Categoría: Notas de aplicación

Morfología in situ a alta temperatura mediante perfilometría 3D

Las altas temperaturas pueden alterar la textura superficial, la rugosidad y las formas de los materiales, lo que puede provocar un mal funcionamiento de los dispositivos y fallos mecánicos. Para garantizar la calidad de los materiales o dispositivos utilizados a temperaturas elevadas, es necesario disponer de datos precisos y fiables. in situ La monitorización morfológica de la evolución de la forma a altas temperaturas es necesaria para comprender mejor el mecanismo de deformación del material. Además, la monitorización en tiempo real de la morfología superficial a altas temperaturas es muy útil en el procesamiento de materiales, como el mecanizado por láser. Los perfilómetros sin contacto Nanovea 3D miden la morfología superficial de los materiales sin tocar la muestra, evitando introducir arañazos adicionales o alteraciones de la forma que pueden provocar tecnologías de contacto como el palpador deslizante. Su capacidad de medición sin contacto también permite medir la forma de muestras fundidas.

Efecto de la textura de la superficie de aluminio anodizado en el brillo

El anodizado es un proceso de pasivación electrolítica que se aplica habitualmente para convertir el aluminio en óxido de aluminio. Puede modificar el textura de la superficie y cambia la microestructura del metal cerca de la superficie. Esta capa de óxido de aluminio anodizado suele ser mucho más resistente y adherente que la mayoría de los tipos de pintura y chapado metálico. Puede aumentar significativamente la resistencia a la corrosión y al desgaste y mejorar los efectos cosméticos de los productos. El aluminio anodizado se utiliza mucho en dispositivos electrónicos y productos de consumo, como teléfonos móviles, cámaras, reproductores mp3 y muchos otros.

Efecto de la textura de la superficie de aluminio anodizado en el brillo

Adhesión del revestimiento de oro sobre sustrato de cristal de cuarzo

Como dispositivo extremadamente preciso, la microbalanza de cristal de cuarzo (QCM) mide el cambio de masa hasta 0,1 nanogramos. Cualquier pérdida de masa o delaminación de los electrodos en la placa de cuarzo será detectada por el cristal de cuarzo y causará errores de medición significativos. En consecuencia, la calidad intrínseca del recubrimiento de oro de los electrodos y la integridad interfacial del sistema de recubrimiento/sustrato desempeñan un papel esencial en la realización de mediciones de masa precisas y repetibles. El sitio Prueba de microarañazos es una medida comparativa ampliamente utilizada para evaluar las propiedades relativas de cohesión o adherencia de los revestimientos basada en la comparación de las cargas críticas a las que aparecen los fallos. Es una herramienta superior para el control fiable de la calidad de los QCM.

Adhesión del revestimiento de oro sobre sustrato de cristal de cuarzo

Acabado superficial de la microbalanza de cristal de cuarzo

Un control de calidad fiable depende en gran medida de una inspección de superficies precisa, cuantificable y reproducible. La planitud y el acabado de la superficie de la microbalanza de cristal de cuarzo (QCM) son vitales para su precisión, y ambas mediciones en 3D garantizan un procesamiento de fabricación y unas medidas de control adecuados. A diferencia de la técnica de sonda de contacto, el sistema Nanovea Perfilómetro realiza una medición de la superficie de la muestra en 3D sin contacto. Esto elimina el riesgo de crear microarañazos en la superficie del QCM que puedan causar imprecisiones o errores en la medición de la masa.

Tribología del recubrimiento de oro sobre sustrato de cristal de cuarzo

El QCM funciona basándose en las propiedades piezoeléctricas del cristal de cuarzo. Mide el cambio de masa en la superficie hasta 0,1 nanogramos durante la deposición de material detectando las variaciones en la frecuencia de resonancia del cristal. Debido a las características de extrema sensibilidad y precisión del QCM, es fundamental garantizar que los dos electrodos situados a ambos lados de la placa de cuarzo posean una buena resistencia al desgaste. Cualquier pérdida de masa en los electrodos metálicos causada por el desgaste puede provocar un error significativo en la medición. Por lo tanto, una evaluación fiable y precisa del desgaste utilizando un Tribómetro es importante para el control de calidad y la I+D de QCM.

Tribología del recubrimiento de oro sobre sustrato de cristal de cuarzo

Topografía 3D con superposición de imágenes de PCB

El diseño electrónico más sofisticado y la disposición de chips semiconductores, circuitos y sistemas requieren una fabricación de alta precisión y un control de calidad superior. A diferencia de otras técnicas como las sondas táctiles o la interferometría, el Nanovea 3D Non-Contact Perfilómetromediante cromatismo axial, puede medir prácticamente cualquier superficie de material. Durante la medición del perfil de la superficie se obtiene un rango de nano a macro con una influencia nula de la reflectividad de la muestra, la absorción y los ángulos de superficie elevados. Esto es ideal para la inspección de la superficie del conjunto de placas de circuito impreso (PCBA), que contiene una variedad de componentes electrónicos de diferentes materiales, reflectividad y características finas. Además, la técnica de perfilado sin contacto mide las características de la superficie sin tocar el PCBA, evitando el riesgo de dañar los delicados circuitos y componentes electrónicos debido al deslizamiento del palpador de la sonda. La combinación de alta precisión, alta velocidad, ausencia de contacto y facilidad de uso convierte al perfilómetro Nanovea en una herramienta ideal para la inspección de PCBA.

Fallo del revestimiento de alambre de cobre mediante tribología

La calidad de la superficie del alambre de cobre es fundamental para su rendimiento y vida útil. Los microdefectos en la superficie del alambre pueden provocar un desgaste excesivo, el inicio y la propagación de grietas y una soldabilidad inadecuada. Un tratamiento adecuado de la superficie puede eliminar los defectos superficiales que se generan durante el trefilado y mejorar la resistencia a la corrosión, el desgaste y los arañazos del alambre de cobre. Muchas aplicaciones, como la industria aeroespacial y los aviones comerciales, requieren que los hilos de cobre se comporten de forma controlada para evitar fallos inesperados en los equipos. Se necesitan mediciones cuantificables y fiables para evaluar cuantitativamente la resistencia al desgaste y al rayado de la superficie del alambre de cobre.

Resistencia al desgaste y a los arañazos del alambre de cobre

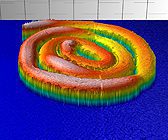

Herramienta de cartografía de propiedades mecánicas Broadview

Arriba se muestra un ejemplo de la herramienta de selección de mapas de visión amplia de Nanovea, pendiente de patente. Esta nueva herramienta permite a los usuarios seleccionar fácilmente cualquier ubicación en una amplia vista de la superficie de la muestra. Además, el usuario puede seleccionar todos los parámetros de prueba en cada ubicación, ya sea para una prueba o para un mapeo de varias pruebas. Todas las ubicaciones y parámetros de ensayo pueden guardarse en recetas fácilmente recuperables. Este importante avance permite realizar estudios de propiedades mecánicas desde nanométricas hasta macromecánicas de forma rápida y sencilla. Obtenga más información en la nota de aplicación de este mes: Cartografía de propiedades mecánicas

Dureza y módulo elástico de la madera mediante microindentación

Dureza y módulo elástico de la madera mediante microindentación