Categoría: Perfilometría | Altura y espesor de los escalones

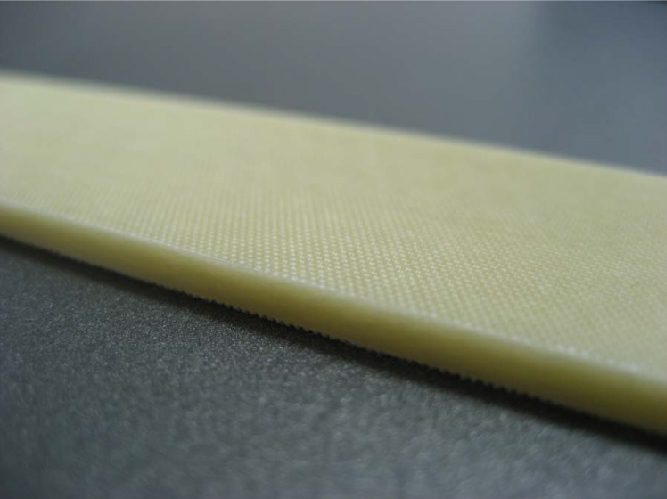

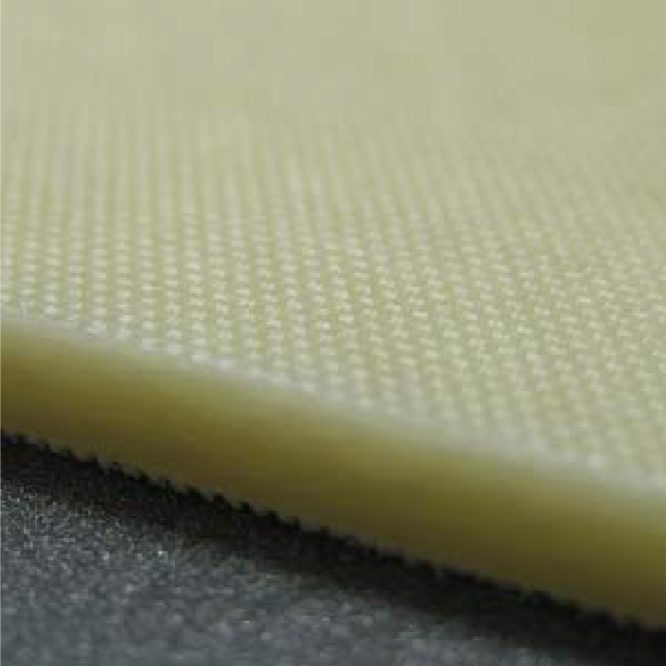

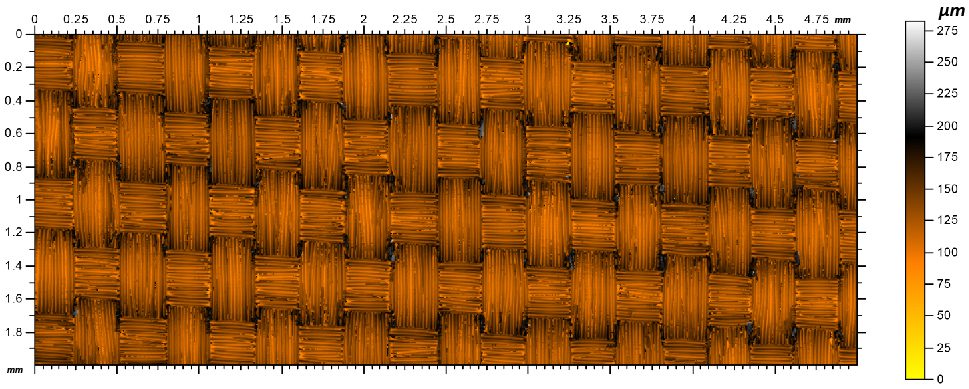

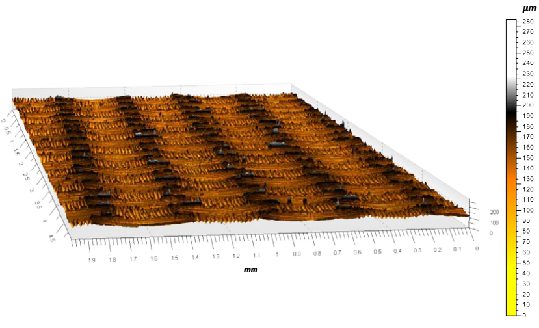

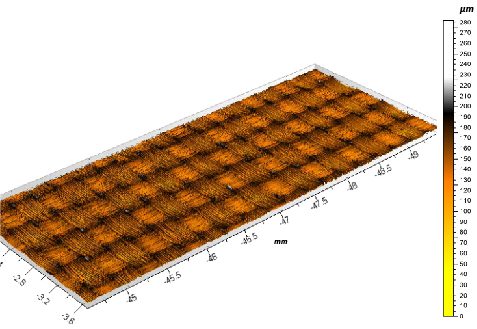

Topografía de superficies de fibra de vidrio mediante perfilometría 3D

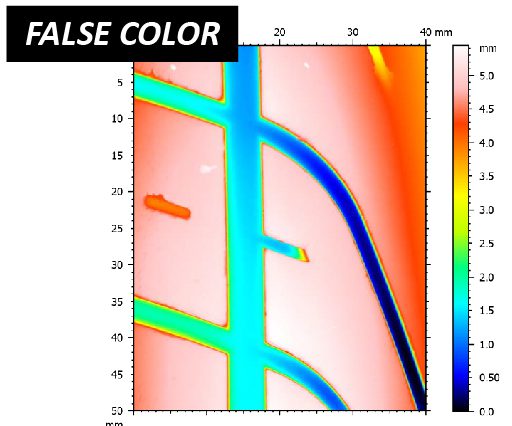

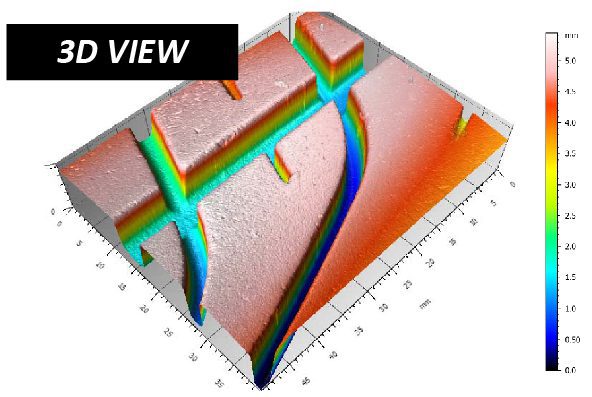

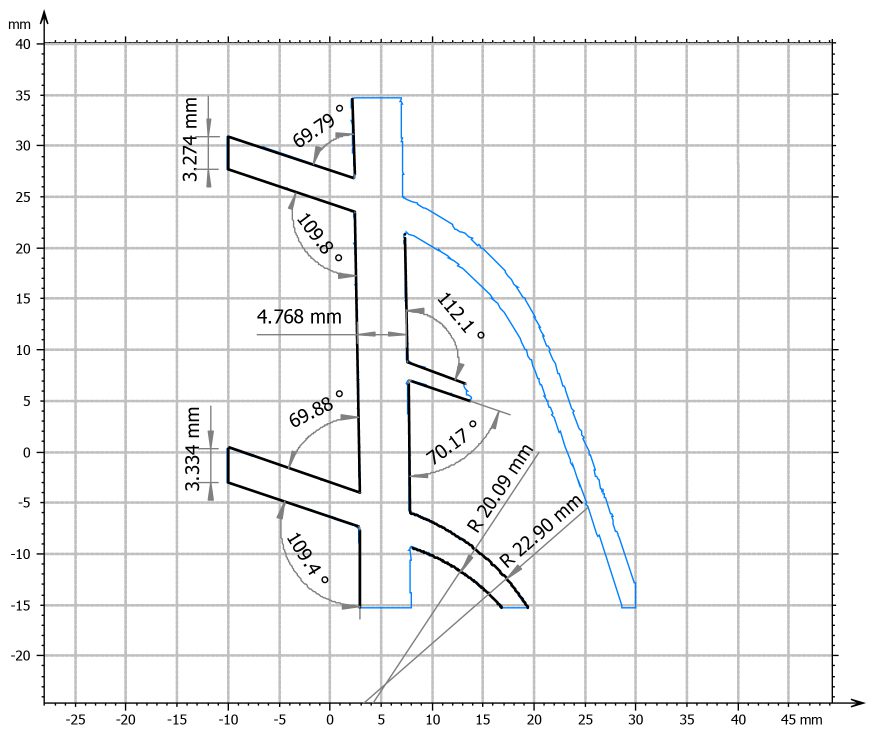

Medición de la profundidad del dibujo de los neumáticos y la rugosidad de la superficie de la goma | Perfilómetro óptico 3D

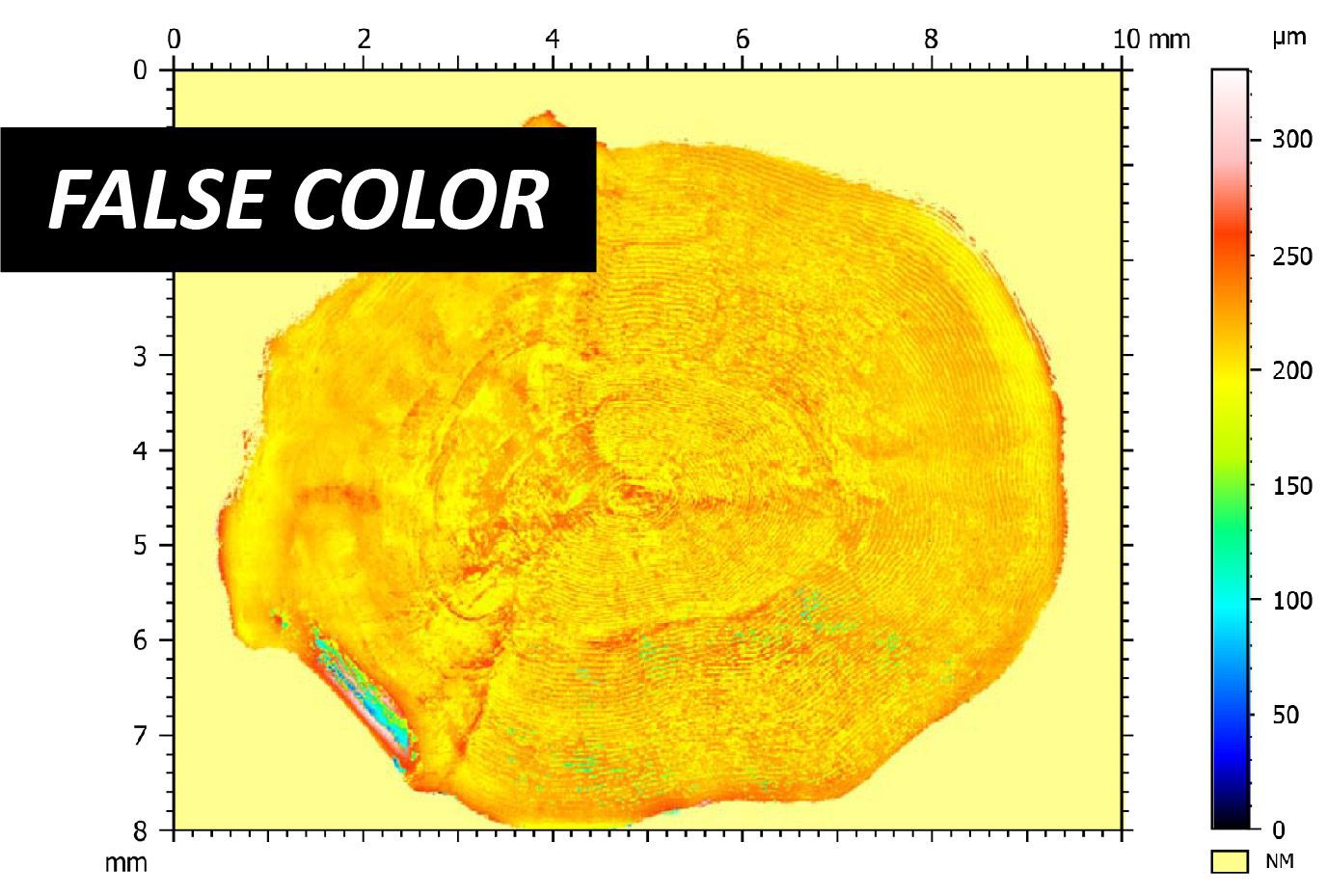

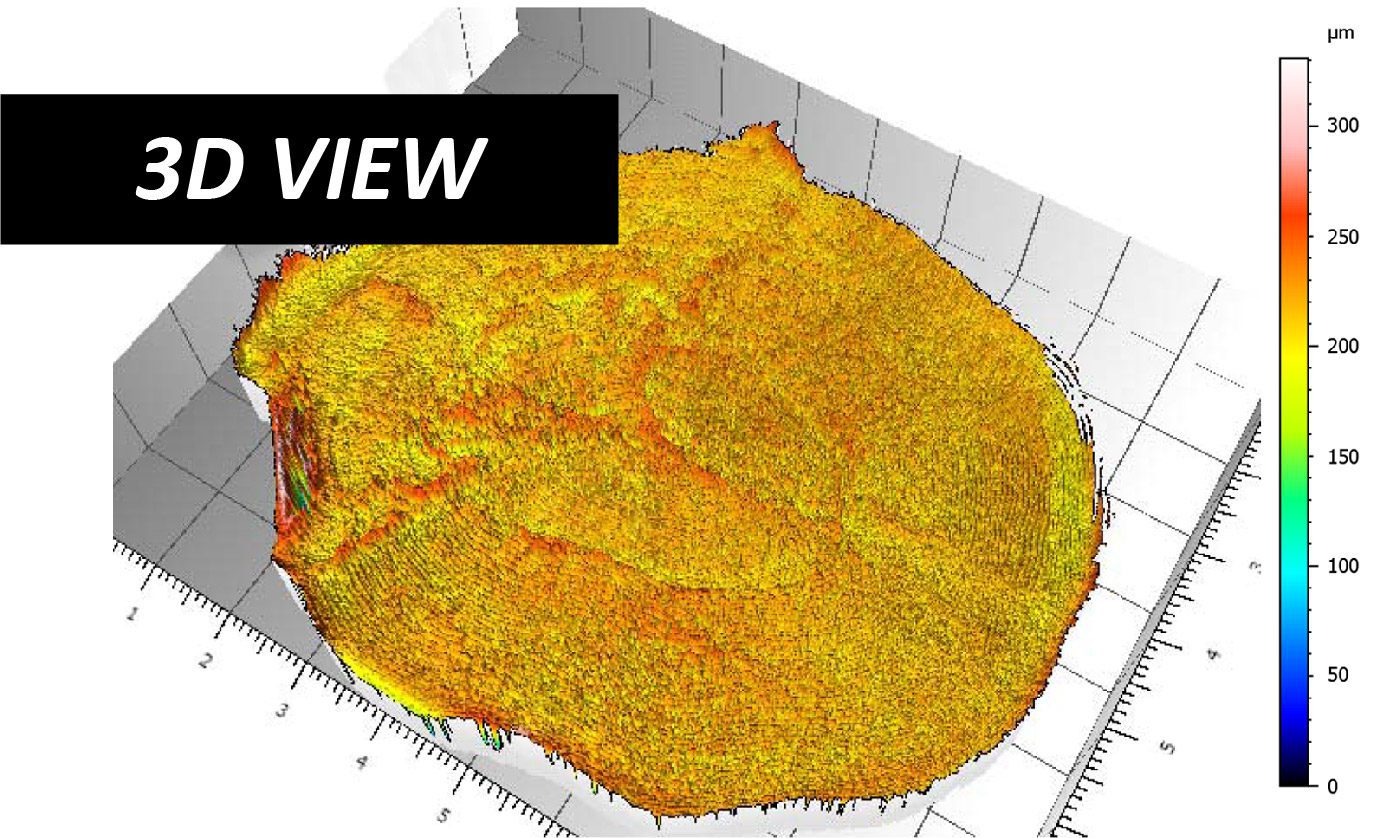

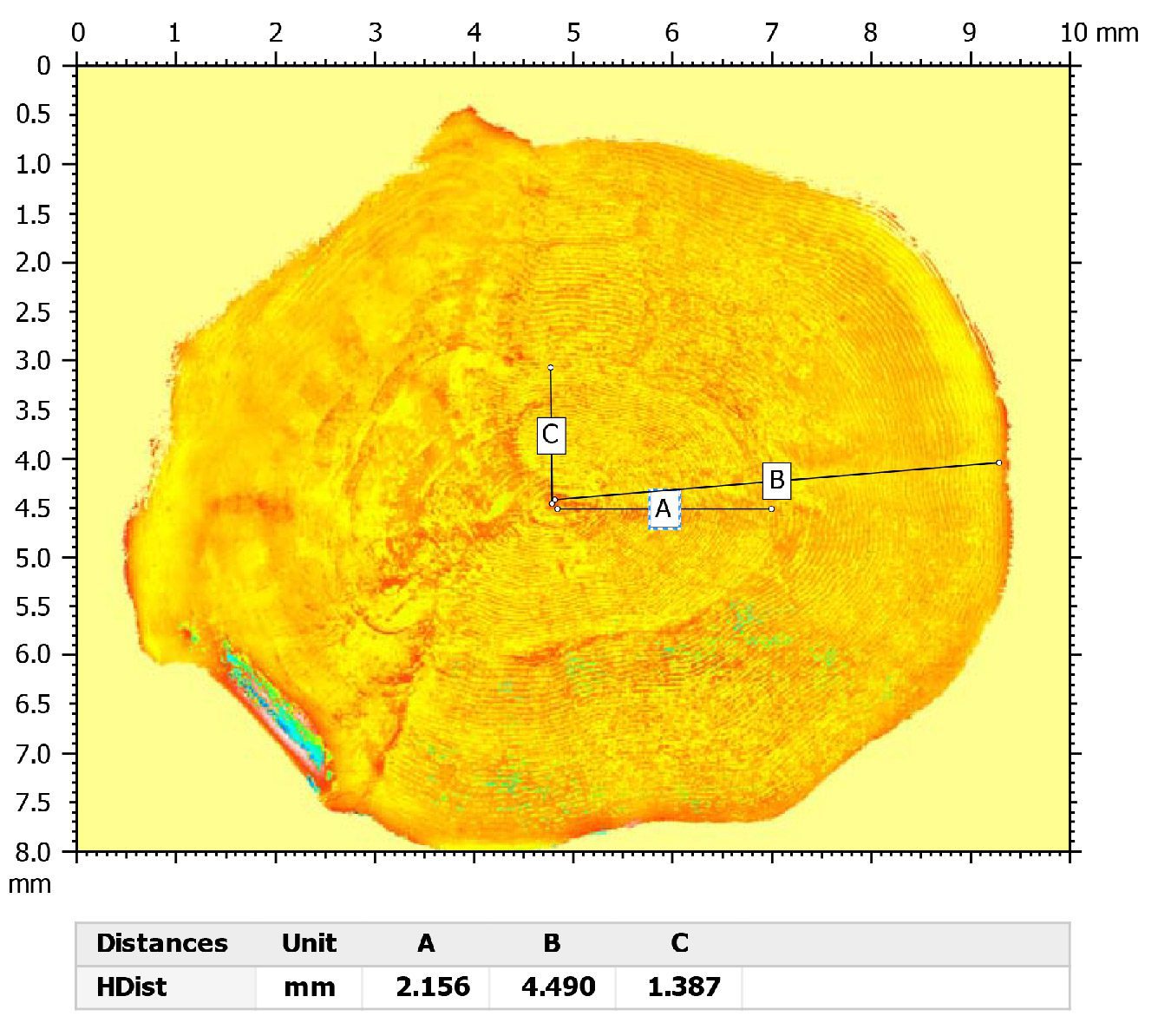

Análisis de la superficie de escamas de pez mediante un perfilómetro óptico 3D

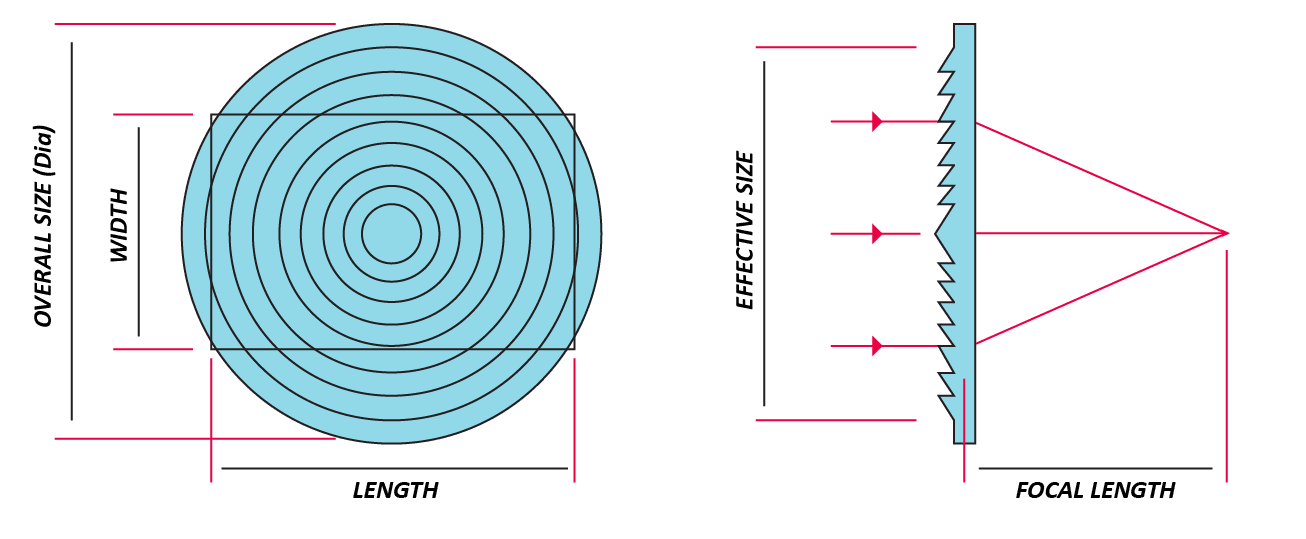

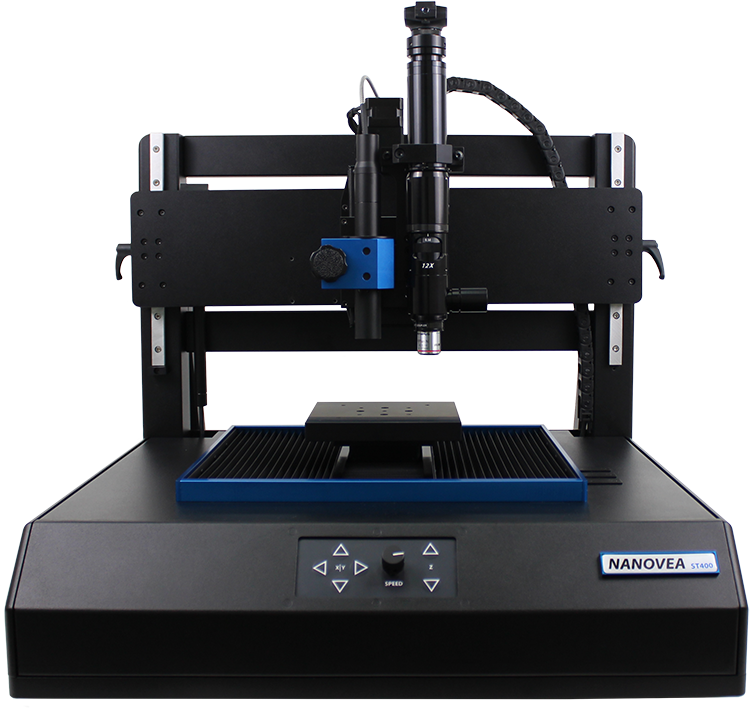

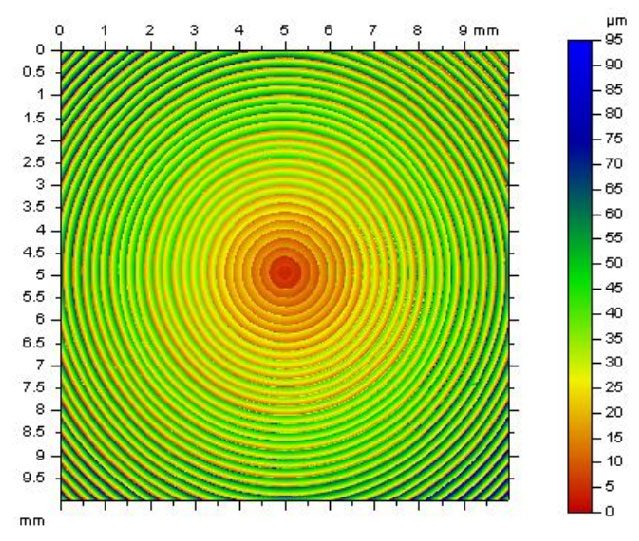

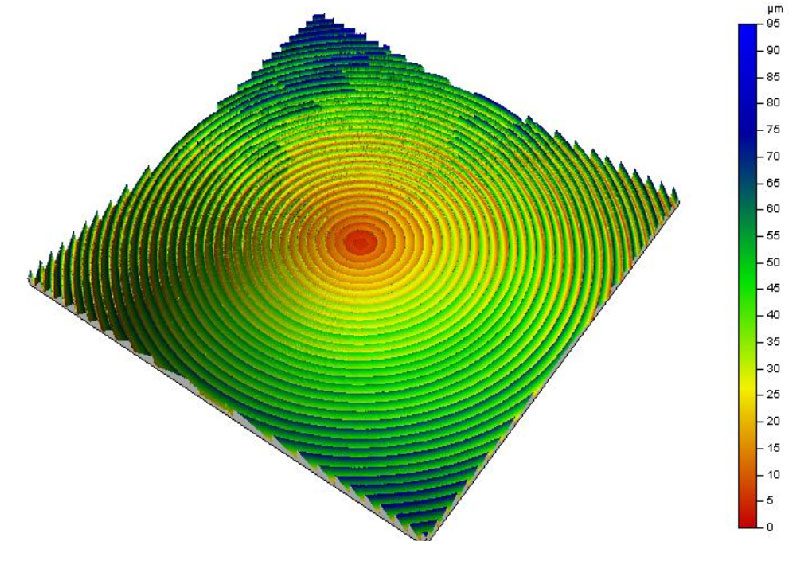

Topografía de la lente Fresnel

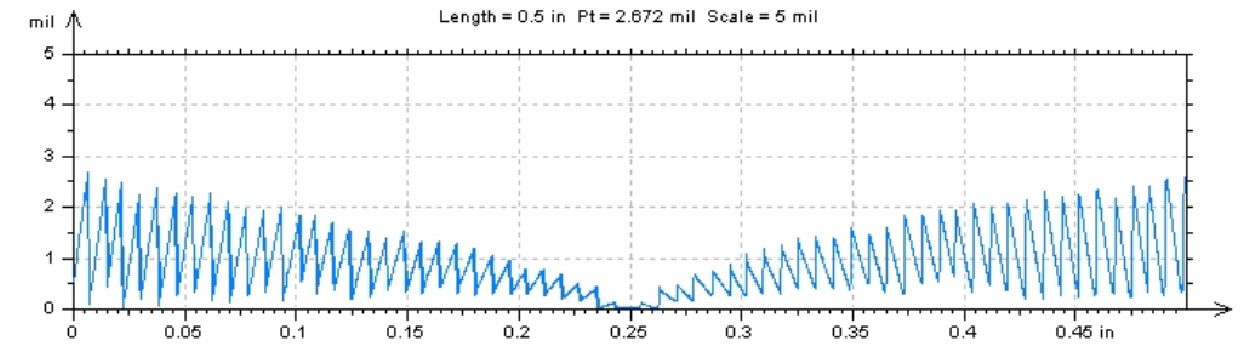

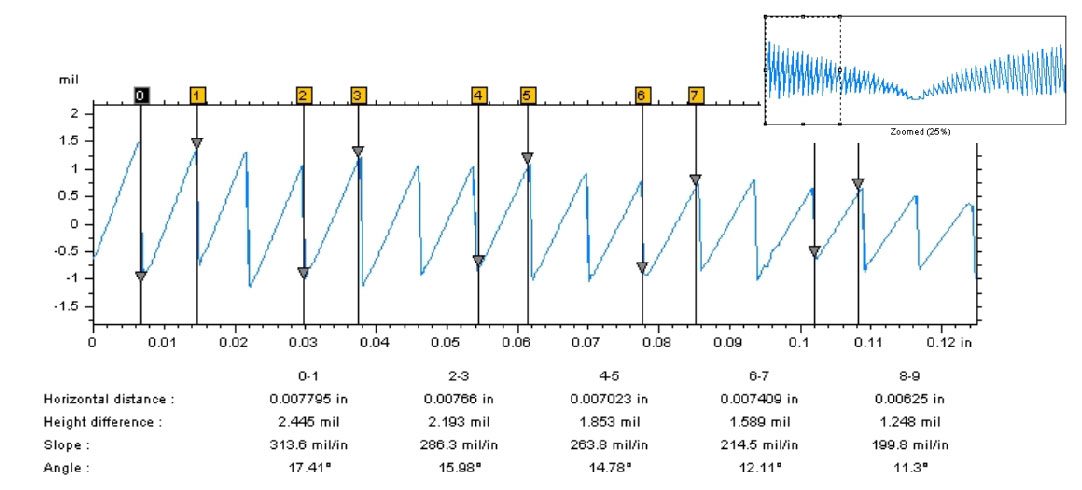

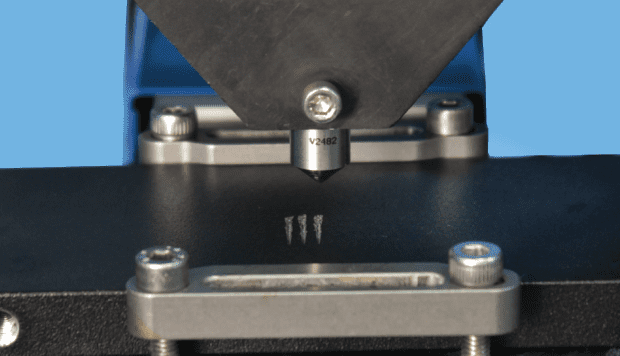

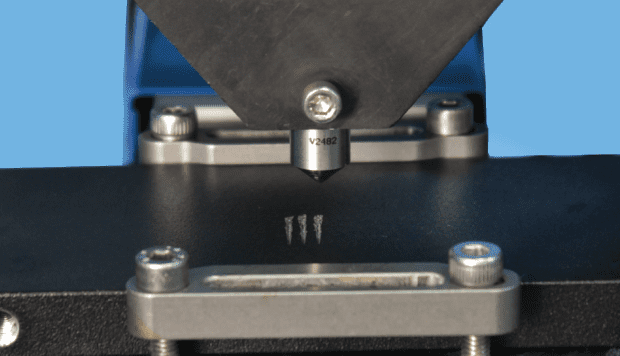

Comprensión de los fallos en los recubrimientos mediante pruebas de rayado

Introducción:

La ingeniería de superficies de los materiales desempeña un papel importante en diversas aplicaciones funcionales, que van desde la apariencia decorativa hasta la protección de los sustratos contra el desgaste, la corrosión y otras formas de agresión. Un factor importante y determinante que influye en la calidad y la vida útil de los recubrimientos es su fuerza cohesiva y adhesiva.

¡Haga clic aquí para leer!

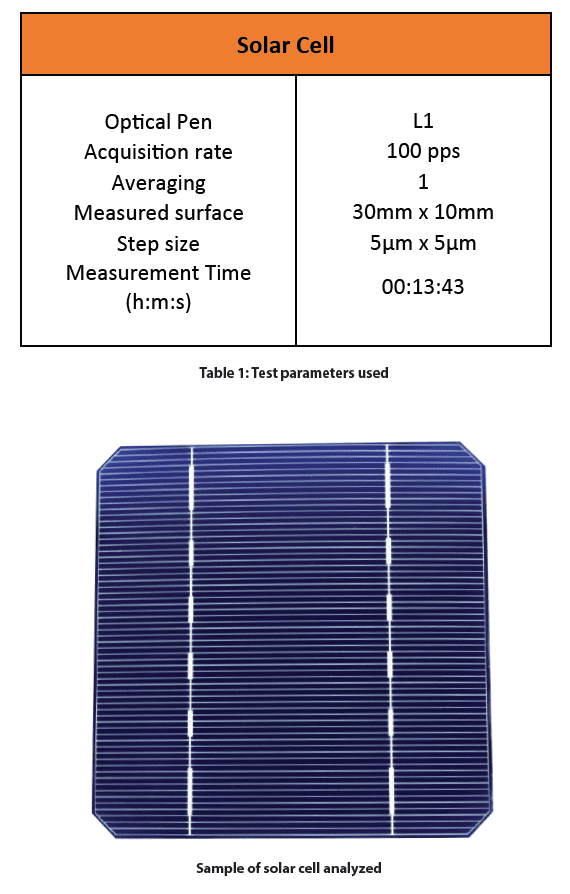

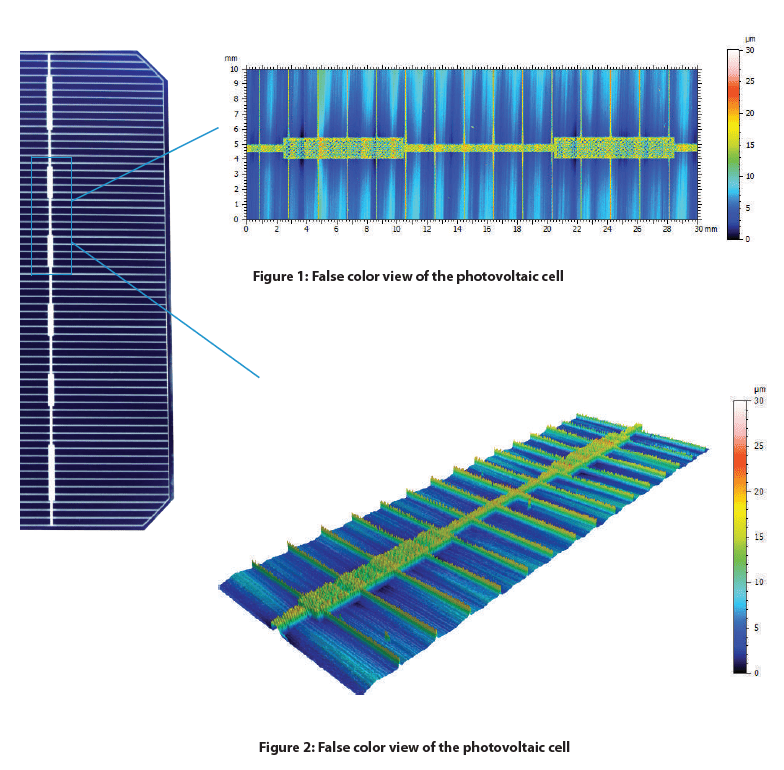

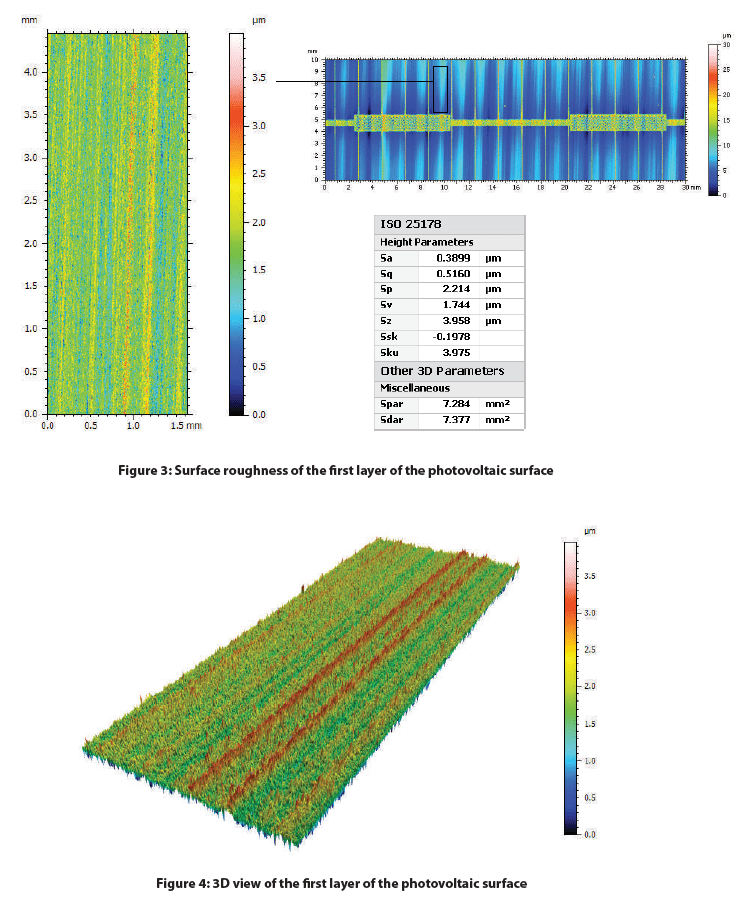

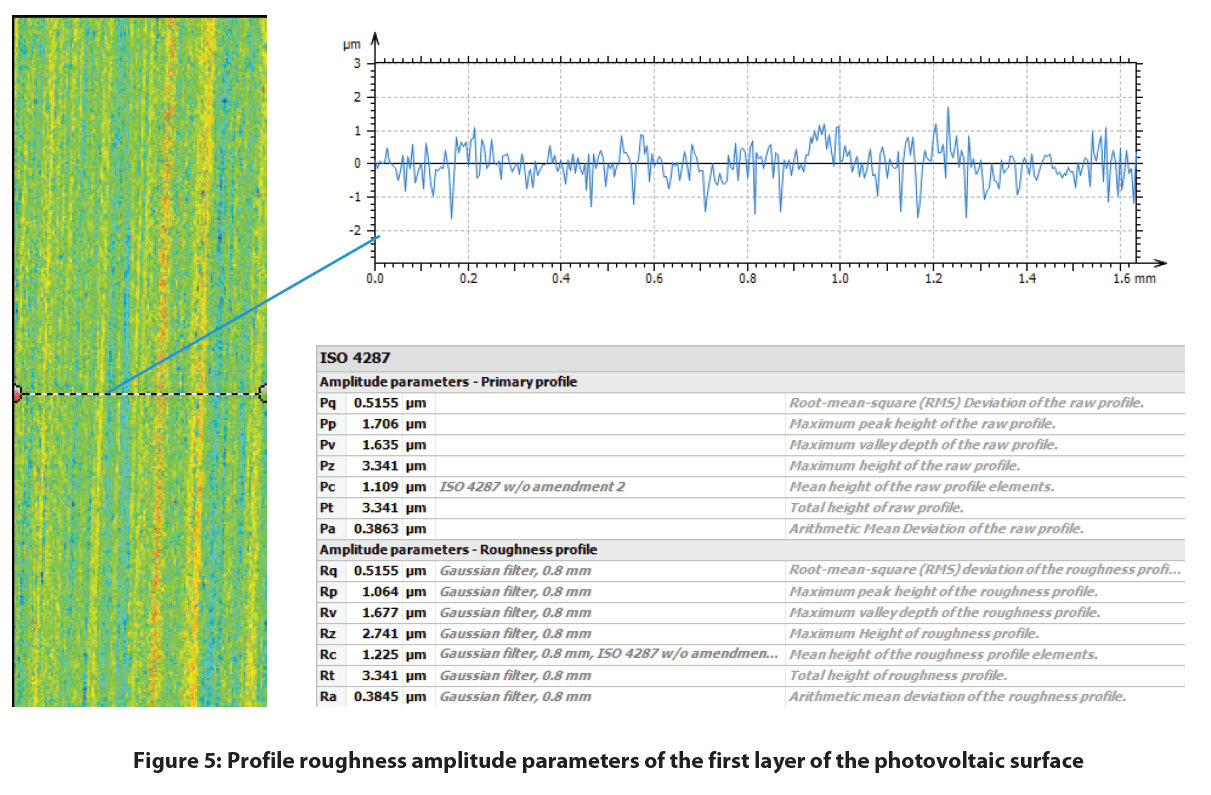

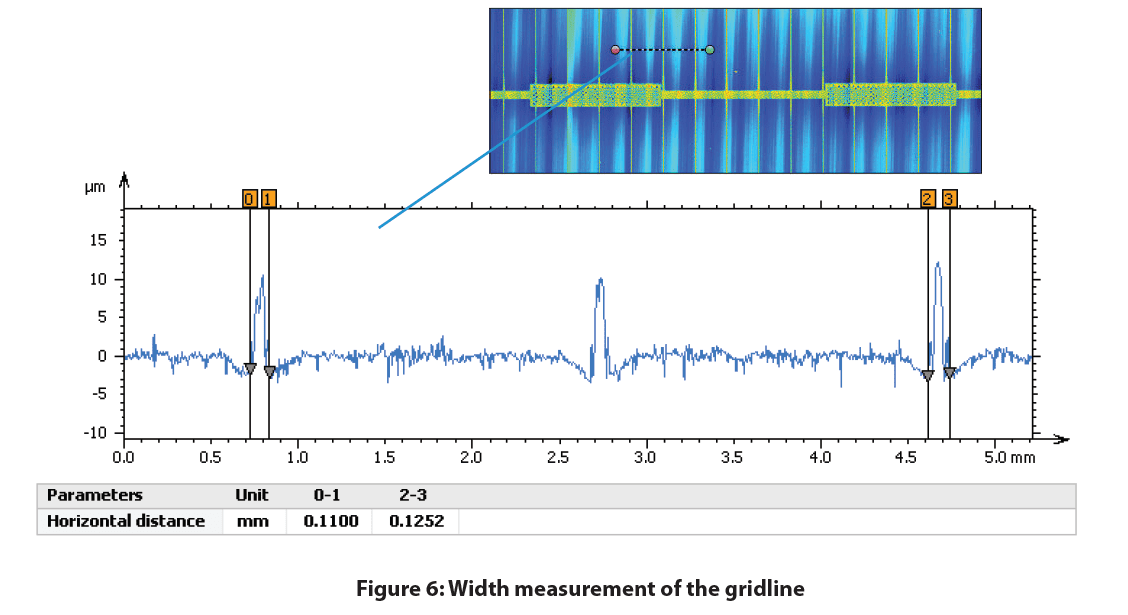

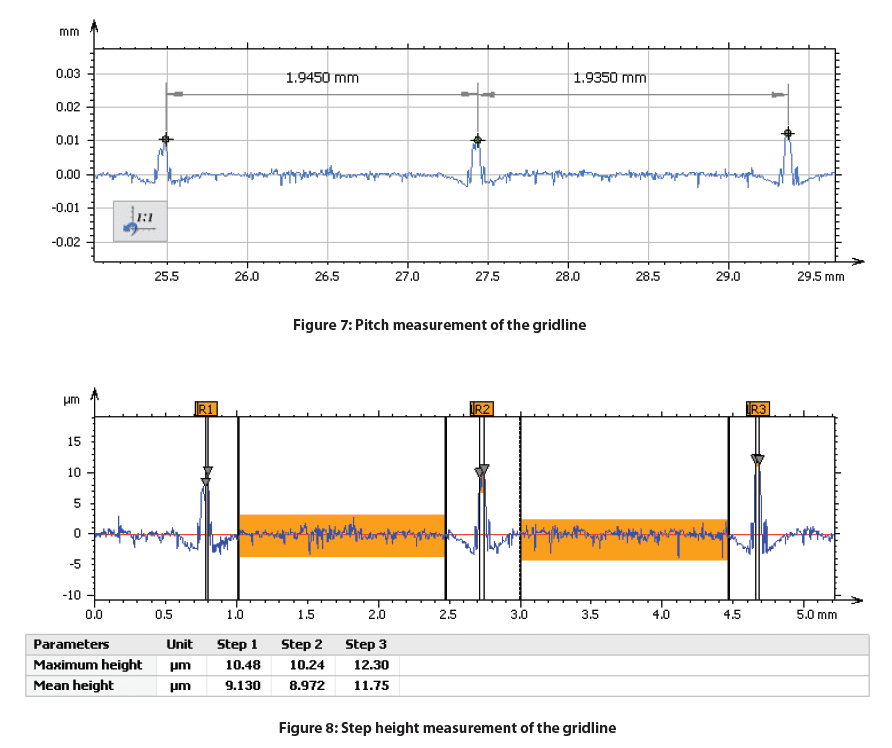

Rugosidad superficial y características de una célula solar

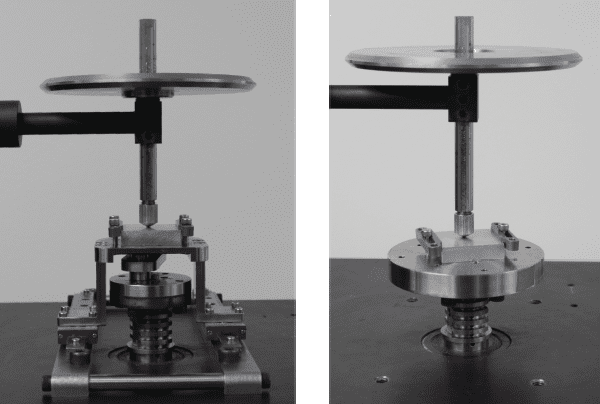

¿Desgaste Rotativo o Lineal y COF? (Un estudio exhaustivo con el tribómetro Nanovea)

El desgaste es el proceso de eliminación y deformación de material en una superficie como resultado de la acción mecánica de la superficie opuesta. En él influyen diversos factores, como el deslizamiento unidireccional, la rodadura, la velocidad, la temperatura y muchos otros. El estudio del desgaste, la tribología, abarca muchas disciplinas, desde la física y la química hasta la ingeniería mecánica y la ciencia de los materiales. La compleja naturaleza del desgaste requiere estudios aislados sobre mecanismos o procesos de desgaste específicos, como el desgaste adhesivo, el desgaste abrasivo, la fatiga superficial, el desgaste por rozamiento y el desgaste erosivo. Sin embargo, el "desgaste industrial" suele implicar múltiples mecanismos de desgaste que se producen en sinergia.

Los ensayos de desgaste lineal alternativo y rotativo (clavija sobre disco) son dos configuraciones ampliamente utilizadas de conformidad con ASTM para medir los comportamientos de desgaste por deslizamiento de los materiales. Dado que el valor de la tasa de desgaste de cualquier método de ensayo de desgaste se utiliza a menudo para predecir la clasificación relativa de las combinaciones de materiales, es extremadamente importante confirmar la repetibilidad de la tasa de desgaste medida utilizando diferentes configuraciones de ensayo. Esto permite a los usuarios considerar cuidadosamente el valor de la tasa de desgaste reportado en la literatura, lo cual es crítico para entender las características tribológicas de los materiales.

Más información

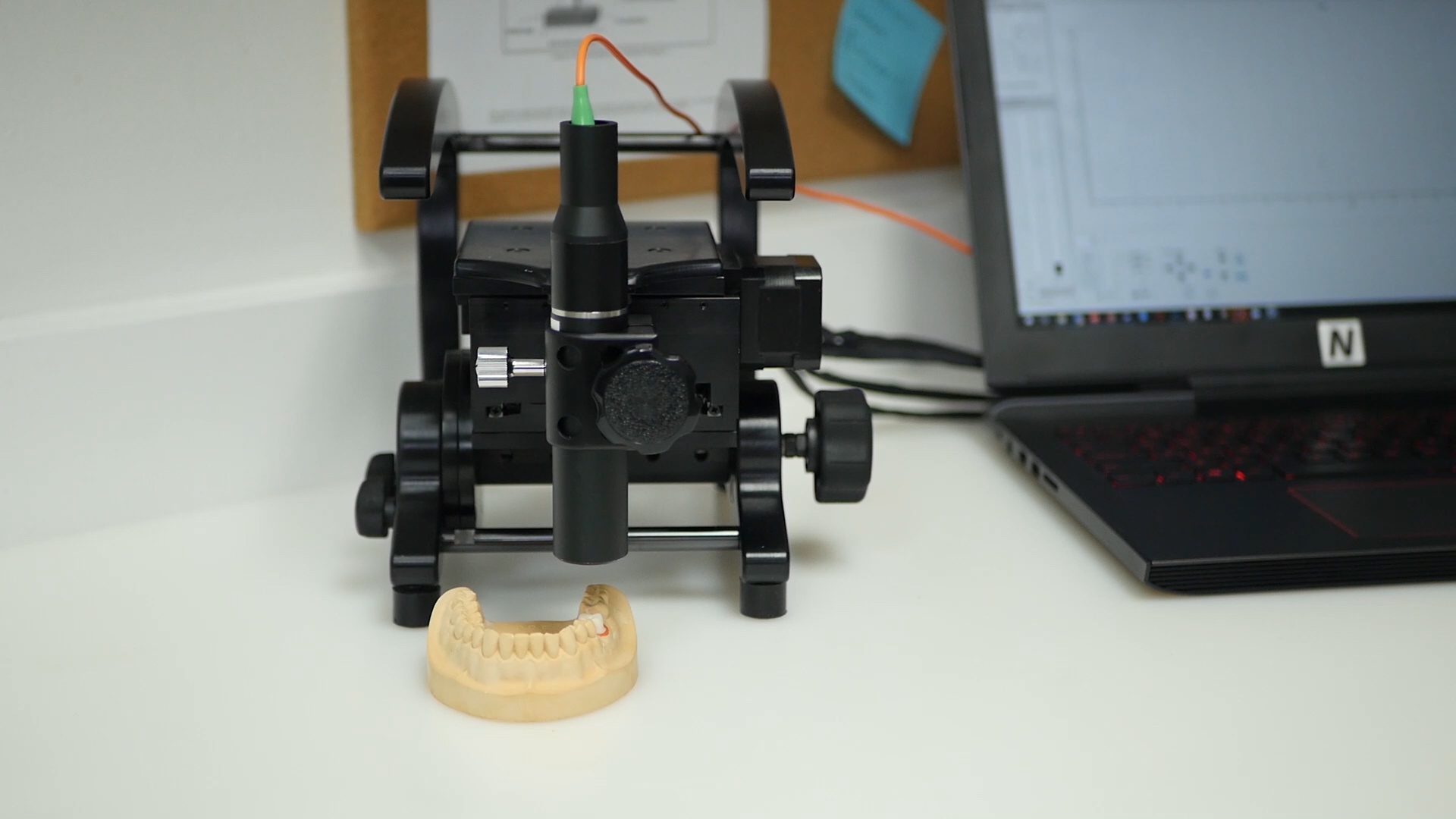

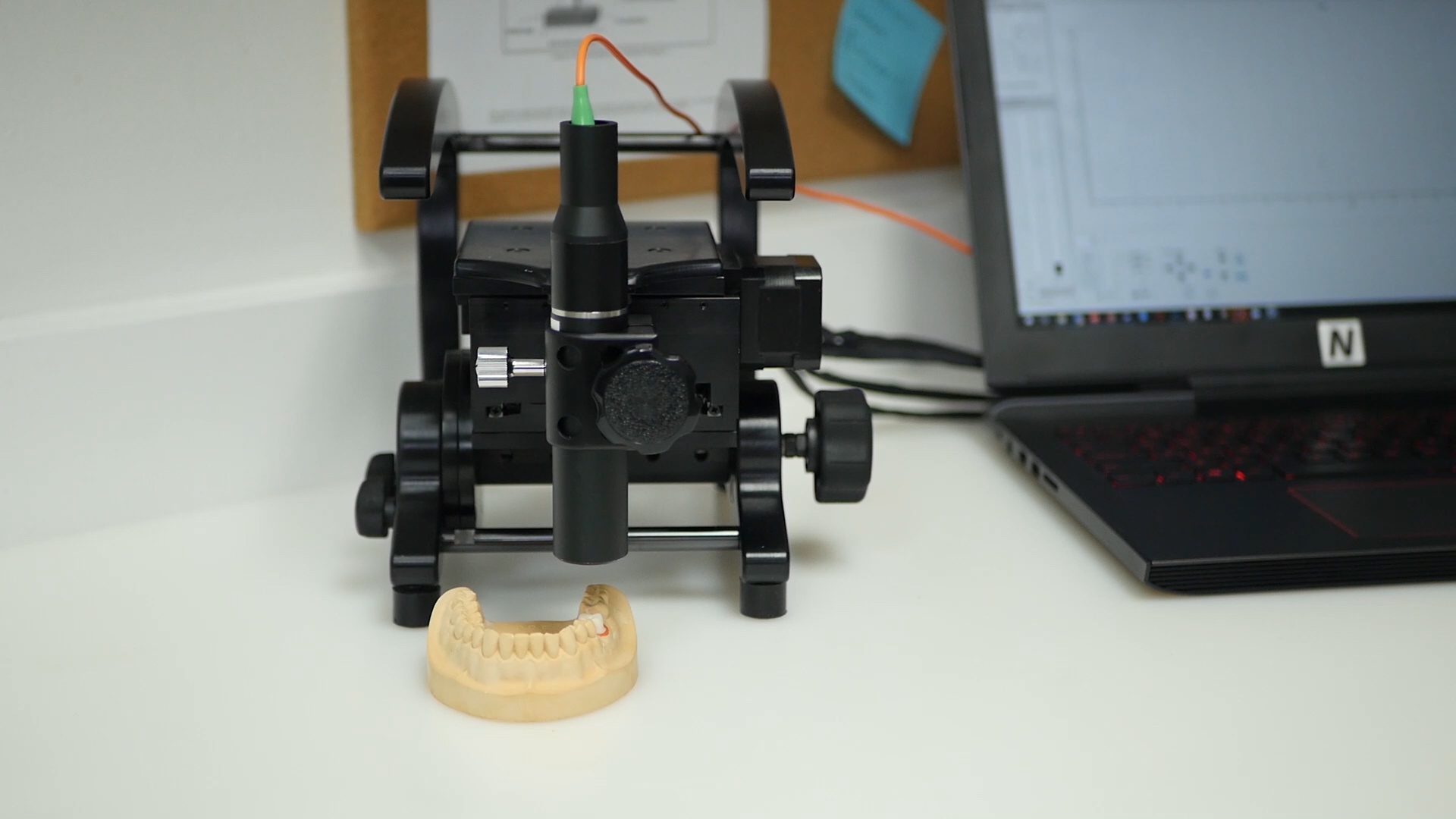

Portabilidad y flexibilidad del perfilómetro 3D sin contacto Jr25

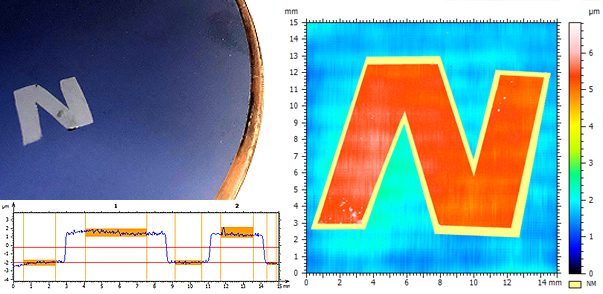

Altura del escalón de vidrio de 500 nm: precisión extrema con perfilometría sin contacto

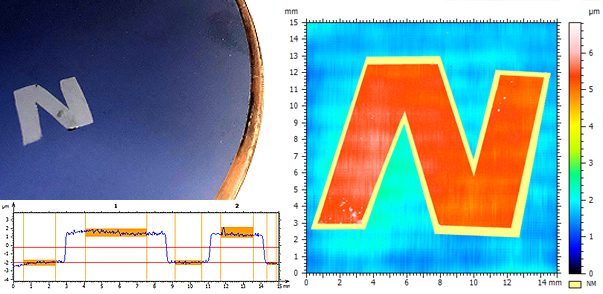

La caracterización de superficies es un tema de actualidad que está siendo objeto de intensos estudios. Las superficies de los materiales son importantes, ya que son las regiones donde se producen las interacciones físicas y químicas entre el material y el entorno. Por lo tanto, es deseable poder obtener imágenes de la superficie con alta resolución, ya que esto permite a los científicos observar visualmente los detalles más pequeños de la superficie. Los datos comunes de las imágenes de superficie incluyen la topografía, la rugosidad, las dimensiones laterales y las dimensiones verticales. La identificación de la superficie de carga, el espaciado y la altura de los escalones de las microestructuras fabricadas, y los defectos de la superficie son algunas de las aplicaciones que se pueden obtener a partir de las imágenes de superficie. Sin embargo, no todas las técnicas de obtención de imágenes de superficie son iguales.

Altura del escalón de vidrio de 500 nm: precisión extrema con perfilometría sin contacto

Medición del espesor del recubrimiento de obleas mediante perfilometría 3D

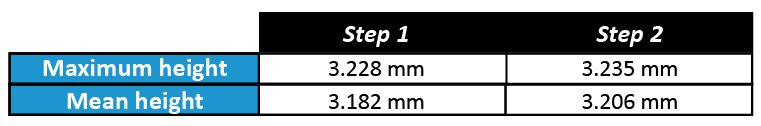

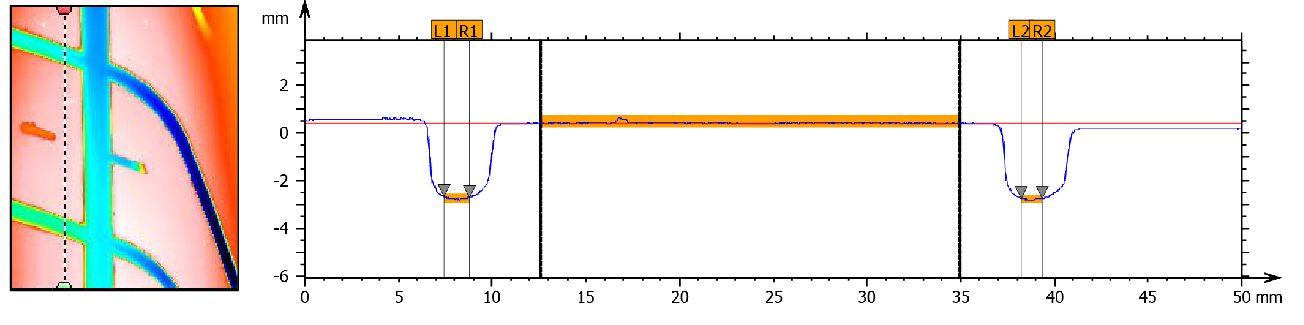

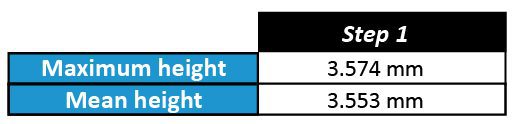

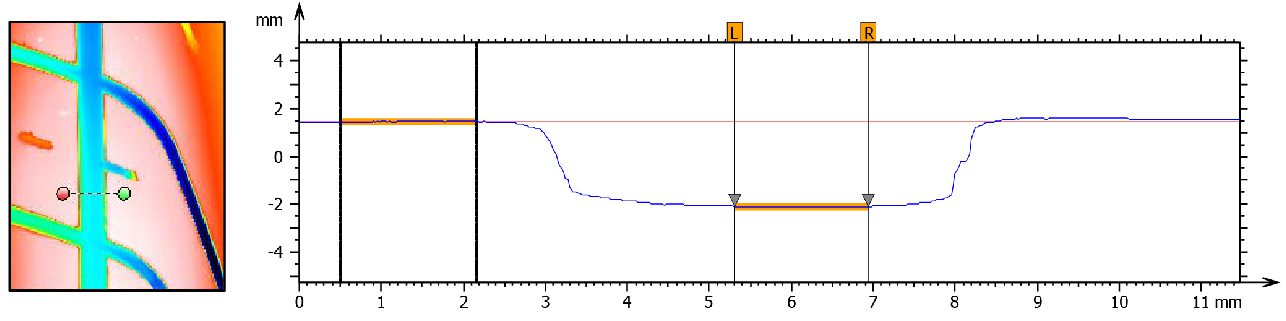

La medición del espesor del recubrimiento de las obleas es fundamental. Las obleas de silicio se utilizan ampliamente en la fabricación de circuitos integrados y otros microdispositivos utilizados en un gran número de industrias. La demanda constante de obleas y recubrimientos más finos y lisos hace que el Nanovea 3D sin contacto Perfilómetro Una excelente herramienta para cuantificar el espesor y la rugosidad del recubrimiento de prácticamente cualquier superficie. Las mediciones de este artículo se tomaron de una muestra de oblea recubierta con el fin de demostrar las capacidades de nuestro perfilómetro 3D sin contacto.

Medición del espesor del recubrimiento de obleas mediante perfilometría 3D