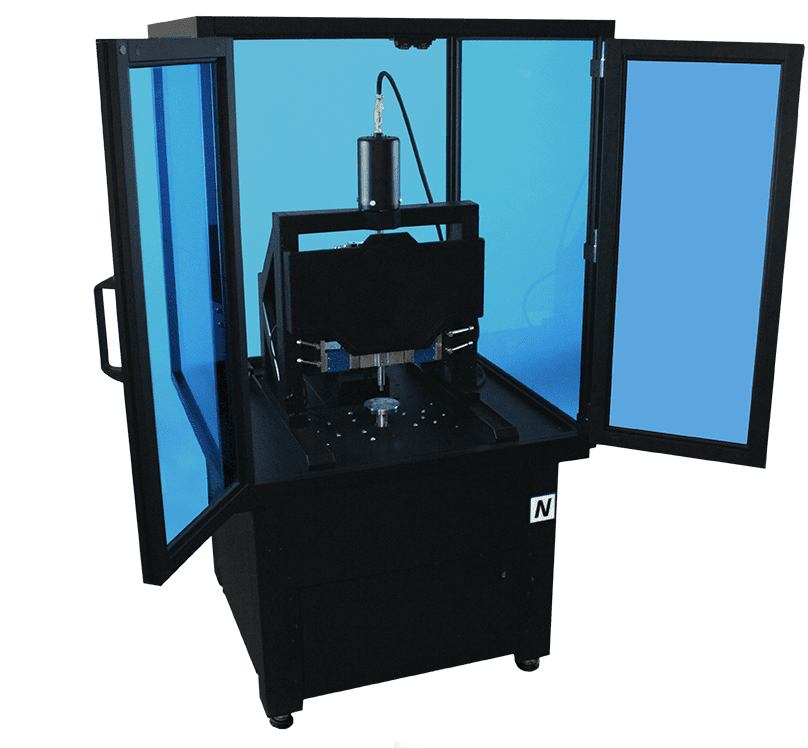

Módulo de rotación

Anteriormente

Siguiente

La prueba de fricción por desgaste rotativo reproduce el movimiento rotativo que se encuentra en muchos mecanismos tribológicos del mundo real.

¿Cómo funciona?

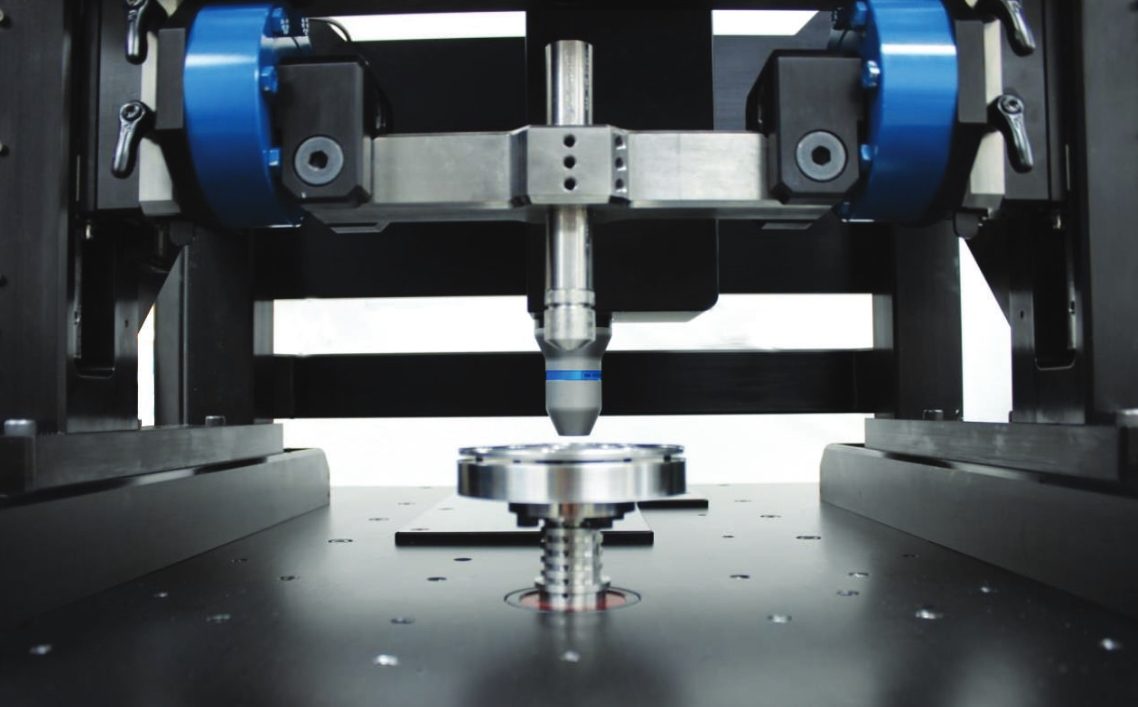

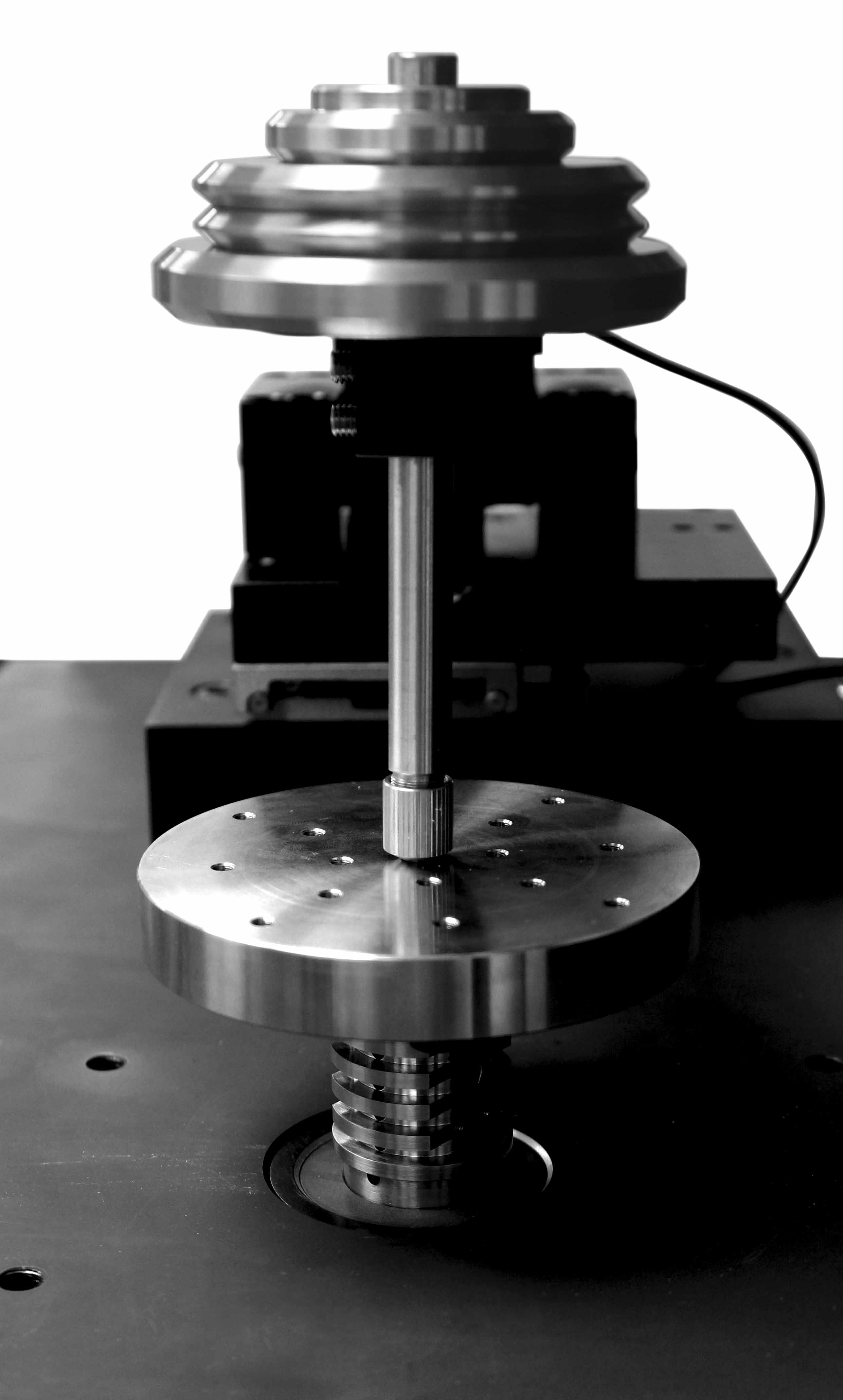

Se carga un pasador o una punta de bola en una muestra de prueba con un peso preciso y en una posición específica desde el centro de rotación.

Cuando la muestra comienza a girar, la punta crea una pista de desgaste rotacional.

También se puede realizar una prueba de arco (de ida y vuelta) en un grado específico

.

Extrema Versatilidad

NORMAS

- ASTM D3702

- ASTM D2266

- ASTM D4172

- ASTM G132

- ASTM G99

* Los límites de los parámetros del instrumento pueden ser diferentes

de los especificados en la norma.

Propiedades Analizadas

- Coeficiente de fricción

- Índices de desgaste

- Puntos de fallo

- Resistencia eléctrica

- Estudios de lubricación

- Fricción frente a la velocidad

- Curva Stribeck

- Dureza al Rayado

- Coeficiente de fricción estático

- Fricción en función de la carga (T2000)

- Prueba en espiral a velocidad lineal constante

- Desgaste y fricción semilineal (de ida y vuelta) en ángulos específicos

- Distribución de la Fricción y el Desgaste en la vuelta

SENSORES

- Profundidad

- Emisión acústica

- Resistencia eléctrica

Muestra inferior giratoria

- Muestras con superficie plana para la prueba

Muestra superior fija

- Bola de 3, 6, 10 y 25 mm

- Tamaños de bolas personalizados

- Pins personalizados

- Placa plana

- Geometrías personalizadas

- Diamante, WC, caucho y muchos otros materiales

Condiciones Ambientales

- Horno de 1000°C totalmente desmontable

- Enfriamiento hasta - 150°C

- Copa de líquido y calentamiento de líquido a 150°C

- Lubricación gota a gota

- Control de la humedad

- Varios gases

- Vacío (personalizado)