Archivos mensuales: enero 2020

Acabado dimensional y superficial de los tubos poliméricos

Importancia del análisis dimensional y superficial de los tubos poliméricos

Los tubos fabricados con material polimérico se utilizan habitualmente en muchos sectores, como el automovilístico, el médico, el eléctrico y muchos otros. En este estudio, se analizaron catéteres médicos fabricados con diferentes materiales poliméricos utilizando Nanovea. Perfilómetro 3D sin contacto para medir la rugosidad, la morfología y las dimensiones de la superficie. La rugosidad de la superficie es crucial para los catéteres, ya que muchos de los problemas que estos presentan, como infecciones, traumatismos físicos e inflamaciones, pueden estar relacionados con la superficie del catéter. Las propiedades mecánicas, como el coeficiente de fricción, también pueden estudiarse observando las propiedades de la superficie. Estos datos cuantificables pueden obtenerse para garantizar que el catéter pueda utilizarse en aplicaciones médicas.

En comparación con la microscopía óptica y la microscopía electrónica, la perfilometría 3D sin contacto que utiliza cromatismo axial es muy recomendable para caracterizar las superficies de los catéteres debido a su capacidad para medir ángulos/curvaturas, medir superficies de materiales a pesar de su transparencia o reflectividad, la mínima preparación de muestras y su naturaleza no invasiva. A diferencia de la microscopía óptica convencional, se puede obtener la altura de la superficie y utilizarla para el análisis computacional; por ejemplo, para encontrar dimensiones y eliminar formas para determinar la rugosidad de la superficie. Al requerir poca preparación de la muestra, en contraste con la microscopía electrónica, y al ser de naturaleza no invasiva, también permite una rápida recopilación de datos sin temor a la contaminación y los errores derivados de la preparación de la muestra.

Objetivo de medición

En esta aplicación, se utiliza el perfilómetro sin contacto Nanovea 3D para escanear la superficie de dos catéteres: uno fabricado en TPE (elastómero termoplástico) y otro en PVC (cloruro de polivinilo). Se obtendrán y compararán los parámetros de morfología, dimensión radial y altura de los dos catéteres.

Resultados y debate

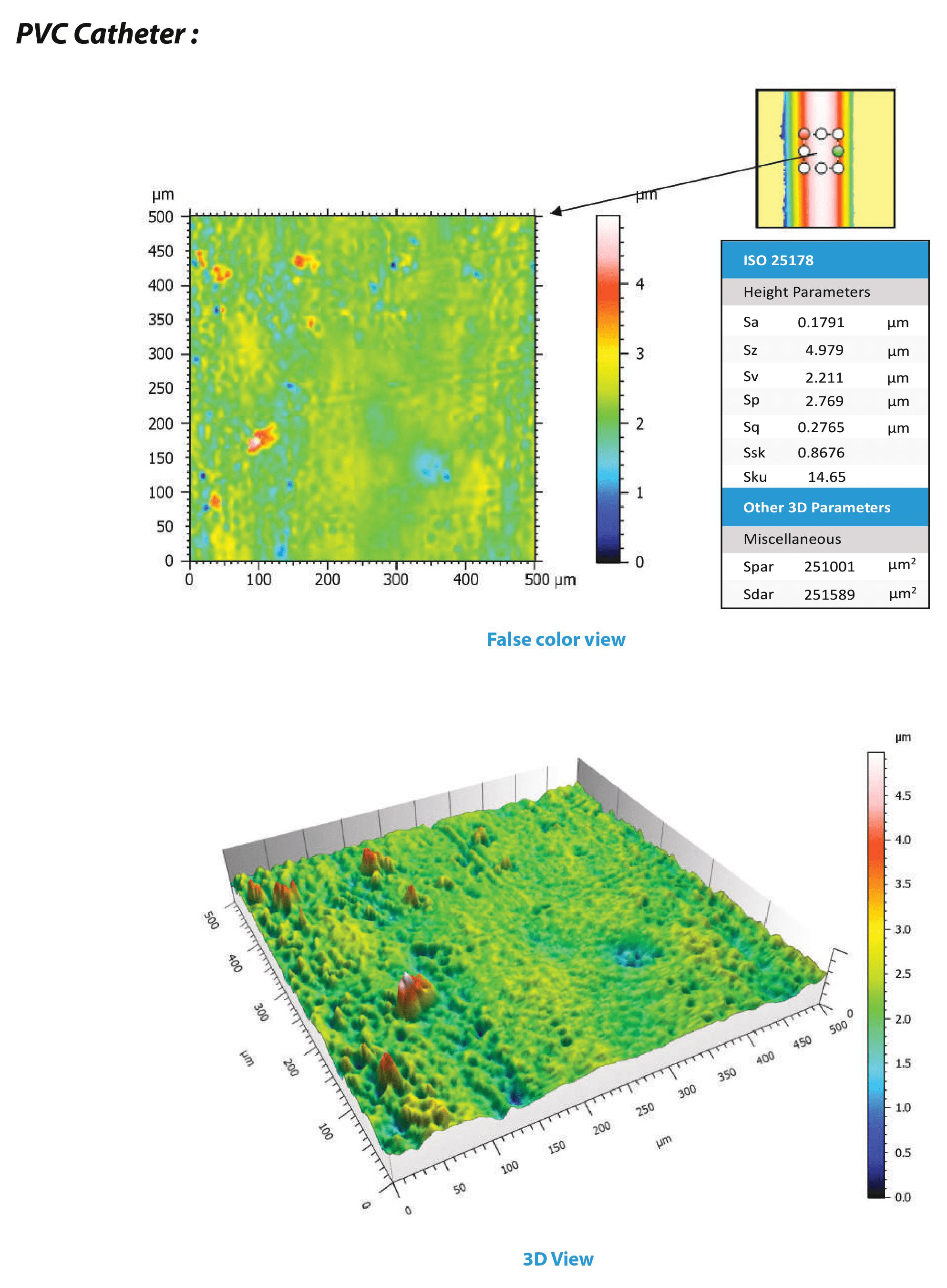

Superficie 3D

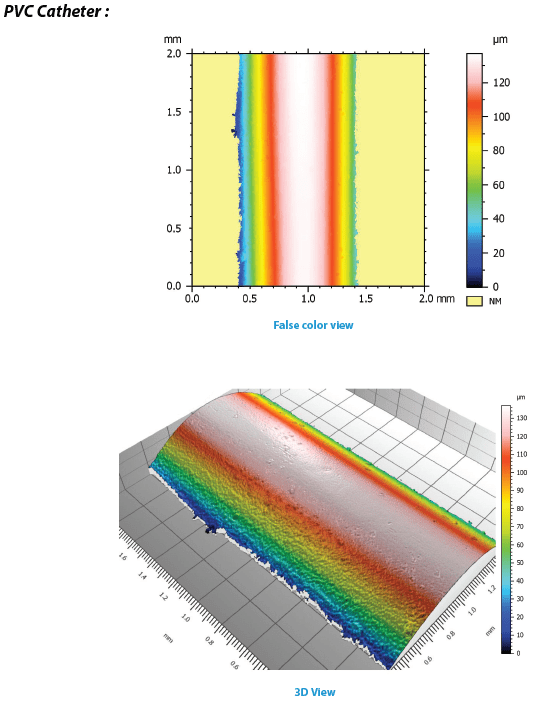

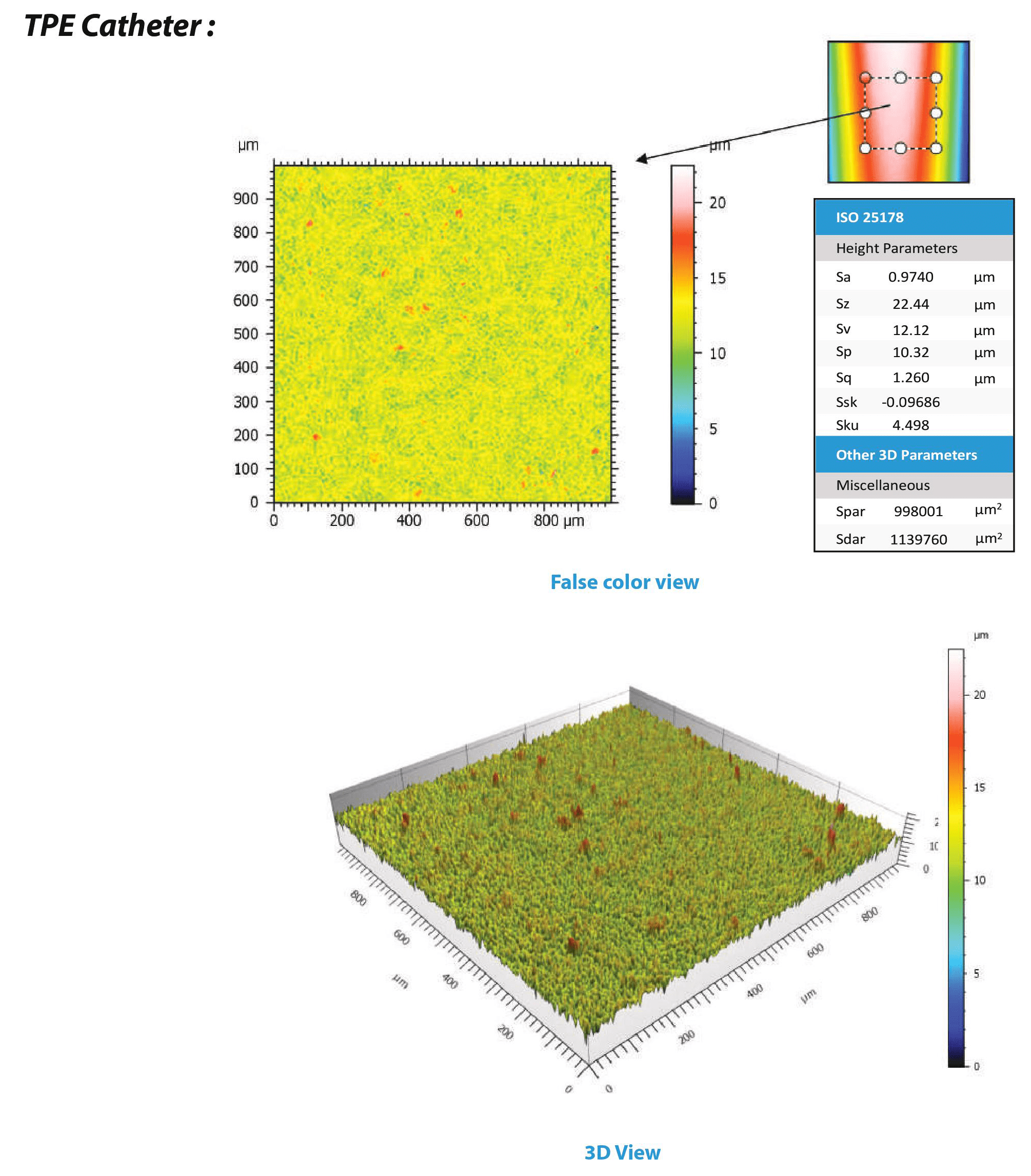

A pesar de la curvatura de los tubos poliméricos, el perfilómetro sin contacto Nanovea 3D puede escanear la superficie de los catéteres. A partir del escaneo realizado, se puede obtener una imagen 3D para una inspección visual rápida y directa de la superficie.

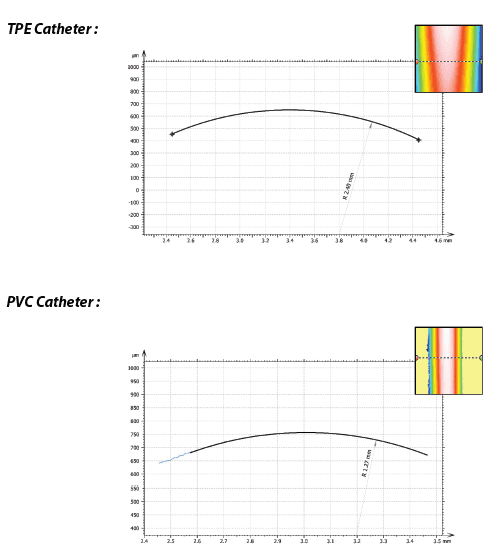

La dimensión radial exterior se obtuvo extrayendo un perfil del escaneo original y ajustando un arco al perfil. Esto demuestra la capacidad del perfilómetro 3D sin contacto para realizar análisis dimensionales rápidos para aplicaciones de control de calidad. También se pueden obtener fácilmente múltiples perfiles a lo largo de la longitud del catéter.

La dimensión radial exterior se obtuvo extrayendo un perfil del escaneo original y ajustando un arco al perfil. Esto demuestra la capacidad del perfilómetro 3D sin contacto para realizar análisis dimensionales rápidos para aplicaciones de control de calidad. También se pueden obtener fácilmente múltiples perfiles a lo largo de la longitud del catéter.

Conclusión

En esta aplicación, hemos mostrado cómo se puede utilizar el perfilómetro sin contacto Nanovea 3D para caracterizar tubos poliméricos. En concreto, se obtuvieron datos de metrología superficial, dimensiones radiales y rugosidad superficial de catéteres médicos. Se determinó que el radio exterior del catéter de TPE era de 2,40 mm, mientras que el del catéter de PVC era de 1,27 mm. Se observó que la superficie del catéter de TPE era más rugosa que la del catéter de PVC. El Sa del TPE era de 0,9740 µm, en comparación con los 0,1791 µm del PVC. Aunque para esta aplicación se utilizaron catéteres médicos, la perfilometría 3D sin contacto también se puede aplicar a una gran variedad de superficies. Los datos y cálculos que se pueden obtener no se limitan a los que se muestran.

AHORA, HABLEMOS DE SU SOLICITUD

Evaluación de la dureza dental mediante nanoindentación

Importancia de la nanoindentación para los biomateriales

Con muchas pruebas mecánicas tradicionales (dureza, adhesión, compresión, perforación, límite elástico, etc.), los entornos actuales de control de calidad con materiales sensibles avanzados, desde geles hasta materiales frágiles, requieren ahora un mayor control de la precisión y la fiabilidad. Los instrumentos mecánicos tradicionales no proporcionan el control de carga sensible y la resolución necesarios, ya que están diseñados para utilizarse con materiales a granel. A medida que el tamaño de los materiales sometidos a prueba cobró mayor interés, se desarrolló Nanoindentación proporcionó un método confiable para obtener información mecánica esencial en superficies más pequeñas, como la investigación que se realiza con biomateriales. Los retos específicos asociados a los biomateriales han requerido el desarrollo de ensayos mecánicos capaces de controlar con precisión la carga en materiales extremadamente blandos o frágiles. Además, se necesitan múltiples instrumentos para realizar diversos ensayos mecánicos que ahora pueden llevarse a cabo en un solo sistema. La nanoindentación proporciona una amplia gama de mediciones con una resolución precisa a cargas controladas a nanoescala para aplicaciones sensibles.

Objetivo de medición

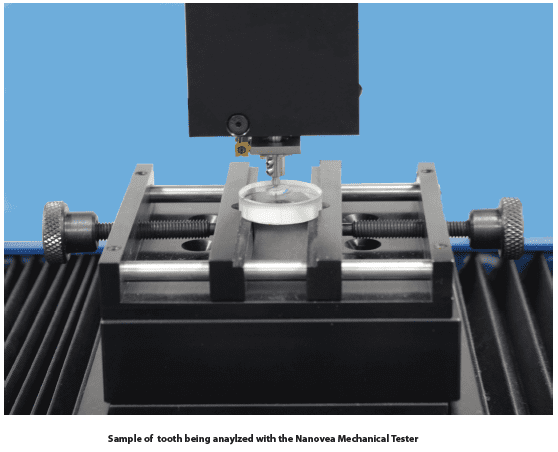

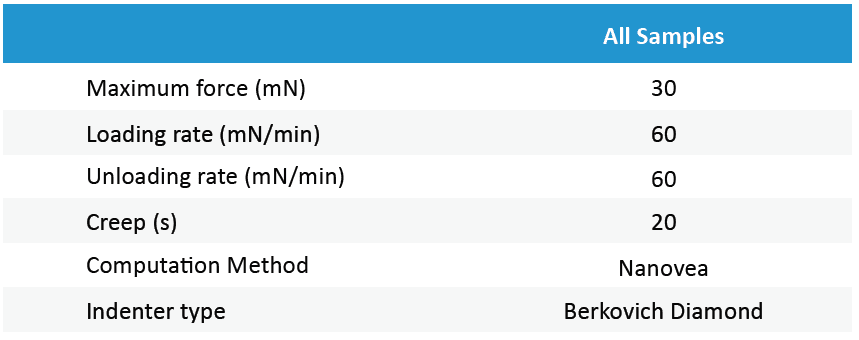

En esta aplicación, Nanovea Comprobador mecánico, en modo nanoindentación, se utiliza para estudiar la dureza y el módulo elástico de la dentina, la caries y la pulpa de un diente. El aspecto más crítico de las pruebas de nanoindentación es asegurar la muestra. En este caso, tomamos un diente cortado y lo montamos con epoxi, dejando expuestas las tres áreas de interés para la prueba.

Resultados y debate

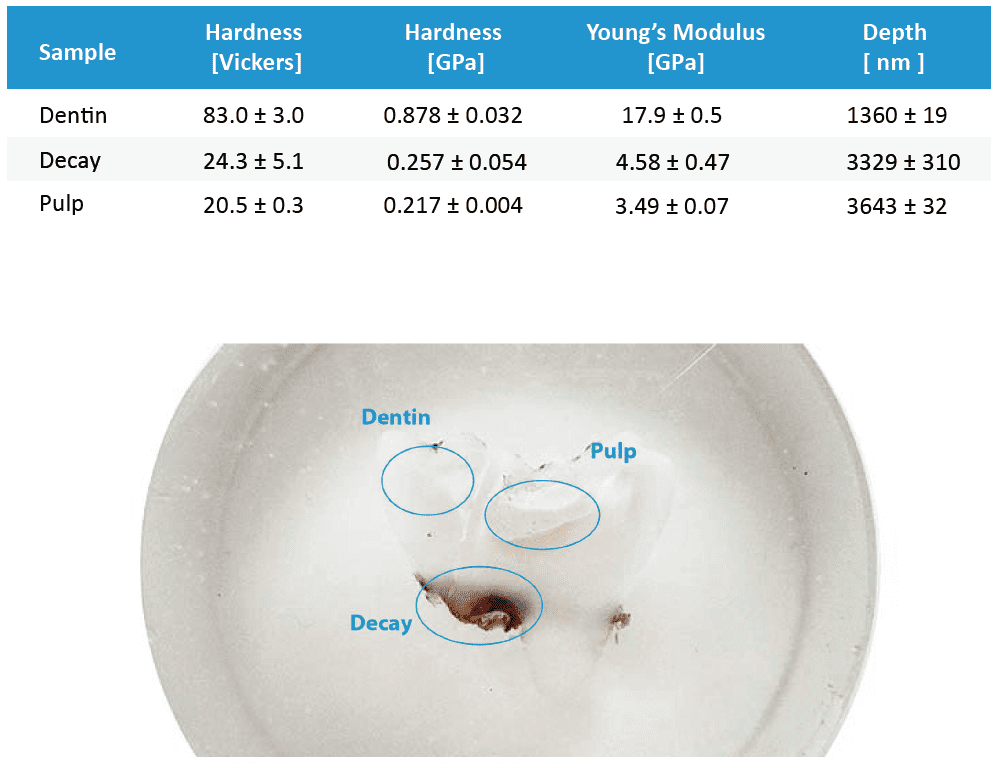

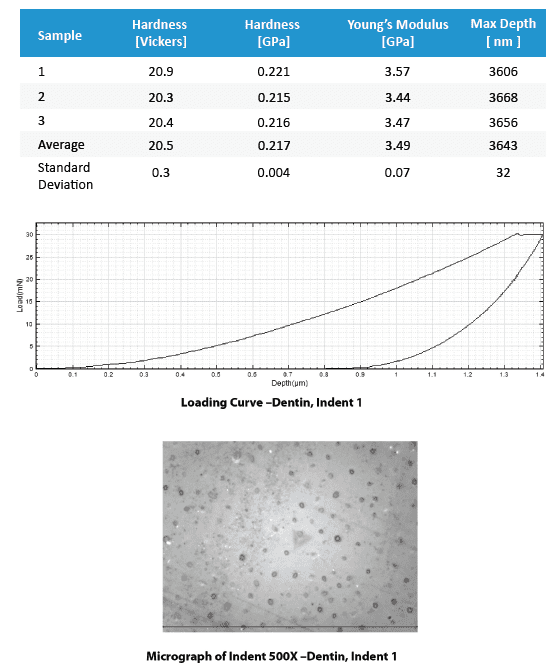

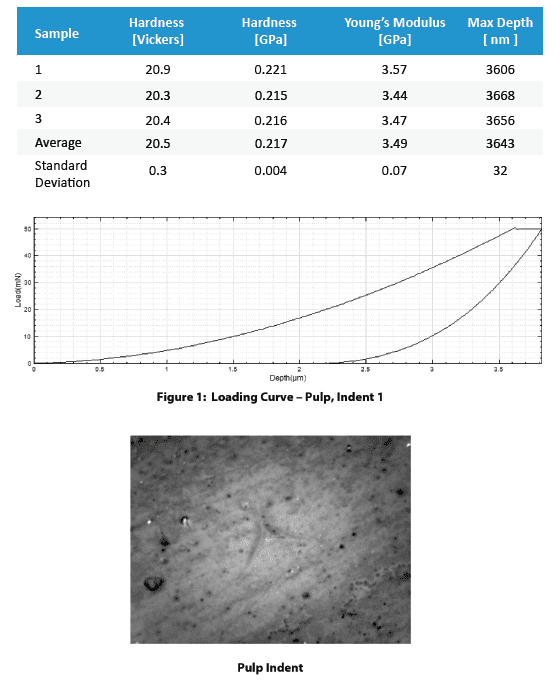

Esta sección incluye una tabla resumen que compara los principales resultados numéricos de las diferentes muestras, seguida de la lista completa de resultados, incluyendo cada indentación realizada, acompañada de micrografías de la indentación, cuando están disponibles. Estos resultados completos presentan los valores medidos de dureza y módulo de Young como la profundidad de penetración con sus promedios y desviaciones estándar. Debe tenerse en cuenta que pueden producirse grandes variaciones en los resultados en caso de que la rugosidad de la superficie se encuentre en el mismo rango de tamaño que la indentación.

Cuadro resumen de los principales resultados numéricos:

Conclusión

En conclusión, hemos demostrado cómo el Nanovea Mechanical Tester, en modo nanoindentación, proporciona una medición precisa de las propiedades mecánicas de un diente. Los datos pueden utilizarse en el desarrollo de empastes que se adapten mejor a las características mecánicas de un diente real. La capacidad de posicionamiento del Nanovea Mechanical Tester permite realizar un mapeo completo de la dureza de los dientes en las distintas zonas.

Utilizando el mismo sistema, es posible probar la resistencia a la fractura del material dental con cargas más elevadas, de hasta 200 N. Se puede realizar una prueba de carga multiciclo en materiales más porosos para evaluar el nivel de elasticidad restante. El uso de una punta de diamante cilíndrica plana puede proporcionar información sobre el límite elástico en cada zona. Además, con el “análisis mecánico dinámico” (DMA), se pueden evaluar las propiedades viscoelásticas, incluidos los módulos de pérdida y almacenamiento.

El nanomódulo Nanovea es ideal para estas pruebas porque utiliza una respuesta de retroalimentación única para controlar con precisión la carga aplicada. Gracias a ello, el nanomódulo también se puede utilizar para realizar pruebas precisas de nanoarañazos. El estudio de la resistencia al rayado y al desgaste de los materiales dentales y de obturación aumenta la utilidad general del probador mecánico. El uso de una punta afilada de 2 micras para comparar cuantitativamente el desgaste de los materiales de obturación permitirá predecir mejor el comportamiento en aplicaciones reales. Las pruebas de desgaste multipaso o de desgaste rotativo directo también son pruebas comunes que proporcionan información importante sobre la viabilidad a largo plazo.

AHORA, HABLEMOS DE SU SOLICITUD

Evaluación de la fricción a velocidades extremadamente bajas

Importancia de la evaluación de la fricción a bajas velocidades

La fricción es la fuerza que se opone al movimiento relativo de superficies sólidas que se deslizan unas contra otras. Cuando se produce el movimiento relativo de estas dos superficies en contacto, la fricción en la interfaz convierte la energía cinética en calor. Este proceso también puede provocar el desgaste del material y, por lo tanto, la degradación del rendimiento de las piezas en uso.

Con un gran índice de elasticidad, alta resistencia, así como excelentes propiedades impermeables y resistencia al desgaste, el caucho se utiliza ampliamente en una gran variedad de aplicaciones y productos en los que la fricción juega un papel importante, como los neumáticos de automóvil, las escobillas limpiaparabrisas, las suelas de zapatos y muchos otros. Dependiendo de la naturaleza y los requisitos de estas aplicaciones, se requiere una fricción alta o baja con respecto a diferentes materiales. Por consiguiente, resulta fundamental realizar una medición controlada y fiable de la fricción del caucho con respecto a diversas superficies.

Objetivo de medición

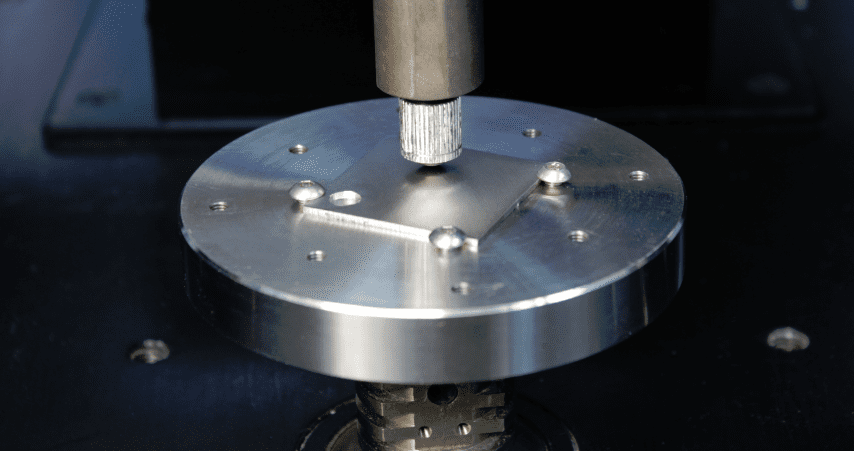

El coeficiente de fricción (COF) del caucho con respecto a diferentes materiales se mide de forma controlada y supervisada utilizando el Nanovea. Tribómetro. En este estudio, nos gustaría mostrar la capacidad del tribómetro Nanovea para medir el coeficiente de fricción (COF) de diferentes materiales a velocidades extremadamente bajas.

Resultados y debate

El coeficiente de fricción (COF) de bolas de caucho (6 mm de diámetro, RubberMill) sobre tres materiales (acero inoxidable SS 316, Cu 110 y acrílico opcional) se evaluó mediante el tribómetro Nanovea. Las muestras metálicas sometidas a prueba se pulieron mecánicamente hasta obtener un acabado superficial similar al de un espejo antes de la medición. La ligera deformación de la bola de caucho bajo la carga normal aplicada creó un área de contacto, lo que también ayuda a reducir el impacto de las asperezas o la falta de homogeneidad del acabado de la superficie de la muestra en las mediciones del COF. Los parámetros de la prueba se resumen en la tabla 1.

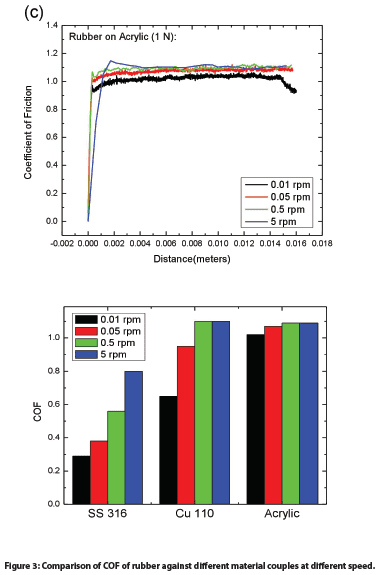

El COF de una pelota de goma contra diferentes materiales a cuatro velocidades diferentes se muestra en la figura 2, y los COF medios calculados automáticamente por el software se resumen y comparan en la figura 3. Es interesante observar que las muestras metálicas (SS 316 y Cu 110) muestran un aumento significativo de los COF a medida que la velocidad de rotación aumenta desde un valor muy bajo de 0,01 rpm hasta 5 rpm: el valor del COF del par caucho/SS 316 aumenta de 0,29 a 0,8, y de 0,65 a 1,1 para el par caucho/Cu 110. Este hallazgo concuerda con los resultados comunicados por varios laboratorios. Tal y como propone Grosch4 La fricción del caucho viene determinada principalmente por dos mecanismos: (1) la adhesión entre el caucho y el otro material, y (2) las pérdidas de energía debidas a la deformación del caucho causada por las asperezas de la superficie. Schallamach5 Se observaron ondas de desprendimiento del caucho del material de contraposición a lo largo de la interfaz entre las esferas de caucho blando y una superficie dura. La fuerza necesaria para que el caucho se desprenda de la superficie del sustrato y la velocidad de las ondas de desprendimiento pueden explicar las diferentes fricciones observadas a distintas velocidades durante la prueba.

En comparación, la combinación de caucho y acrílico presenta un alto COF a diferentes velocidades de rotación. El valor del COF aumenta ligeramente de ~ 1,02 a ~ 1,09 a medida que la velocidad de rotación aumenta de 0,01 rpm a 5 rpm. Es posible que este alto COF se deba a una unión química local más fuerte en la superficie de contacto formada durante las pruebas.

Conclusión

En este estudio, demostramos que, a velocidades extremadamente bajas, el caucho presenta un comportamiento de fricción peculiar: su fricción contra una superficie dura aumenta con el incremento de la velocidad del movimiento relativo. El caucho muestra una fricción diferente cuando se desliza sobre distintos materiales. El tribómetro Nanovea puede evaluar las propiedades de fricción de los materiales de forma controlada y supervisada a diferentes velocidades, lo que permite a los usuarios mejorar su comprensión fundamental del mecanismo de fricción de los materiales y seleccionar el mejor par de materiales para aplicaciones de ingeniería tribológica específicas.

El tribómetro Nanovea ofrece pruebas de desgaste y fricción precisas y repetibles utilizando modos rotativos y lineales que cumplen con las normas ISO y ASTM, con módulos opcionales de desgaste a alta temperatura, lubricación y tribocorrosión disponibles en un sistema preintegrado. Es capaz de controlar la etapa rotativa a velocidades extremadamente bajas, de hasta 0,01 rpm, y supervisar la evolución de la fricción in situ. La inigualable gama de Nanovea es una solución ideal para determinar todas las propiedades tribológicas de recubrimientos, películas y sustratos finos o gruesos, blandos o duros.

AHORA, HABLEMOS DE SU SOLICITUD

Categorías

- Notas de aplicación

- Bloque sobre tribología anular

- Tribología de la corrosión

- Pruebas de fricción | Coeficiente de fricción

- Pruebas mecánicas a alta temperatura

- Tribología de alta temperatura

- Humedad y gases Tribología

- Humedad Pruebas mecánicas

- Indentación | Fluencia y relajación

- Indentación | Resistencia a la fractura

- Indentación | Dureza y elasticidad

- Indentación | Pérdida y almacenamiento

- Indentación | Esfuerzo frente a deformación

- Indentación | Límite elástico y fatiga

- Pruebas de laboratorio

- Tribología lineal

- Pruebas mecánicas de líquidos

- Tribología de líquidos

- Tribología a baja temperatura

- Pruebas mecánicas

- Comunicado de prensa

- Perfilometría | Planitud y alabeo

- Perfilometría | Geometría y forma

- Perfilometría | Rugosidad y acabado

- Profilometría | Altura y grosor del escalón

- Profilometría | Textura y grano

- Perfilometría | Volumen y área

- Pruebas de perfilometría

- Tribología anillo sobre anillo

- Tribología rotacional

- Prueba de arañazos | Fallo adhesivo

- Prueba del rasguño | Fallo de cohesión

- Pruebas de arañazos | Desgaste en varias pasadas

- Pruebas de rayado | Dureza al rayado

- Pruebas de rayado Tribología

- Pruebas de tribología

- Sin categoría

Archivos

- noviembre 2025

- septiembre 2023

- agosto 2023

- junio 2023

- mayo 2023

- julio 2022

- mayo 2022

- abril 2022

- enero 2022

- diciembre 2021

- noviembre 2021

- octubre 2021

- septiembre 2021

- agosto 2021

- julio 2021

- junio 2021

- mayo 2021

- marzo 2021

- febrero 2021

- diciembre 2020

- noviembre 2020

- octubre 2020

- septiembre 2020

- julio 2020

- mayo 2020

- abril 2020

- marzo 2020

- febrero 2020

- enero 2020

- noviembre 2019

- octubre 2019

- septiembre 2019

- agosto 2019

- julio 2019

- junio 2019

- mayo 2019

- abril 2019

- marzo 2019

- enero 2019

- diciembre 2018

- noviembre 2018

- octubre 2018

- septiembre 2018

- julio 2018

- junio 2018

- abril 2018

- marzo 2018

- febrero 2018

- noviembre 2017

- octubre 2017

- septiembre 2017

- agosto 2017

- junio 2017

- mayo 2017

- marzo 2017

- febrero 2017

- enero 2017

- noviembre 2016

- octubre 2016

- agosto 2016

- julio 2016

- junio 2016

- mayo 2016

- abril 2016

- marzo 2016

- febrero 2016

- enero 2016

- diciembre 2015

- noviembre 2015

- octubre 2015

- septiembre 2015

- agosto 2015

- julio 2015

- junio 2015

- mayo 2015

- abril 2015

- marzo 2015

- febrero 2015

- enero 2015

- noviembre 2014

- octubre 2014

- septiembre 2014

- agosto 2014

- julio 2014

- junio 2014

- mayo 2014

- abril 2014

- marzo 2014

- febrero 2014

- enero 2014

- diciembre 2013

- noviembre 2013

- octubre 2013

- septiembre 2013

- agosto 2013

- julio 2013

- junio 2013

- mayo 2013

- abril 2013

- marzo 2013

- febrero 2013

- enero 2013

- diciembre 2012

- noviembre 2012

- octubre 2012

- septiembre 2012

- agosto 2012

- julio 2012

- junio 2012

- mayo 2012

- abril 2012

- marzo 2012

- febrero 2012

- enero 2012

- diciembre 2011

- noviembre 2011

- octubre 2011

- septiembre 2011

- agosto 2011

- julio 2011

- junio 2011

- mayo 2011

- noviembre 2010

- enero 2010

- abril 2009

- marzo 2009

- enero 2009

- diciembre 2008

- octubre 2008

- agosto 2007

- julio 2006

- marzo 2006

- enero 2005

- abril 2004