¿Qué es la prueba de desgaste de pistones?

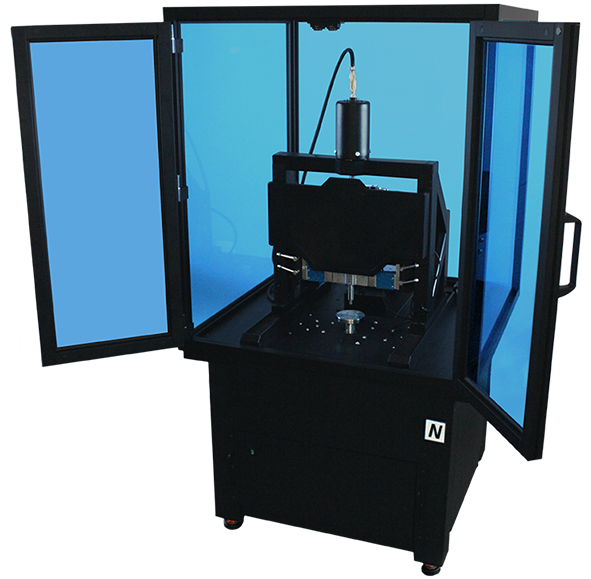

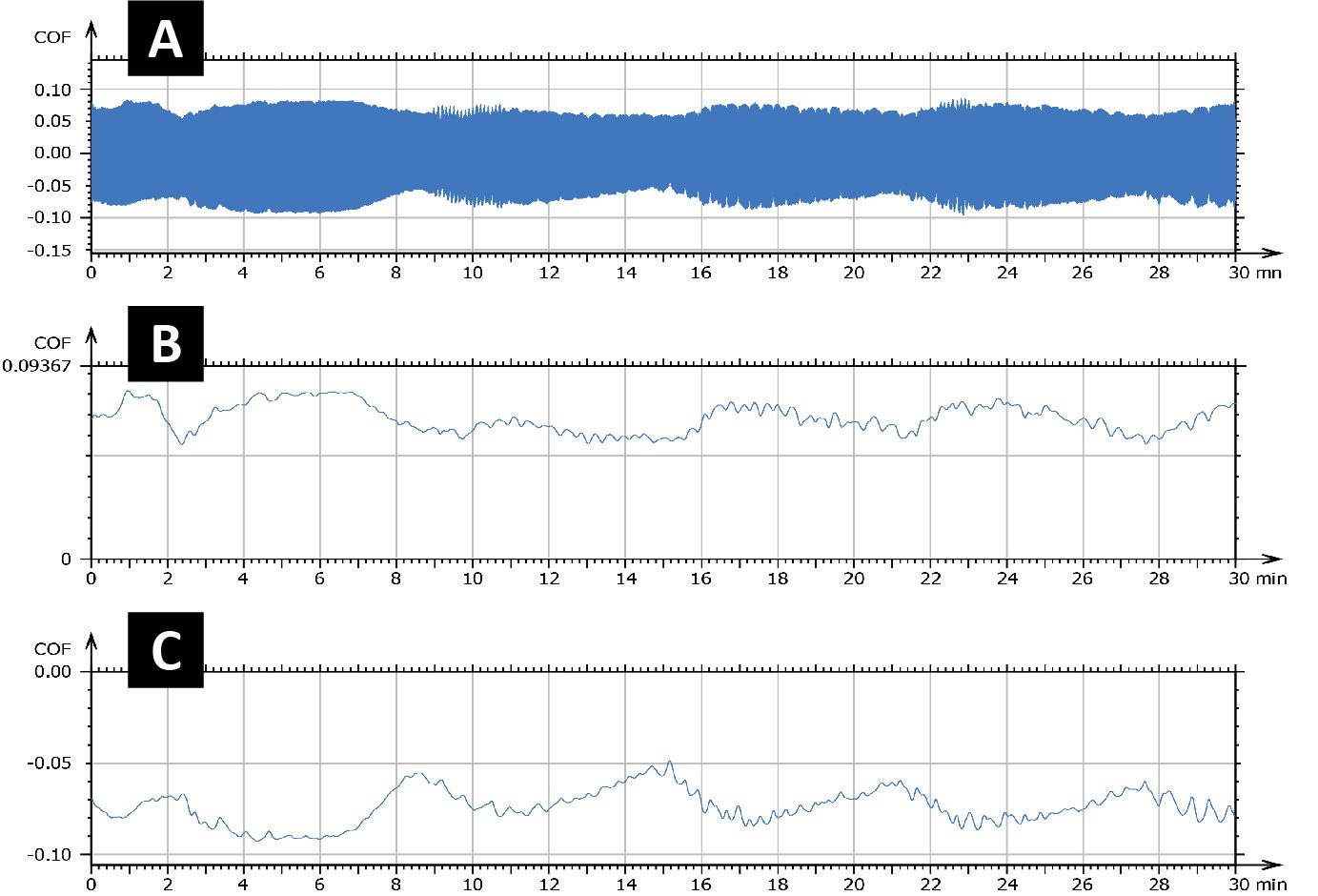

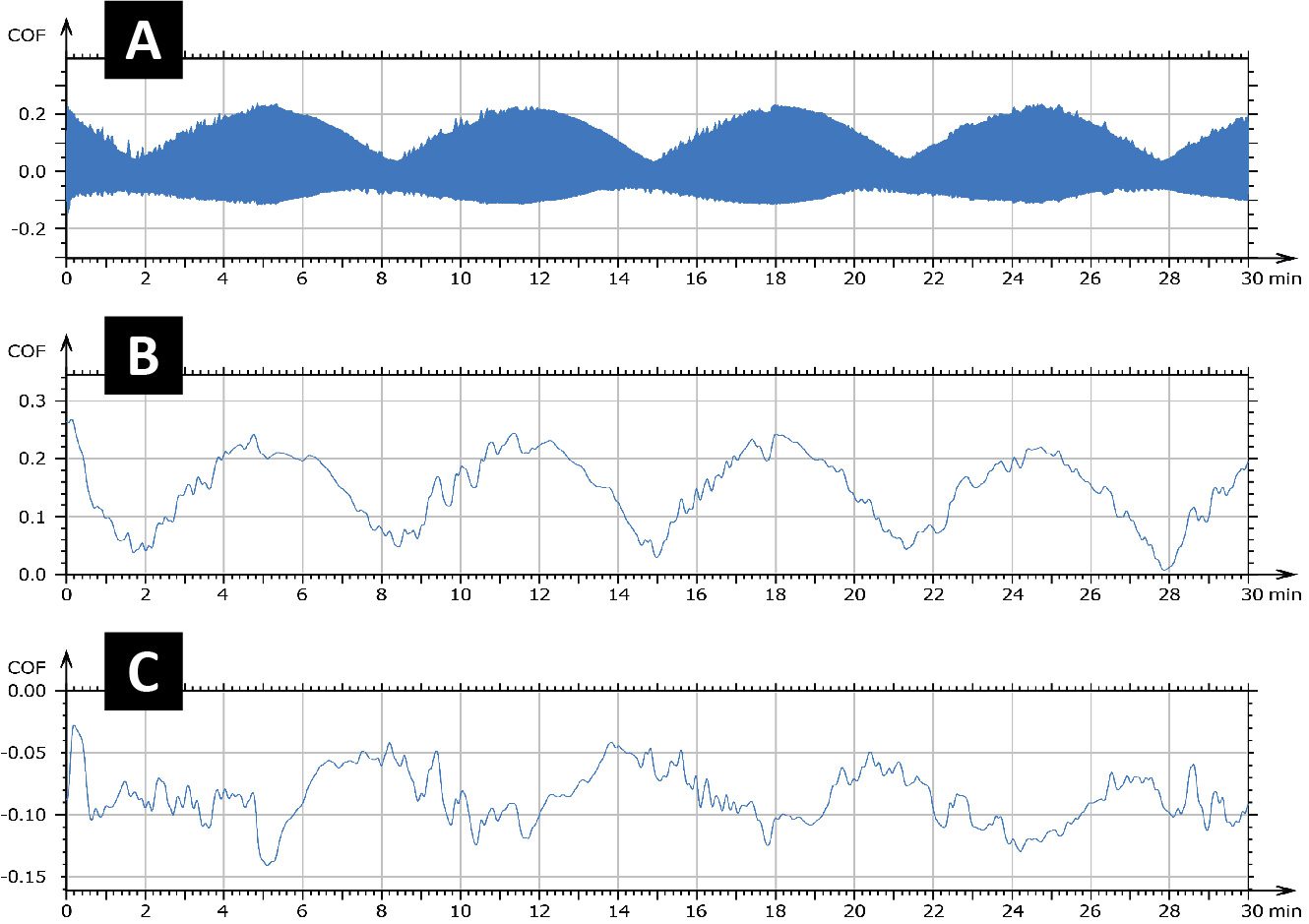

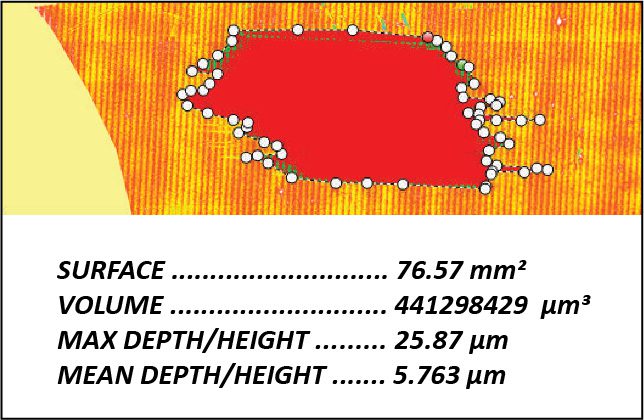

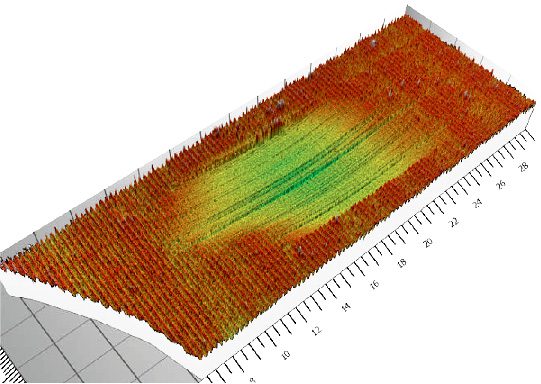

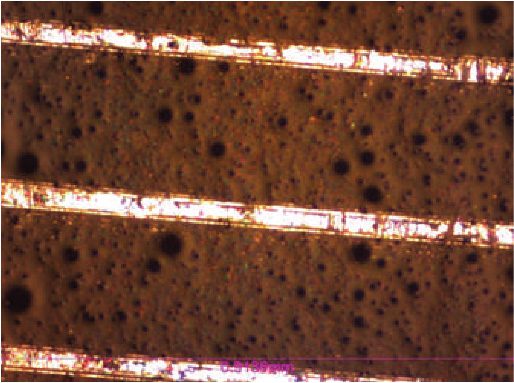

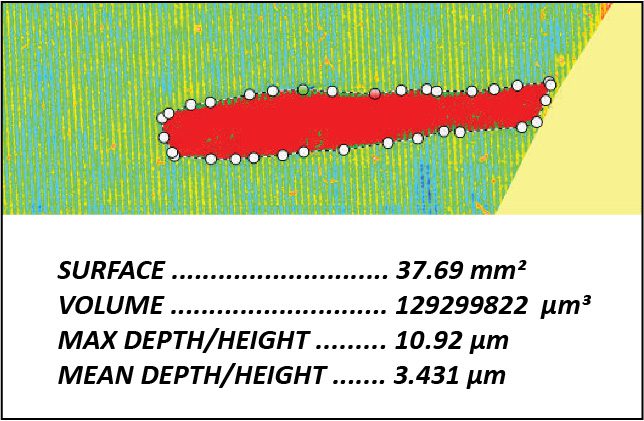

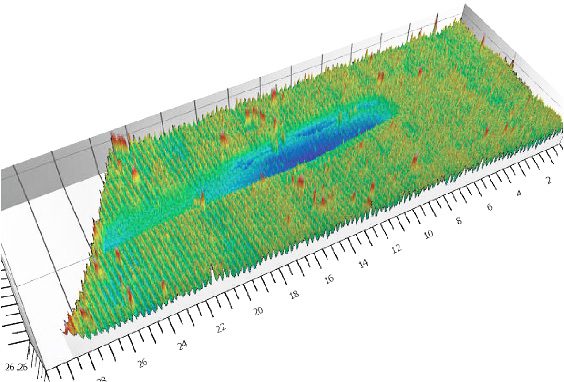

Las pruebas de desgaste de pistones evalúan la fricción, la lubricación y la durabilidad de los materiales entre las faldas de pistón y las camisas de cilindro en condiciones controladas de laboratorio. Utilizando un tribómetroLos ingenieros pueden reproducir el movimiento alternativo real y medir con precisión el coeficiente de fricción, la tasa de desgaste y la topografía de la superficie en 3D. Estos resultados proporcionan información clave sobre el comportamiento tribológico de los revestimientos, lubricantes y aleaciones utilizados en los pistones de los motores, ayudando a optimizar el rendimiento, la eficiencia del combustible y la fiabilidad a largo plazo.

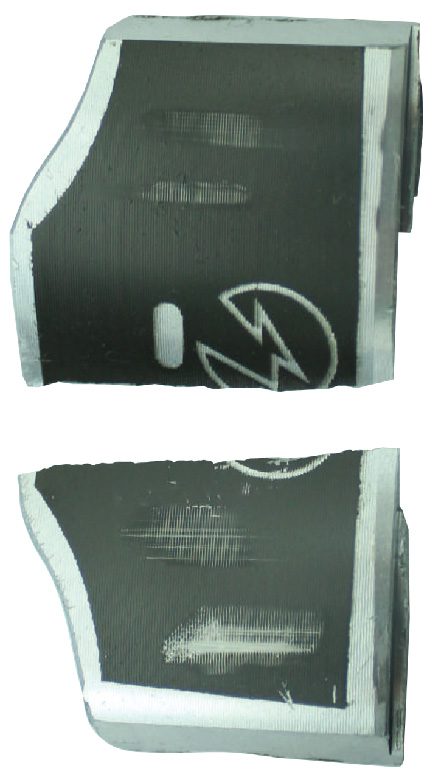

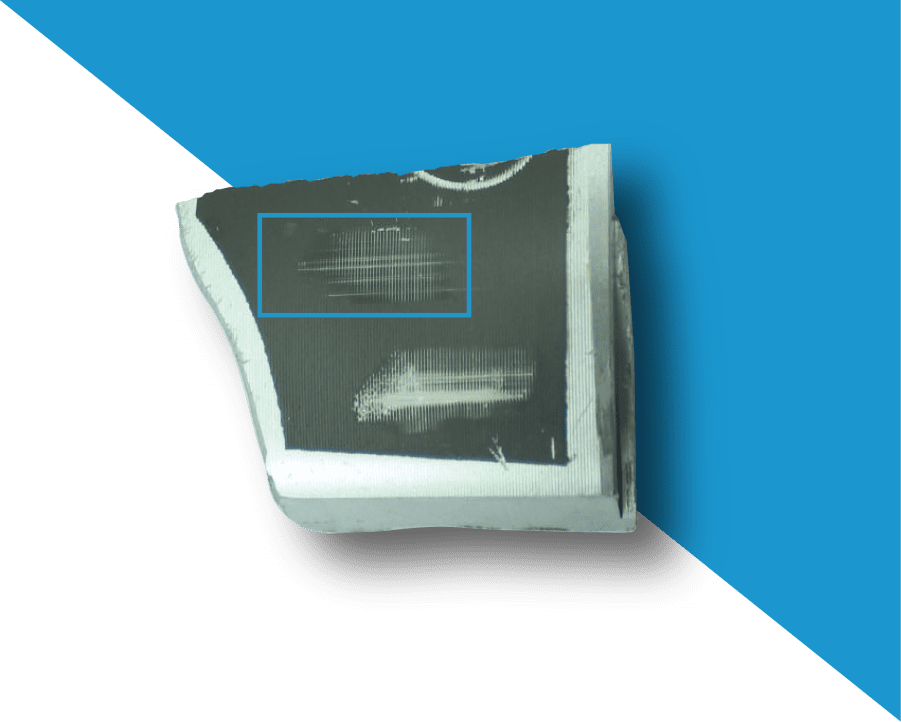

Esquema del sistema de cilindros de potencia e interfaces falda del pistón-lubricante-guarnición del cilindro.