM D4172

- ASTM G132

- ASTM G99

* Instrument parameter limits may differ

from those specified within the standard.

Properties Analyzed

- Friction Coefficient

- Wear Rates

- Failure Points

- Electrical Resistance

- Lubrication Studies

- Friction vs Speed

- Stribeck Curve

- Scratch Hardness

- Static Coefficient of friction

- Friction versus load (T2000)

- Spiral Test at a constant linear speed

- Semi-Linear (back and forth) Wear and Friction at specific angles

- Friction and wear distribution across the lap

SENSORS

- Depth

- Acoustic Emission

- Electrical Resistance

Rotating Lower Sample

- Samples with flat surface for the test

Fixed Upper Sample

- 3, 6, 10 and 25mm ball

- Custom ball sizes

- Custom Pins

- Flat Plate

- Custom geometries

- Diamond, WC, Rubber and many other materials

Environmental Conditions

- Fully Removable 1000°C Oven

- Cooling down to – 150°C

- Liquid Cup & Liquid Heating to 150°C

- Lubrication Drop by Drop

- Humidity Control

- Various Gases

- Vacuum (Custom)