INTRODUCCIÓN

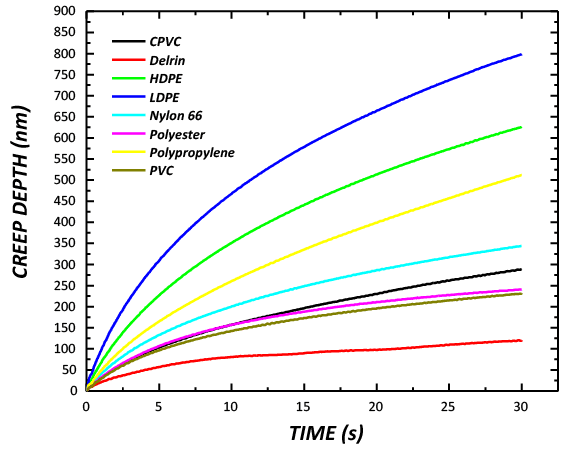

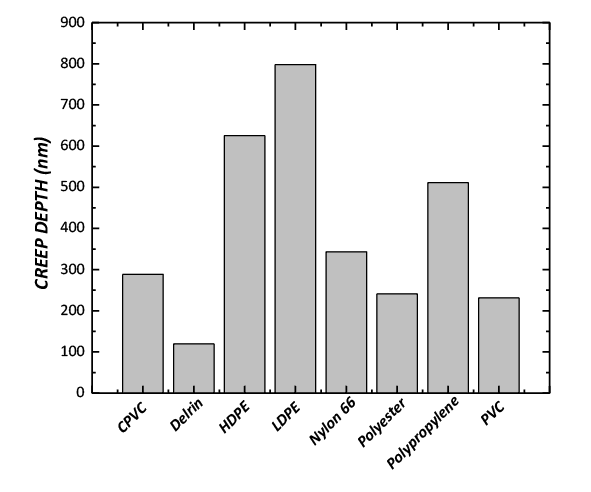

Como materiales viscoelásticos, los polímeros suelen sufrir una deformación dependiente del tiempo bajo una determinada carga aplicada, también conocida como fluencia. La fluencia se convierte en un factor crítico cuando las piezas poliméricas están diseñadas para estar expuestas a una tensión continua, como los componentes estructurales, las uniones y los accesorios, y los recipientes de presión hidrostática.

IMPORTANCIA DE LA MEDICIÓN DE LA FLUENCIA EN LOS POLÍMEROS

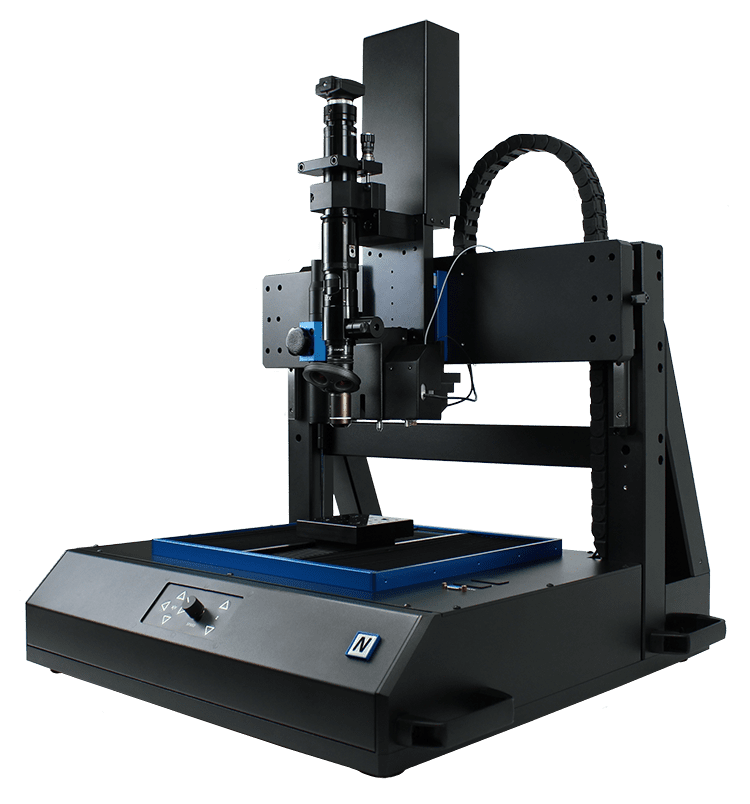

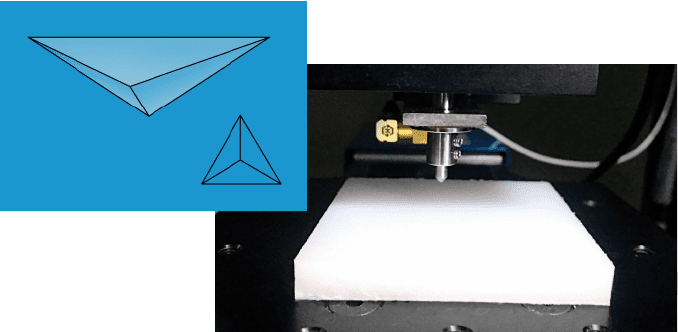

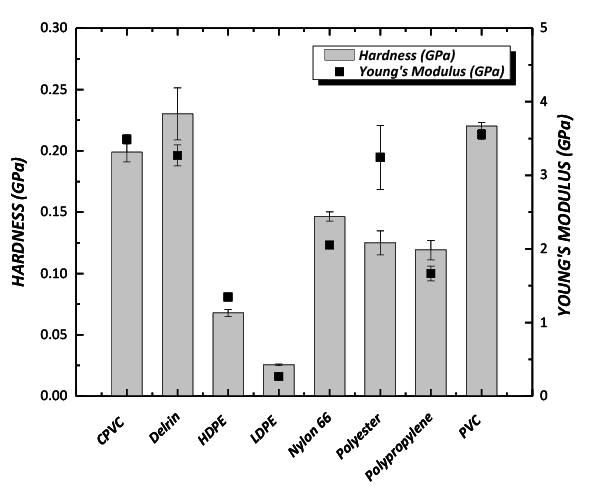

La naturaleza inherente de la viscoelasticidad desempeña un papel fundamental en el rendimiento de los polímeros e influye directamente en su fiabilidad de servicio. Las condiciones ambientales, como la carga y la temperatura, afectan al comportamiento de fluencia de los polímeros. Los fallos por fluencia suelen producirse debido a la falta de atención al comportamiento de fluencia dependiente del tiempo de los materiales poliméricos utilizados en condiciones de servicio específicas. Por ello, es importante desarrollar una prueba fiable y cuantitativa del comportamiento mecánico viscoelástico de los polímeros. El módulo Nano de NANOVEA Comprobadores mecánicos aplica la carga con un piezoeléctrico de alta precisión y mide directamente la evolución de la fuerza y el desplazamiento in situ. La combinación de precisión y repetibilidad lo convierte en una herramienta ideal para la medición de la fluencia.