High Temperature Module

Temperature plays a critical role on the extent of wear damage to materials. The Tribometer conducts wear experiments at high temperatures up to 1000°C for the rotative and 900°C for the linear tests.

How does it work?

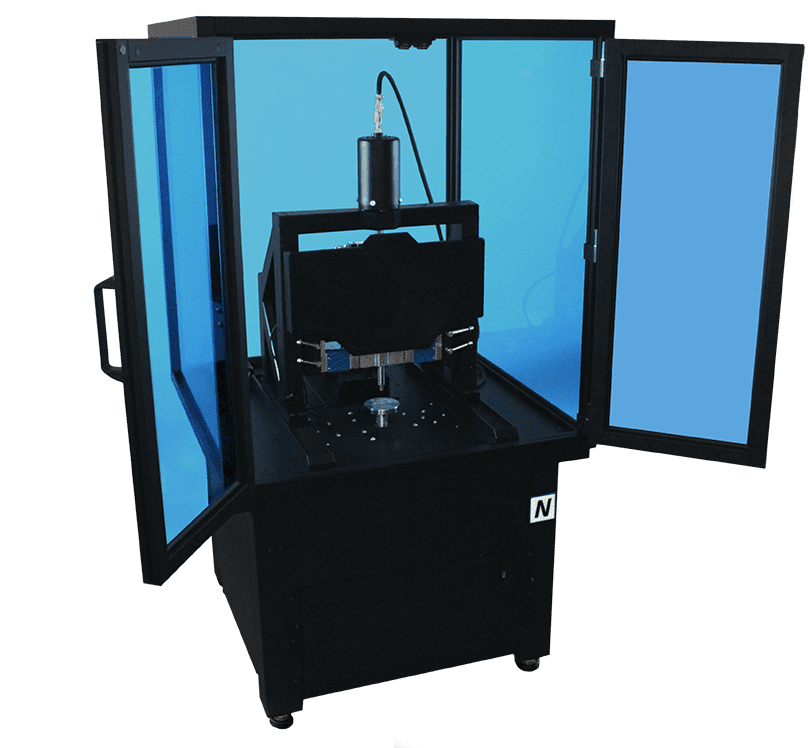

The contact of the wear process is totally enclosed in a removable large oven which ensures uniform and stable temperature surrounding the sample and the counter material.

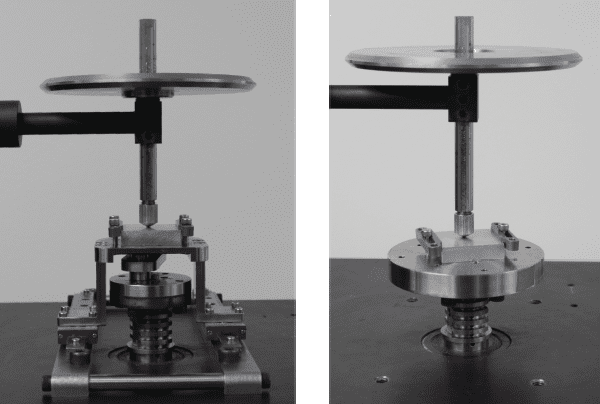

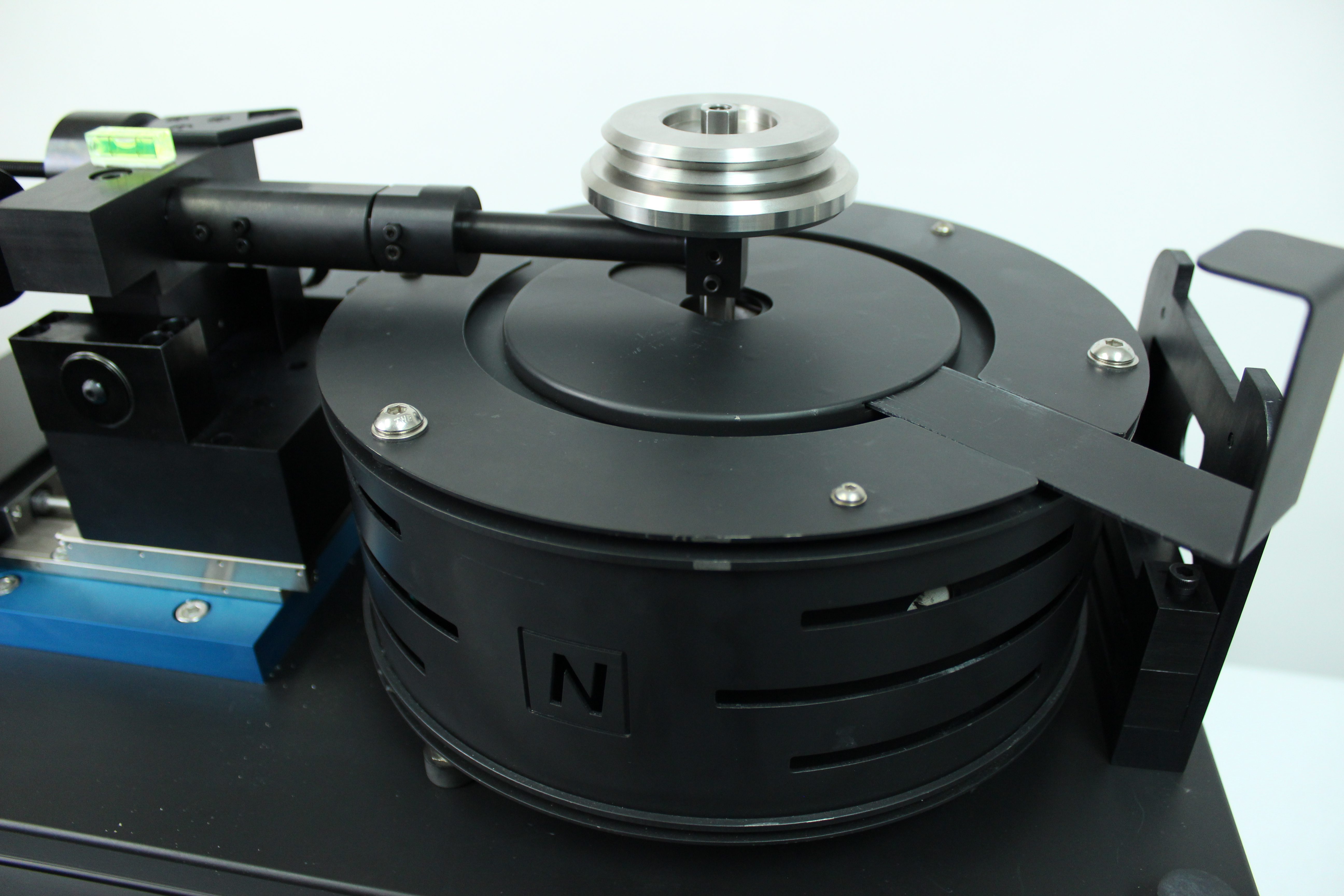

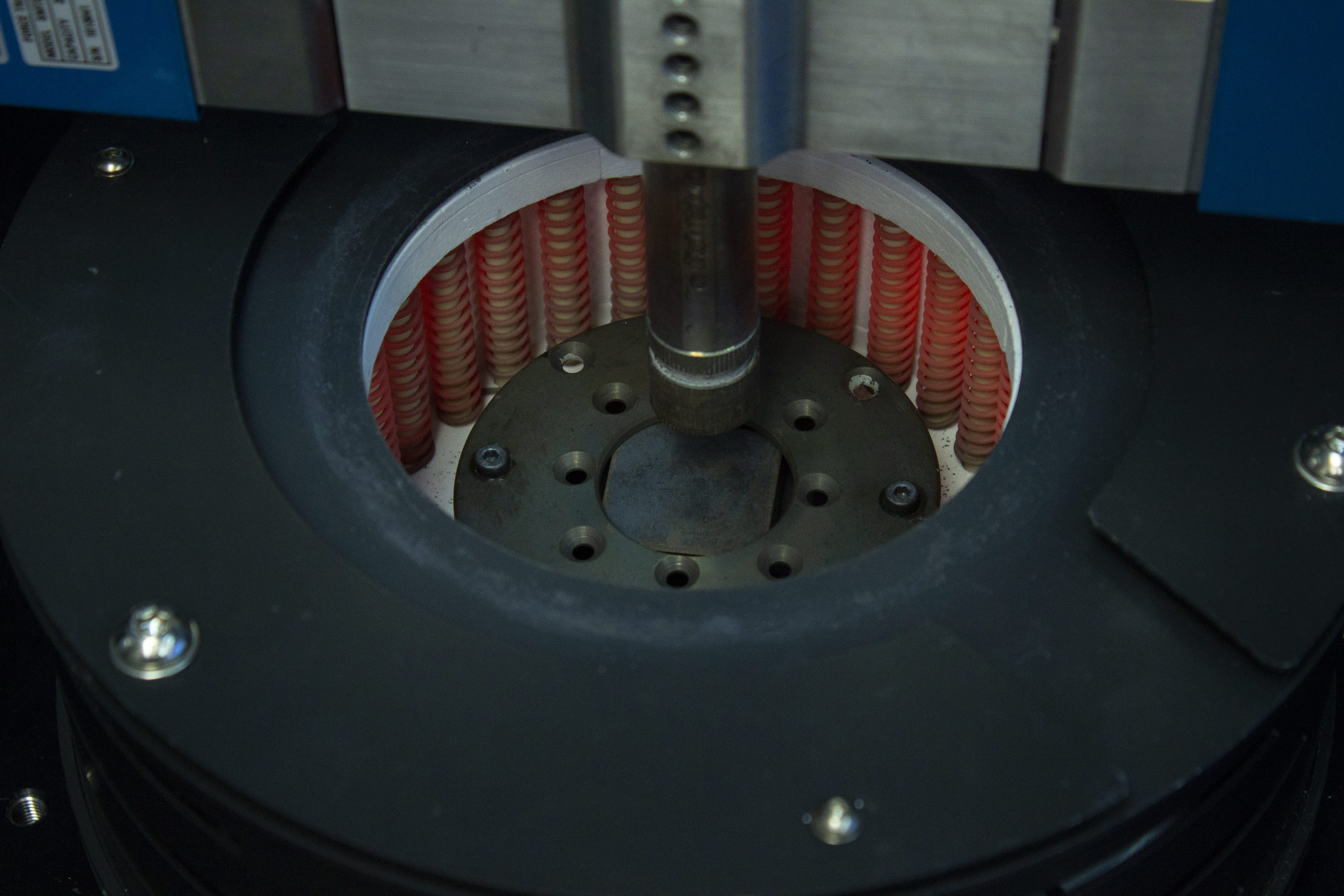

The thermocouple is either set up to be very close to the point of contact or directly touching the back on the ball inside the ball holder to achieve the best accuracy of the temperature reading. The unique heat sink design on the main shaft of the rotative motor makes air supply sufficient for cooling.

The load cell is self-calibrated for high temperatures to ensure accurate data.

Extreme Versatility

Modules

- Rotative

- Linear

- Scratch

- Ring-On-Ring

Properties Analyzed

- Temperature Wear & Friction Data

Environment

- Inert Gas feed in the oven