LIQUID TRIBOLOGY INTRO

Tribometer Instruments | Lab Services | Rotative | Linear | Application Notes

Liquid Tribology Process:

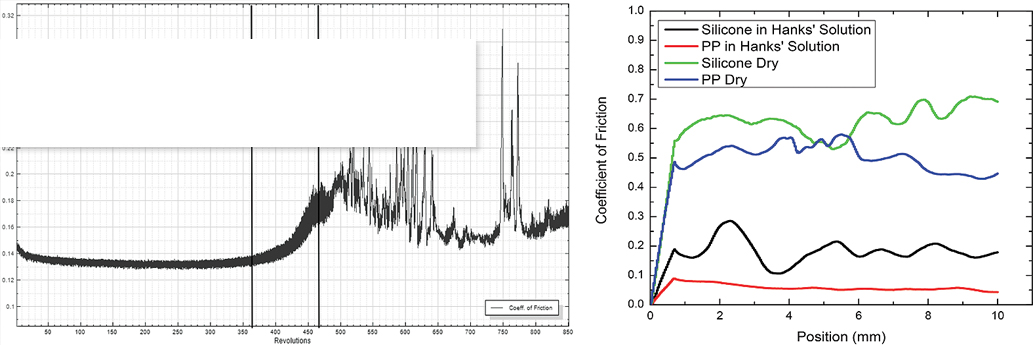

Nanovea Tribometer provides the liquid/lubricant linear and rotative cup modules to carry out wear and friction experiments in liquids or lubricants. Different liquid solutions can be used to simulate the wear process for realistic applications. The wear and friction of materials in liquids or lubricants is critical for various industrial applications. For example, the biomaterials for biological replacements such as joints, stents and dental roots, require excellent long term resistance and adequate strength in a liquid environment. The parts in the motor engines should be protected by proper lubrication to reduce wear and friction and to extend lifespan. During the wear test, the evolution of coefficient of friction provides insight in different stages of the wear development. Combining with the precise control of speed and continuous change of speed, a continual Stribeck Curve for the test lubricant can be measured. A liquid heating coil is available to heat the liquid in the cups up to 150°C. An accessory to the cup is the drop by drop lubrication option which allows lubrication test even at very fast rotation speed of 5000rpm.

Standards:

• ASTM G99

• ASTM G133

Properties Analyzed During Liquid Wear:

• Wear Rates

• Coefficient of Friction

• Friction versus speed

• Stribeck Curve

• Coefficient of friction or wear versus temperature

Software Controls During Liquid Wear:

• Variable Speed Control during Test

Environment Controls During Liquid Wear:

• Various Solutions to Simulate Realistic Applications

Tips: (Steel, Diamond, WC, Al2O3 and many other materials):

• 3, 6, 10 and 25mm ball

• Custom ball sizes

• Custom Pins

• Flat Plate

• Custom geometries

Sample(s) Holders:

• Standard Clamp

• Clip Mounting on Liquid Cup

• Other Sample Holders available for varied geometries

Additional Tribology Testing:

Temperature

Corrosion