Categoría: Notas de aplicación

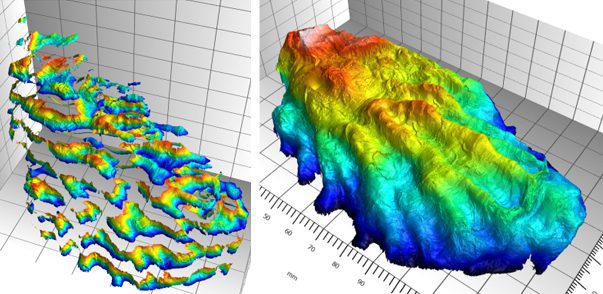

Conchology Topography Measurement Using 3D Profilometry

Conchology topography, by scanning the whole surface of an oyster shell, the Nanovea HS2000 Line Sensor will display its ability to work with large samples with abnormal geometries. Reflectivity, transparency, and angles do not affect the data collected with our technology, making 3D Non-Contact Perfilometría ideal for all types of samples. Another difficulty that lies with profiling an oyster shell lies in its lack of flat base. Samples typically needs to be securely mounted to the stage to minimize wobbling as the stage move. This usually requires additional sample preparation or fixtures to be used. The smooth air bearing stages on the Nanovea HS2000 Line Sensor, however, drastically minimizes stage noise. Its motorized control of the x, y, and z stages also allows for ease in extending varying height measurement. The extended measurement shown in this study, allows our instrument to capture a full surface that is beyond its pen height range limits (approximately 4mm).

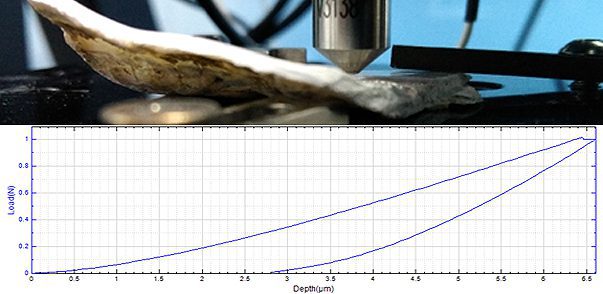

Propiedades biológico-mecánicas de la concha de ostra

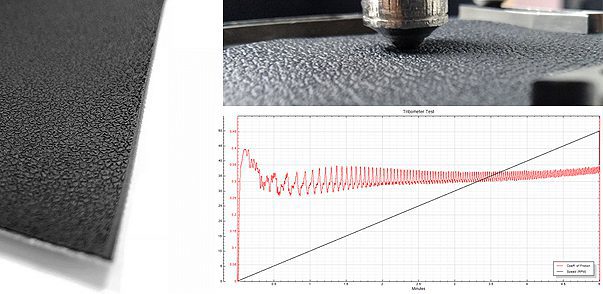

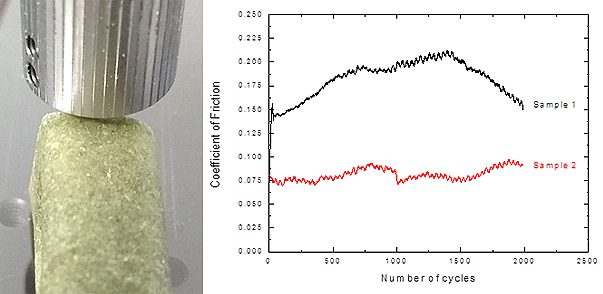

Leather Coefficient of friction Using Tribometer

Leather friction (COF) is quite important for leather since it can be used to characterize properties such as slip resistance, finish and material degradation. For leather used in footwear, the slip resistance must be sufficiently high. Slip resistance can be characterized by observing the static COF and dynamic COF with a Tribómetro. COF also determines how much friction is produced when rubbing between two surfaces occur. This can be used to determine the aesthetic quality and durability of the leather finish when applied to clothing, tooling, and upholstery.

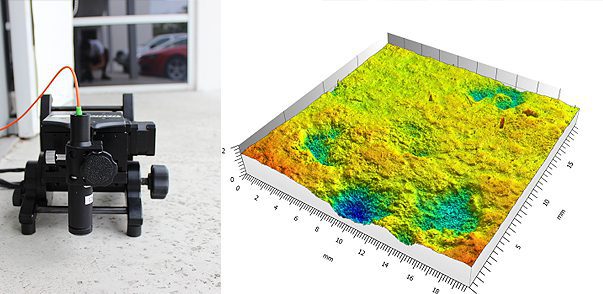

Concrete Roughness Using Portable 3D Profilometry

Measurement of nonconventional samples is difficult mainly due to problems mounting the sample onto a stage. For Nanovea’s JR25, the sample does not need to be mounted; it just has to remain unmoving. This means large objects such as walls, cars, or machines can be easily scanned. Its compact size makes it portable as well as diverse. It can tilt its pen sensor at an angle which makes it ideal in measuring samples that are not flat and have difficulties exposing its area of interest to a scanning probe. Since the 3D Non-Contact Perfilómetro uses axial chromatism technology, it can also measure any surface with minimal sample preparation. Nano to macro heights can be measured with zero influence from sample reflectivity, transparency, and curvature. The flexibility and portability of Nanovea JR25 3D Non-Contact Profilometer makes measuring a larger range of samples simpler than compared to conventional profilometers.

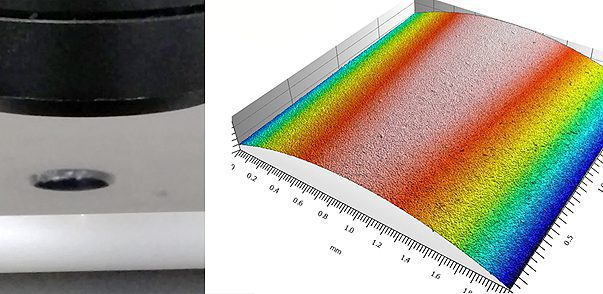

Polymeric Tube Finish and Dimension

Tubes made from polymeric material are commonly used in many industries ranging from automotive, medical, electrical, to many other categories. In this study, medical catheters made of different polymeric materials were studied using the Nanovea 3D Non-Contact Perfilómetro para medir la rugosidad, la morfología y las dimensiones de la superficie. La rugosidad de la superficie es crucial para los catéteres, ya que muchos de sus problemas, como las infecciones, los traumatismos físicos y las inflamaciones, pueden estar relacionados con la superficie del catéter. Las propiedades mecánicas, como el coeficiente de fricción, también pueden estudiarse observando las propiedades de la superficie. Estos datos cuantificables pueden obtenerse para garantizar que el catéter pueda utilizarse en aplicaciones médicas.

Propiedades mecánicas de los recubrimientos de obleas de carburo de silicio

Comprender las propiedades mecánicas de los recubrimientos de obleas de carburo de silicio es fundamental. El proceso de fabricación de dispositivos microelectrónicos puede tener más de 300 pasos de procesamiento diferentes y puede durar entre seis y ocho semanas. Durante este proceso, el sustrato de la oblea debe ser capaz de soportar las condiciones extremas de fabricación, ya que un fallo en cualquier paso supondría la pérdida de tiempo y dinero. Las pruebas de durezaPara garantizar que no se produzca ningún fallo, la resistencia a la adherencia/arañazos y la tasa de desgaste/COF de la oblea deben cumplir ciertos requisitos para sobrevivir a las condiciones impuestas durante el proceso de fabricación y aplicación.

Propiedades mecánicas de los recubrimientos de obleas de carburo de silicio

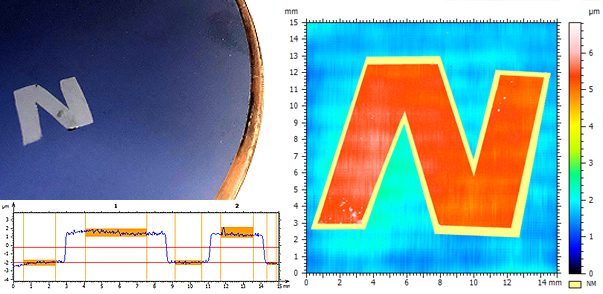

Wafer Coating Thickness Measurement Using 3D Profilometry

Wafer Coating Thickness Measurement is critical. Silicon wafers are widely used in the making of integrated circuits and other micro devices used in a vast number of industries. A constant demand for thinner and smoother wafers and wafer coatings makes the Nanovea 3D non-contact Perfilómetro a great tool to quantify coating thickness and roughness of just about any surface. The measurements in this article were taken from a coated wafer sample in order to demonstrate the capabilities of our 3D Non-Contact Profilometer.

Estudio tribológico de la fricción de las golosinas dentales para perros

Las golosinas dentales con sabor han demostrado ser un método eficaz, cómodo y fácil de usar para la limpieza dental canina. Las sabrosas y masticables golosinas dentales convierten la limpieza de dientes y encías en un procedimiento agradable. Durante las acciones mecánicas de masticación, la golosina dental crea fricción contra la superficie de los dientes para eliminar el sarro y las películas de bacterias. Se necesita un estudio tribológico fiable para comparar cuantitativamente la eficacia de las golosinas dentales para perros con diferentes texturas y rugosidades de superficie, y para proporcionar una visión de la correlación de la rugosidad de la superficie, la textura y la fricción para facilitar la I+D y el control de calidad de la producción de golosinas dentales.

Medición de la planitud de la pantalla mediante perfilometría 3D rápida

Medición de la planitud es una importante cualidad geométrica de la superficie en la fabricación de piezas y conjuntos de precisión. La planitud de la superficie desempeña un papel vital en el uso final del producto. Por ejemplo, las piezas que se conectan de forma estanca al aire o a los líquidos a través de una superficie requieren unas condiciones superficiales estrictas de planitud superior en la cara de contacto. La planitud de la pantalla es fundamental para la funcionalidad y la estética de dispositivos electrónicos como teléfonos móviles, tabletas y ordenadores portátiles. Cualquier imperfección en la planitud de la pantalla puede crear una impresión y una experiencia negativas del producto para el usuario.

Véase Videoclip o Leer informe: Medición de la planitud de la pantalla mediante perfilometría 3D rápida

Cartografía de microindentación en vidrio

La cartografía de microindentación ha demostrado ser una herramienta fundamental para los estudios relacionados con la mecánica de superficies. La fractura se ha evaluado normalmente midiendo la dimensión de las grietas de la indentación, y el uso de la emisión acústica durante los ensayos ha sido una herramienta valiosa que se ha pasado por alto. Microindentación con la medición de Emisiones Acústicas (AE) proporciona un método fiable y fácil de usar para rastrear el comportamiento y la intensidad de la fractura durante el proceso de carga y descarga.