In-Line Profilometer

NANOVEA’s in-line profilometer solutions integrate non-contact chromatic light sensors directly into production lines, enabling real-time surface measurement and immediate process feedback.

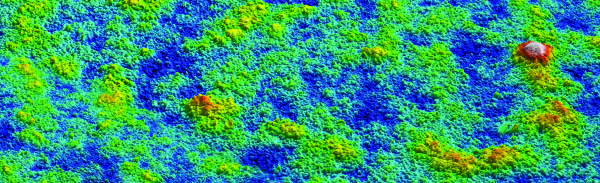

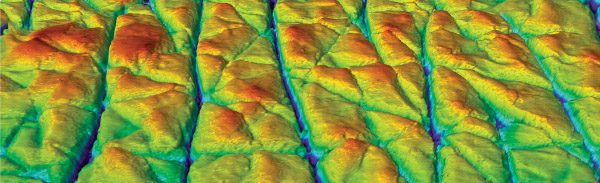

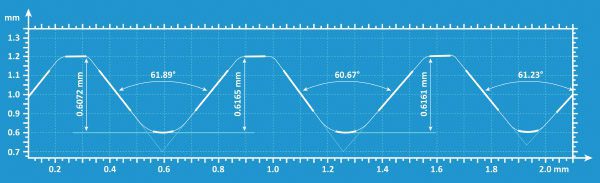

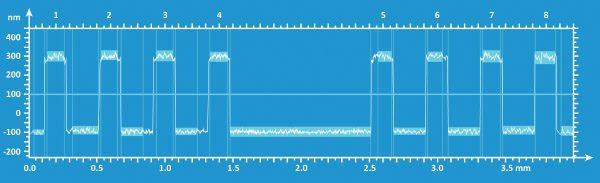

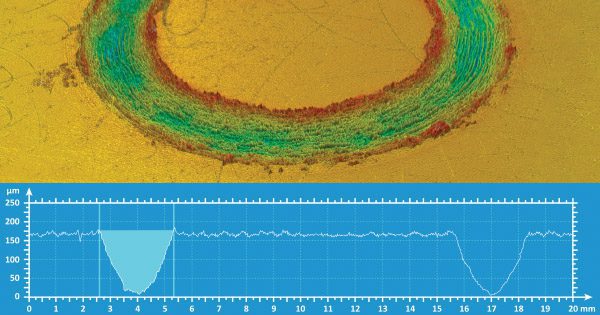

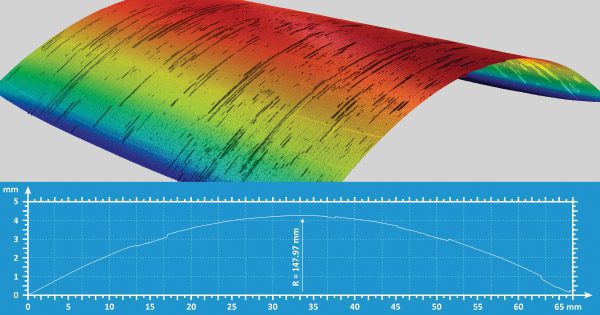

Built on the same proven sensors used in NANOVEA’s laboratory profilometers, these systems deliver accurate 2D and 3D surface characterization – roughness, texture, geometry, and defect detection – without interrupting production.

IN-SITU MEASUREMENT

& REAL-TIME FEEDBACK

NANOVEA’s unique software provides measurements and analysis of any surface in real time with acquisition rates of more than 1,300,000 points/sec.

One of its numerous features, Pass & Fail criteria specific to each sensor or average of all sensors, helps to effectively identify surface defects derived from materials processing and product manufacturing.

TRIGGERED

IN-LINE INSPECTION

CONTINUOUS

IN-LINE INSPECTION

2D & 3D NON-CONTACT PROFILOMETRY

HIGH QUALITY QUALITY CONTROL

SEAMLESS INTEGRATION

We provide personalized full integration support, including specific mounting structures so you don’t have to worry about disrupting your established process.