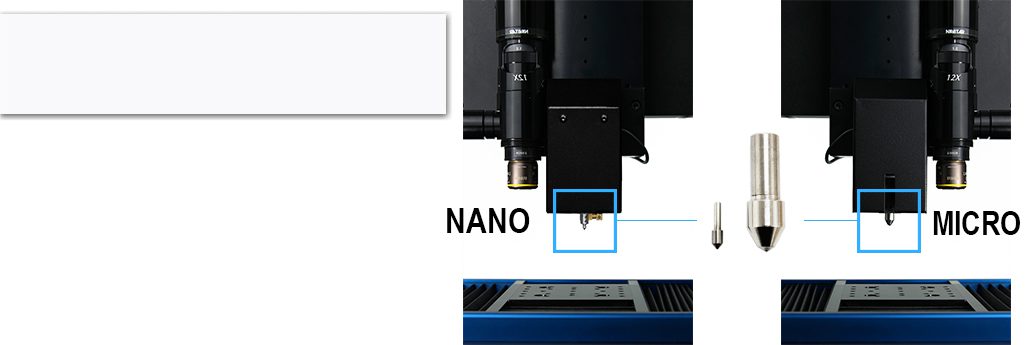

MICRO MODULE

Mechanical Testers | Nano Module | Application Notes

Now the world’s leading micro mechanical testing. Automatic, accurate and fast hardness and elastic modulus results obtained from depth versus load data are truly a giant leap compared to traditional hardness testers. This past century technology was based on visual inspection when accurate depth sensors were not available. Therefore, today there is absolutely no advantage with using outdated traditional hardness testers. The Micro Module is faster, easier, more accurate particularly at low loads and more repeatable. Testing can be performed on any material including very elastic material or on surfaces where identifying the indent is challenging. Not only providing hardness and elastic modulus but also a wide range of testing such as creep, stress-strain curves, yield strength, fatigue, fracture toughness, scratch and marring resistance, plastic/elastic deformation, wear rate and friction coefficient.

And for those using antiquated scratch testing instruments. These systems have a limited range of load and use cantilever load cells prone to side bending that can be seen in observing wavy scratches at high loads. Unlike the micro module that has been designed with a rigid compressive load cell and measures depth using a capacitor directly connected to the shaft holding the indenter. The result is the highest accuracy available on the market. The wide usable range of loads (5 orders of magnitude) of a single micro module makes it possible to do a high load scratch test, at up to 200N for a 5micron and up on a DLC, TiN, TiC coating, and then use a 50mN load to measure hardness and elastic modulus without the influence of the substrate. For thinner coatings down to sub microns, the 20N can be used in the same way with depth versus load down to the single digit mN but still do excellent scratch testing up to 20N. These more sensitive loads are ideal for the characterization of industrial coatings; ranging from plasma processed layers used in semiconductor and optical technology, to decorative and protective coatings used for automobile parts and consumer goods. Easy and fast to calibrate, the accuracy of the data through time and from one instrument to another is insured. High performance longevity with low maintenance cost and especially high accuracy comes standard.

MICRO TESTING MODES

Microindentation | Micro Hardness Testing