Categoría: Pruebas de laboratorio

Análisis de la textura de la piel de naranja de la pintura mediante perfilometría 3D

Análisis de la textura de la piel de naranja de la pintura mediante perfilometría 3D

Introducción

El tamaño y la frecuencia de las estructuras superficiales de los sustratos afectan a la calidad de los recubrimientos brillantes. La textura de piel de naranja de la pintura, llamada así por su aspecto, puede desarrollarse debido a la influencia del sustrato y a la técnica de aplicación de la pintura. Los problemas de textura se cuantifican normalmente por la ondulación, la longitud de onda y el efecto visual que tienen en los recubrimientos brillantes. Las texturas más pequeñas provocan una reducción del brillo, mientras que las más grandes provocan ondulaciones visibles en la superficie recubierta. Comprender el desarrollo de estas texturas y su relación con los sustratos y las técnicas es fundamental para el control de calidad.

Importancia de la perfilometría para la medición de la textura

A diferencia de los instrumentos 2D tradicionales utilizados para medir la textura del brillo, la medición 3D sin contacto proporciona rápidamente una imagen 3D que se utiliza para comprender las características de la superficie, con la capacidad añadida de investigar rápidamente las áreas de interés. Sin la velocidad y la revisión 3D, un entorno de control de calidad dependería únicamente de información 2D que ofrece poca previsibilidad de toda la superficie. Comprender las texturas en 3D permite seleccionar las mejores medidas de procesamiento y control. Garantizar el control de calidad de dichos parámetros depende en gran medida de una inspección cuantificable, reproducible y confiable. Nanovea 3D sin contacto Perfilómetros Utilizan tecnología confocal cromática para ofrecer la capacidad única de medir los ángulos pronunciados que se encuentran durante las mediciones rápidas. Los perfilómetros Nanovea tienen éxito donde otras técnicas no logran proporcionar datos confiables debido al contacto de la sonda, la variación de la superficie, el ángulo o la reflectividad.

Objetivo de medición

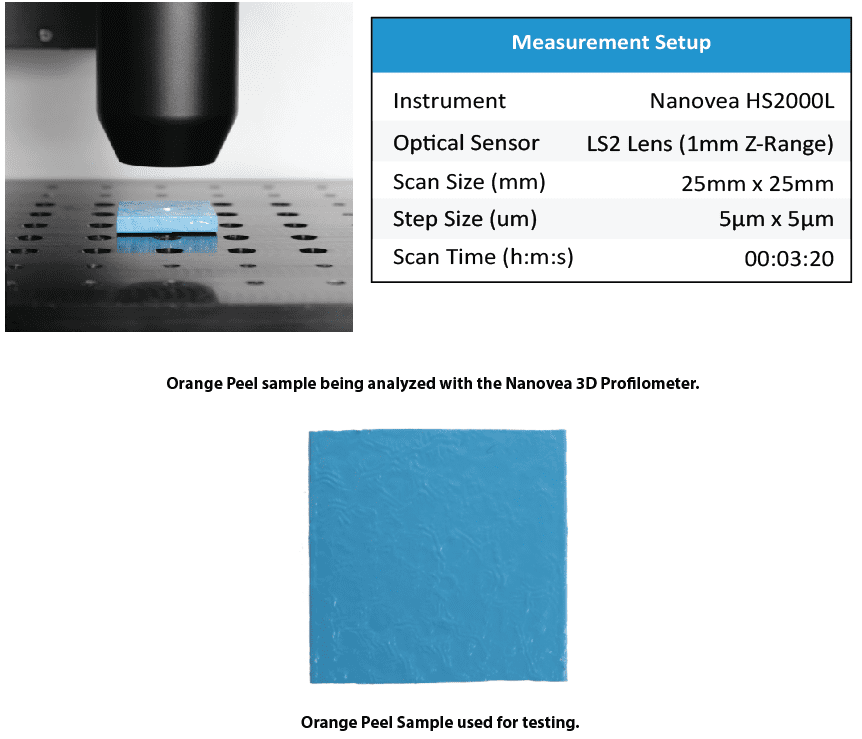

En esta aplicación, el Nanovea HS2000L mide la textura de piel de naranja de una pintura brillante. Hay un sinfín de parámetros superficiales que se calculan automáticamente a partir del escaneo 3D de la superficie. Aquí analizamos una superficie 3D escaneada cuantificando las características de la textura de piel de naranja de la pintura.

El Nanovea HS2000L cuantificó los parámetros de isotropía y altura de la pintura con textura de piel de naranja. La textura de piel de naranja cuantificó la dirección aleatoria del patrón con una isotropía de 94,41 TP3T. Los parámetros de altura cuantifican la textura con una diferencia de altura de 24,84 µm.

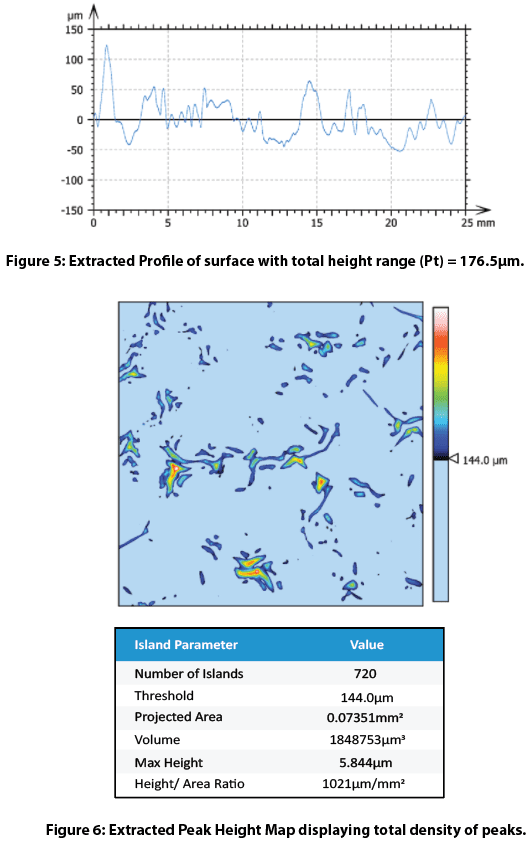

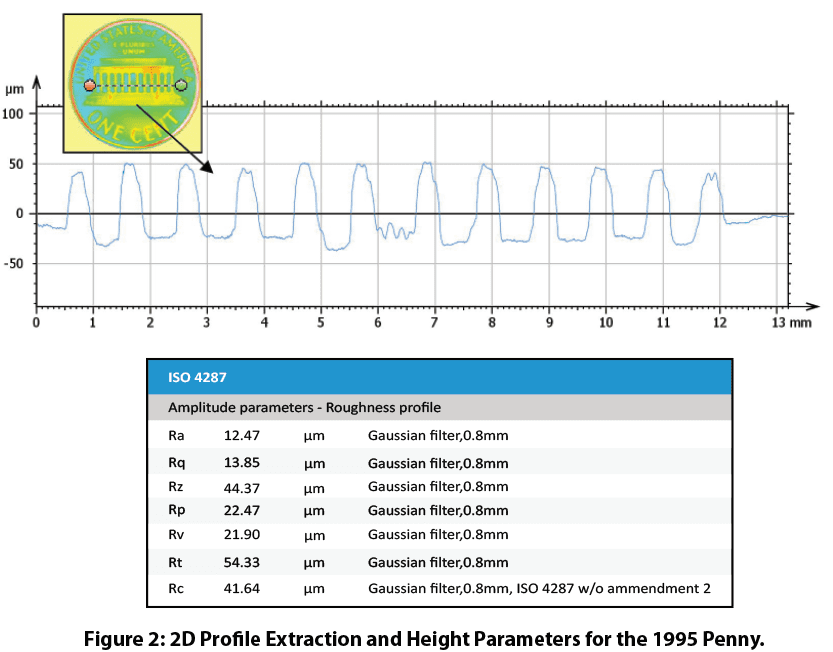

La curva de relación de rodamiento de la figura 4 es una representación gráfica de la distribución de profundidad. Se trata de una función interactiva del software que permite al usuario ver las distribuciones y los porcentajes a diferentes profundidades. El perfil extraído de la figura 5 proporciona valores útiles de rugosidad para la textura de piel de naranja. La extracción de picos por encima de un umbral de 144 micras muestra la textura de piel de naranja. Estos parámetros se pueden ajustar fácilmente a otras áreas o parámetros de interés.

Conclusión

En esta aplicación, el perfilómetro 3D sin contacto Nanovea HS2000L caracteriza con precisión tanto la topografía como los detalles nanométricos de la textura de piel de naranja de la pintura sobre un recubrimiento brillante. Las áreas de interés de las mediciones de superficie 3D se identifican y analizan rápidamente con muchas mediciones útiles (dimensión, rugosidad, textura de acabado, forma, topografía, planitud, deformación, planaridad, volumen, área, altura de escalón, etc.). Las secciones transversales 2D seleccionadas rápidamente proporcionan un conjunto completo de recursos de medición de la superficie sobre la textura brillante. Las áreas de interés especiales se pueden analizar más a fondo con un módulo AFM integrado. La velocidad del perfilómetro 3D Nanovea oscila entre <1 mm/s y 500 mm/s, lo que lo hace adecuado tanto para aplicaciones de investigación como para las necesidades de inspección de alta velocidad. Los perfilómetros 3D Nanovea tienen una amplia gama de configuraciones para adaptarse a su aplicación.

Efecto de la humedad en la tribología del revestimiento de DLC

Importancia de la evaluación del desgaste del DLC en condiciones de humedad

Los recubrimientos de carbono tipo diamante (DLC) poseen propiedades tribológicas mejoradas, concretamente una excelente resistencia al desgaste y un coeficiente de fricción (COF) muy bajo. Los recubrimientos de DLC imprimen características de diamante cuando se depositan sobre distintos materiales. Las propiedades tribo-mecánicas favorables hacen que los recubrimientos de DLC sean preferibles en diversas aplicaciones industriales, como piezas aeroespaciales, hojas de afeitar, herramientas de corte de metal, cojinetes, motores de motocicletas e implantes médicos.

Los revestimientos de DLC presentan un COF muy bajo (inferior a 0,1) frente a bolas de acero en condiciones de alto vacío y en seco.12. Sin embargo, los recubrimientos de DLC son sensibles a los cambios de las condiciones ambientales, en particular a la humedad relativa (HR)3. Los entornos con alta humedad y concentración de oxígeno pueden provocar un aumento significativo del COF4. La evaluación fiable del desgaste en condiciones de humedad controlada simula las condiciones ambientales realistas de los revestimientos de DLC para aplicaciones tribológicas. Los usuarios seleccionan los mejores revestimientos de DLC para las aplicaciones deseadas mediante una comparación adecuada.

de los comportamientos de desgaste del DLC expuesto a diferentes humedades.

Objetivo de medición

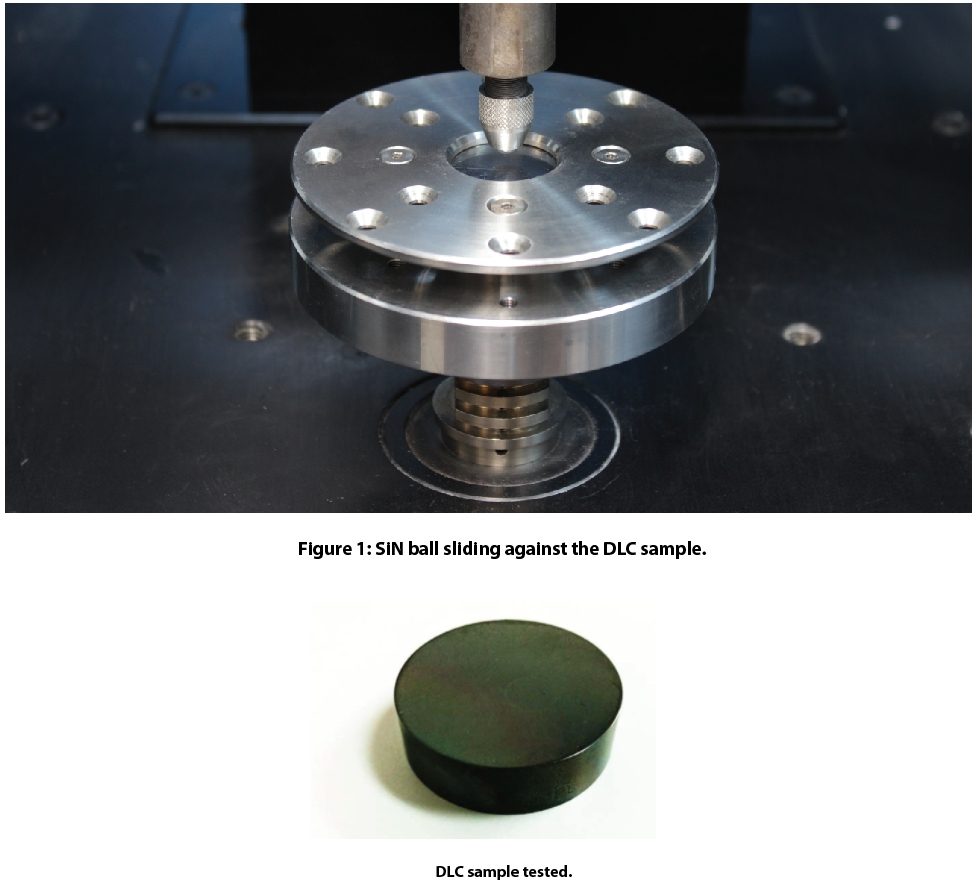

Este estudio muestra la tecnología Nanovea Tribómetro equipado con un controlador de humedad es la herramienta ideal para investigar el comportamiento de desgaste de los recubrimientos de DLC a distintas humedades relativas.

Procedimiento de ensayo

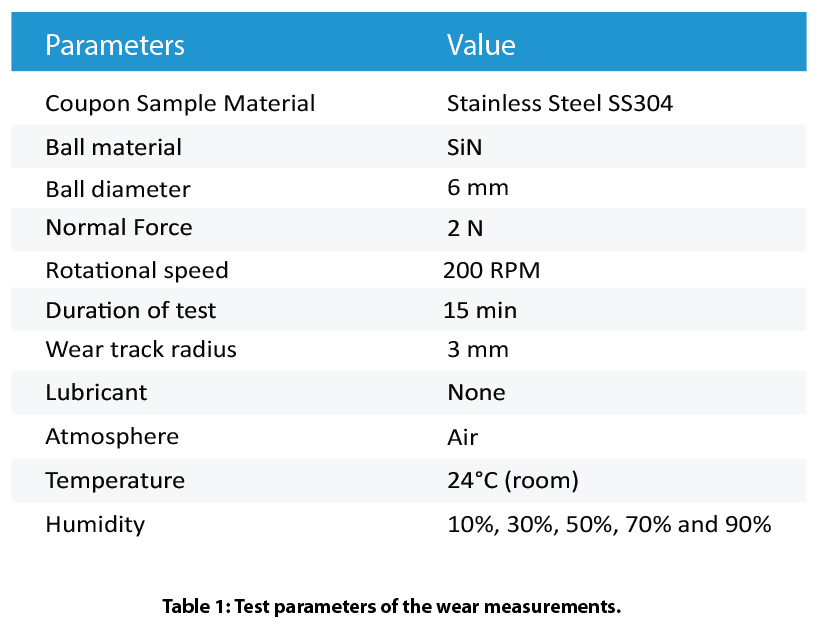

La resistencia a la fricción y al desgaste de los recubrimientos de DLC se evaluó con el tribómetro Nanovea. Los parámetros de ensayo se resumen en la Tabla 1. Un controlador de humedad acoplado a la tribocámara controló con precisión la humedad relativa (HR) con una exactitud de ±1%. Las huellas de desgaste en los recubrimientos de DLC y las cicatrices de desgaste en las bolas de SiN se examinaron con un microscopio óptico después de las pruebas.

Nota: Se puede aplicar cualquier material de bola sólida para simular el rendimiento de acoplamiento de diferentes materiales en condiciones ambientales como en lubricante o alta temperatura.

Resultados y debate

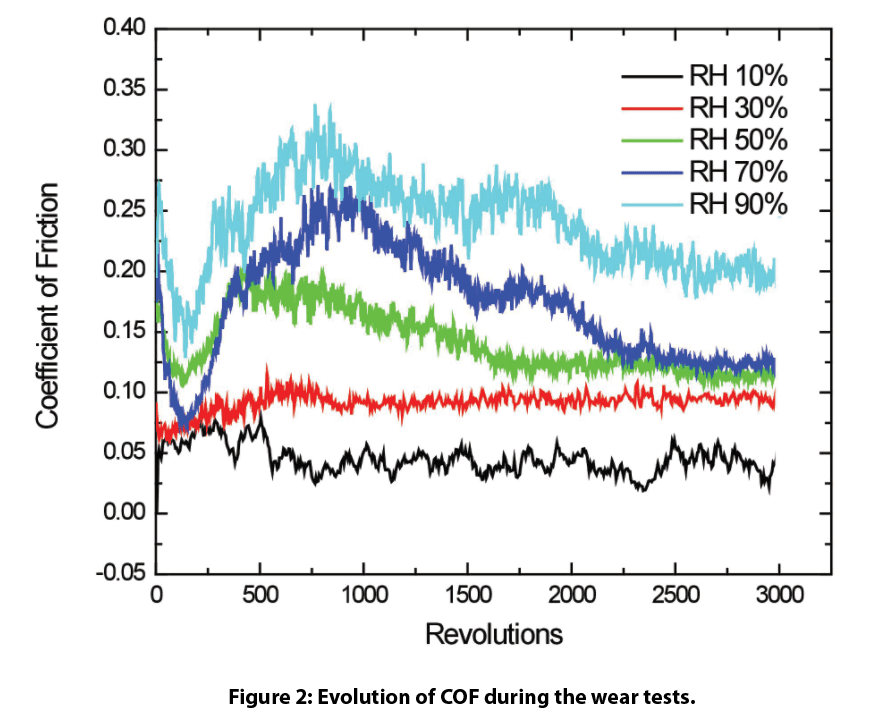

Los recubrimientos de DLC son excelentes para aplicaciones tribológicas debido a su baja fricción y a su mayor resistencia al desgaste. La fricción del recubrimiento de DLC presenta un comportamiento dependiente de la humedad, como se muestra en la figura 2. El recubrimiento de DLC muestra un COF muy bajo de ~0,05 durante todo el ensayo de desgaste en condiciones relativamente secas (10% HR). El recubrimiento de DLC muestra un COF constante de ~0,1 durante la prueba a medida que la HR aumenta hasta 30%. La fase inicial de rodaje del COF se observa en las primeras 2000 revoluciones cuando la HR aumenta por encima de 50%. El revestimiento de DLC muestra un COF máximo de ~0,20, ~0,26 y ~0,33 en HR de 50, 70 y 90%, respectivamente. Tras el periodo de rodaje, el COF del revestimiento de DLC se mantiene constante en ~0,11, 0,13 y 0,20 con HR de 50, 70 y 90%, respectivamente.

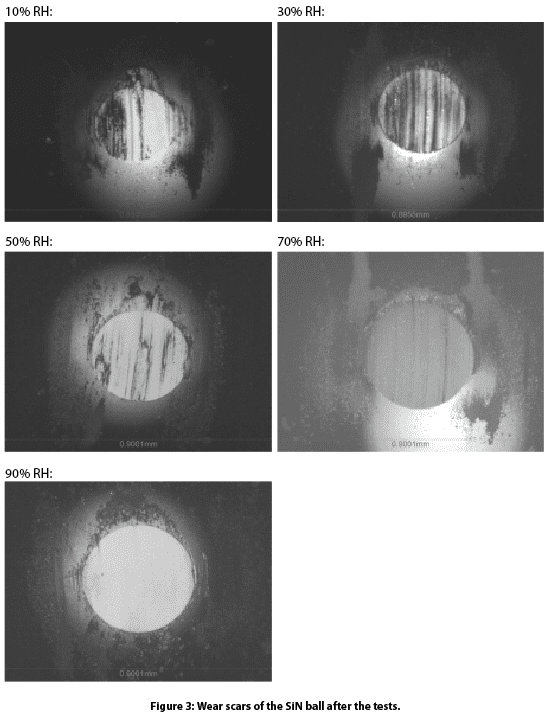

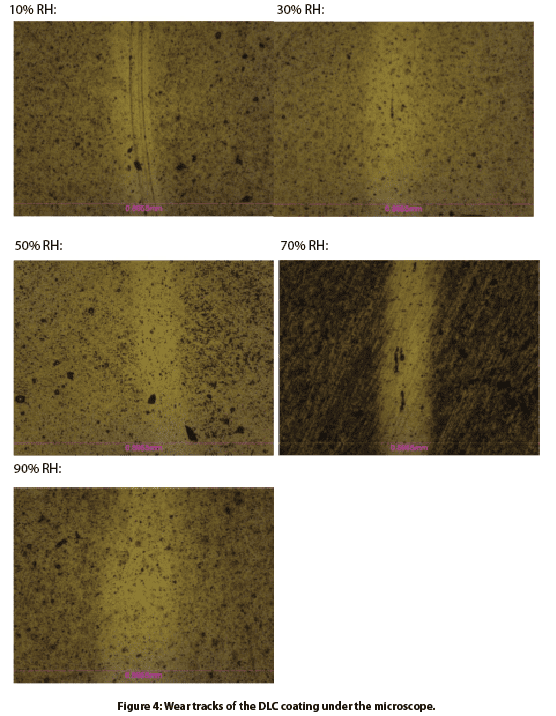

La figura 3 compara las cicatrices de desgaste de las bolas de SiN y la figura 4 compara las huellas de desgaste del recubrimiento de DLC tras las pruebas de desgaste. El diámetro de la cicatriz de desgaste era menor cuando el recubrimiento de DLC se exponía a un entorno con baja humedad. La capa de DLC transferida se acumula en la superficie de la bola de SiN durante el proceso de deslizamiento repetitivo en la superficie de contacto. En esta fase, el recubrimiento de DLC se desliza contra su propia capa de transferencia, que actúa como un lubricante eficaz para facilitar el movimiento relativo y frenar la pérdida de masa adicional causada por la deformación por cizallamiento. Se observa una película de transferencia en la cicatriz de desgaste de la bola de SiN en entornos de baja HR (por ejemplo, 10% y 30%), lo que da lugar a un proceso de desgaste desacelerado de la bola. Este proceso de desgaste se refleja en la morfología de la pista de desgaste del recubrimiento de DLC, como se muestra en la figura 4. El recubrimiento de DLC muestra una pista de desgaste más pequeña en ambientes secos, debido a la formación de una película de transferencia de DLC estable en la interfaz de contacto que reduce significativamente la fricción y la tasa de desgaste.

Conclusión

La humedad desempeña un papel fundamental en el rendimiento tribológico de los recubrimientos de DLC. El recubrimiento de DLC posee una resistencia al desgaste significativamente mejorada y una baja fricción superior en condiciones secas debido a la formación de una capa grafítica estable transferida a la contraparte deslizante (una bola de SiN en este estudio). El recubrimiento de DLC se desliza contra su propia capa de transferencia, que actúa como un lubricante eficaz para facilitar el movimiento relativo y frenar la pérdida de masa adicional causada por la deformación por cizallamiento. No se observa una película en la bola de SiN con el aumento de la humedad relativa, lo que conduce a un aumento de la tasa de desgaste en la bola de SiN y el recubrimiento de DLC.

El tribómetro Nanovea ofrece pruebas repetibles de desgaste y fricción mediante modos rotativos y lineales conformes a las normas ISO y ASTM, con módulos opcionales de humedad disponibles en un sistema preintegrado. Permite a los usuarios simular el entorno de trabajo a diferentes humedades, proporcionando a los usuarios una herramienta ideal para evaluar cuantitativamente los comportamientos tribológicos de los materiales en diferentes condiciones de trabajo.

Más información sobre el tribómetro Nanovea y el servicio de laboratorio

1 C. Donnet, Surf. Coat. Technol. 100-101 (1998) 180.

2 K. Miyoshi, B. Pohlchuck, K.W. Street, J.S. Zabinski, J.H. Sanders, A.A. Voevodin, R.L.C. Wu, Wear 225-229 (1999) 65.- K. Miyoshi.

3 R. Gilmore, R. Hauert, Surf. Coat. Technol. 133-134 (2000) 437.

4 R. Memming, H.J. Tolle, P.E. Wierenga, Thin Solid Coatings 143 (1986) 31

Análisis tridimensional de la superficie de un centavo con perfilometría sin contacto

Importancia de la perfilometría sin contacto para monedas

La moneda tiene un gran valor en la sociedad moderna, ya que se utiliza para intercambiar bienes y servicios. Las monedas y los billetes circulan por las manos de muchas personas. La transferencia constante de moneda física provoca deformaciones en la superficie. Nanovea 3D Perfilómetro escanea la topografía de monedas acuñadas en diferentes años para investigar las diferencias en la superficie.

Las características de las monedas son fácilmente reconocibles para el público en general, ya que son objetos comunes. Una moneda de un centavo es ideal para presentar la potencia del software de análisis avanzado de superficies de Nanovea: Mountains 3D. Los datos de superficie recopilados con nuestro perfilómetro 3D permiten realizar análisis de alto nivel sobre geometrías complejas con sustracción de superficies y extracción de contornos 2D. La sustracción de superficies con una máscara, un sello o un molde controlados compara la calidad de los procesos de fabricación, mientras que la extracción de contornos identifica las tolerancias con análisis dimensionales. El perfilómetro 3D y el software Mountains 3D de Nanovea investigan la topografía submicrométrica de objetos aparentemente simples, como las monedas de un centavo.

Objetivo de medición

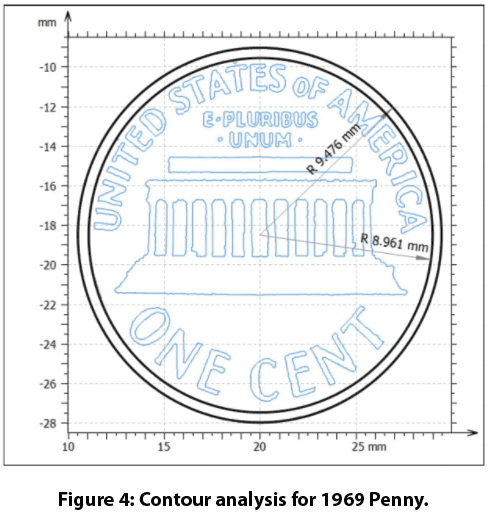

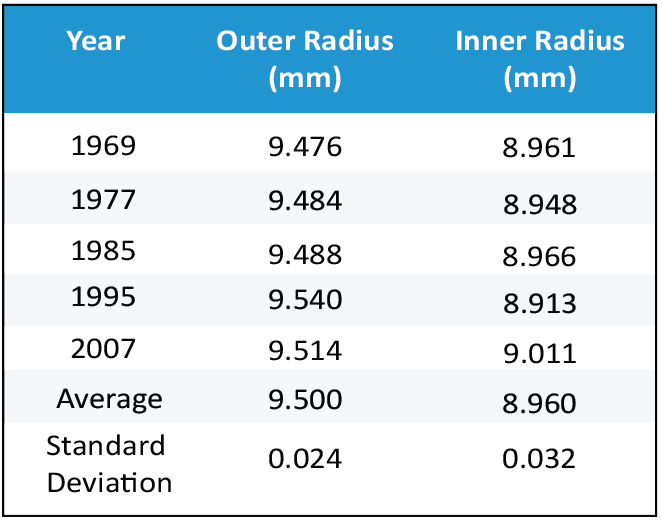

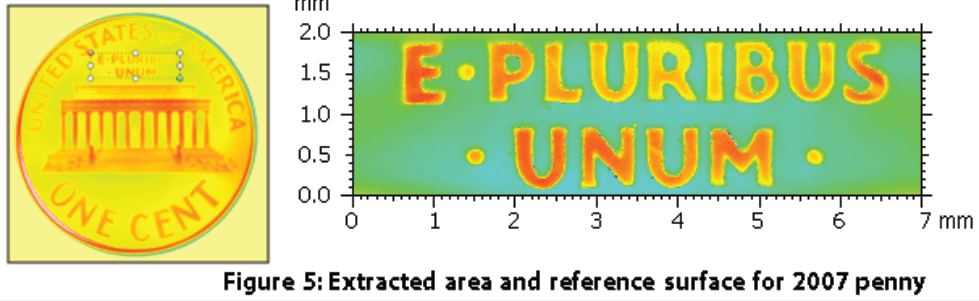

Se escaneó toda la superficie superior de cinco monedas de un centavo utilizando el sensor lineal de alta velocidad de Nanovea. Se midieron los radios interior y exterior de cada moneda utilizando el software de análisis avanzado Mountains. Se cuantificó la deformación de la superficie mediante la extracción de cada superficie de moneda en un área de interés con sustracción directa de la superficie.

Resultados y debate

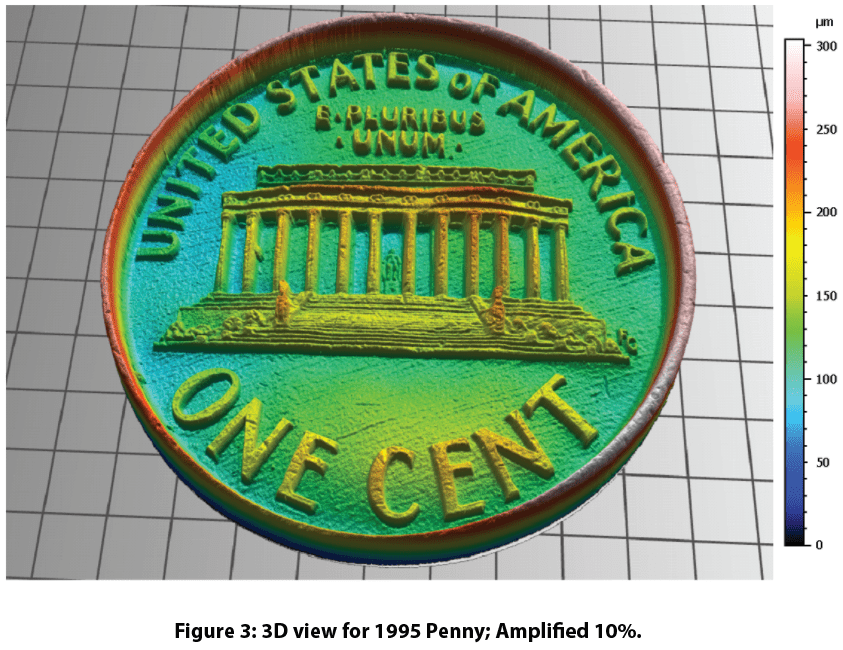

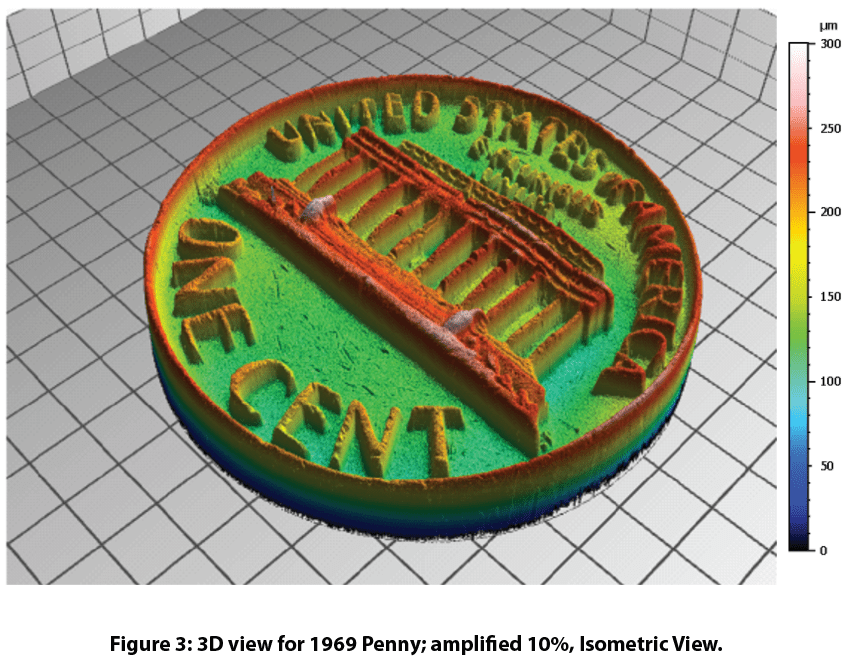

Superficie 3D

El perfilómetro Nanovea HS2000 tardó solo 24 segundos en escanear 4 millones de puntos en un área de 20 mm x 20 mm con un tamaño de paso de 10 um x 10 um para adquirir la superficie de un centavo. A continuación se muestra un mapa de altura y una visualización en 3D del escaneo. La vista en 3D muestra la capacidad del sensor de alta velocidad para captar pequeños detalles imperceptibles a simple vista. Se pueden ver muchos pequeños arañazos en la superficie de la moneda. Se investigan la textura y la rugosidad de la moneda que se observan en la vista en 3D.

Se extrajeron los contornos de la moneda y, mediante un análisis dimensional, se obtuvieron los diámetros interior y exterior del borde. El radio exterior promedió 9,500 mm ± 0,024, mientras que el radio interior promedió 8,960 mm ± 0,032. Otros análisis dimensionales que Mountains 3D puede realizar con fuentes de datos 2D y 3D son mediciones de distancia, altura de escalón, planitud y cálculos de ángulos.

La figura 5 muestra el área de interés para el análisis de sustracción de superficie. Se utilizó la moneda de un centavo de 2007 como superficie de referencia para las cuatro monedas más antiguas. La sustracción de superficie de la moneda de un centavo de 2007 muestra diferencias entre las monedas con agujeros/picos. La diferencia total de volumen de superficie se obtiene sumando los volúmenes de los agujeros/picos. El error RMS se refiere a la precisión con la que coinciden las superficies de las monedas entre sí.

Conclusión

El escáner de alta velocidad HS2000L de Nanovea escaneó cinco monedas de cinco centavos acuñadas en diferentes años. El software Mountains 3D comparó las superficies de cada moneda utilizando la extracción de contornos, el análisis dimensional y la sustracción de superficies. El análisis define claramente el radio interior y exterior entre las monedas de un centavo, al tiempo que compara directamente las diferencias en las características de la superficie. Gracias a la capacidad del perfilómetro 3D de Nanovea para medir cualquier superficie con una resolución a nivel nanométrico, combinada con las capacidades de análisis de Mountains 3D, las posibles aplicaciones en investigación y control de calidad son infinitas.

AHORA, HABLEMOS DE SU SOLICITUD

Acabado dimensional y superficial de los tubos poliméricos

Importancia del análisis dimensional y superficial de los tubos poliméricos

Los tubos fabricados con material polimérico se utilizan habitualmente en muchos sectores, como el automovilístico, el médico, el eléctrico y muchos otros. En este estudio, se analizaron catéteres médicos fabricados con diferentes materiales poliméricos utilizando Nanovea. Perfilómetro 3D sin contacto para medir la rugosidad, la morfología y las dimensiones de la superficie. La rugosidad de la superficie es crucial para los catéteres, ya que muchos de los problemas que estos presentan, como infecciones, traumatismos físicos e inflamaciones, pueden estar relacionados con la superficie del catéter. Las propiedades mecánicas, como el coeficiente de fricción, también pueden estudiarse observando las propiedades de la superficie. Estos datos cuantificables pueden obtenerse para garantizar que el catéter pueda utilizarse en aplicaciones médicas.

En comparación con la microscopía óptica y la microscopía electrónica, la perfilometría 3D sin contacto que utiliza cromatismo axial es muy recomendable para caracterizar las superficies de los catéteres debido a su capacidad para medir ángulos/curvaturas, medir superficies de materiales a pesar de su transparencia o reflectividad, la mínima preparación de muestras y su naturaleza no invasiva. A diferencia de la microscopía óptica convencional, se puede obtener la altura de la superficie y utilizarla para el análisis computacional; por ejemplo, para encontrar dimensiones y eliminar formas para determinar la rugosidad de la superficie. Al requerir poca preparación de la muestra, en contraste con la microscopía electrónica, y al ser de naturaleza no invasiva, también permite una rápida recopilación de datos sin temor a la contaminación y los errores derivados de la preparación de la muestra.

Objetivo de medición

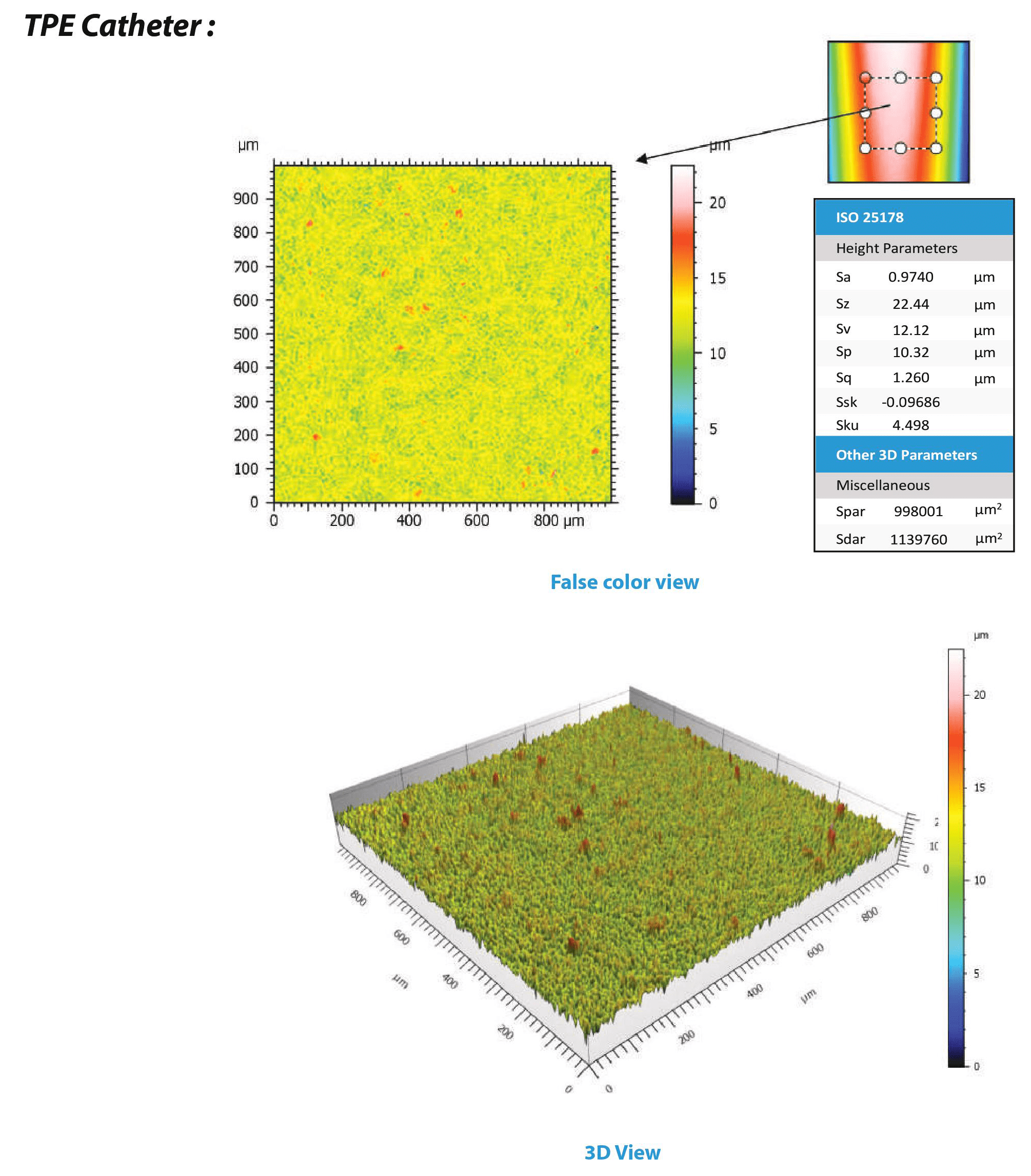

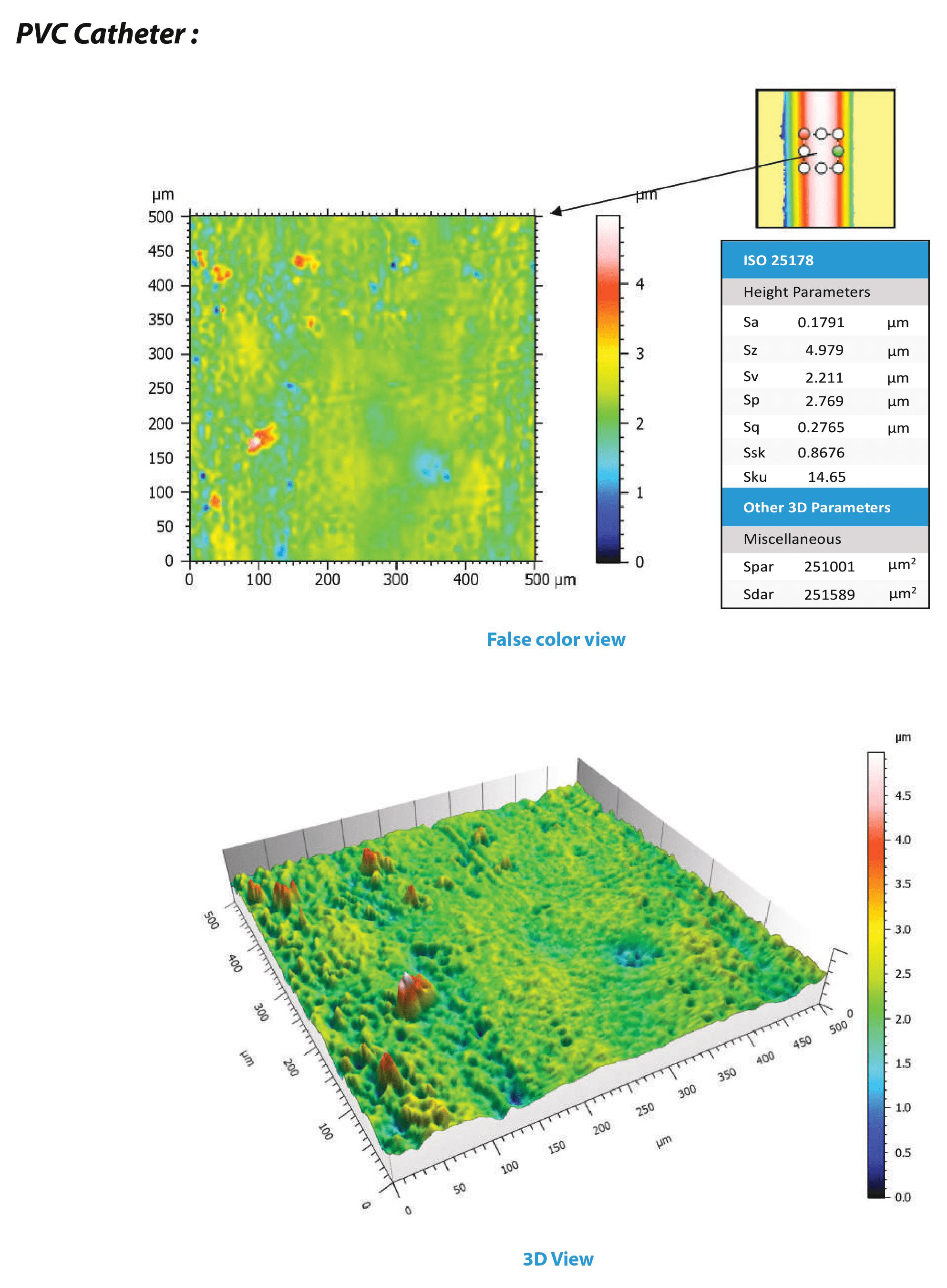

En esta aplicación, se utiliza el perfilómetro sin contacto Nanovea 3D para escanear la superficie de dos catéteres: uno fabricado en TPE (elastómero termoplástico) y otro en PVC (cloruro de polivinilo). Se obtendrán y compararán los parámetros de morfología, dimensión radial y altura de los dos catéteres.

Resultados y debate

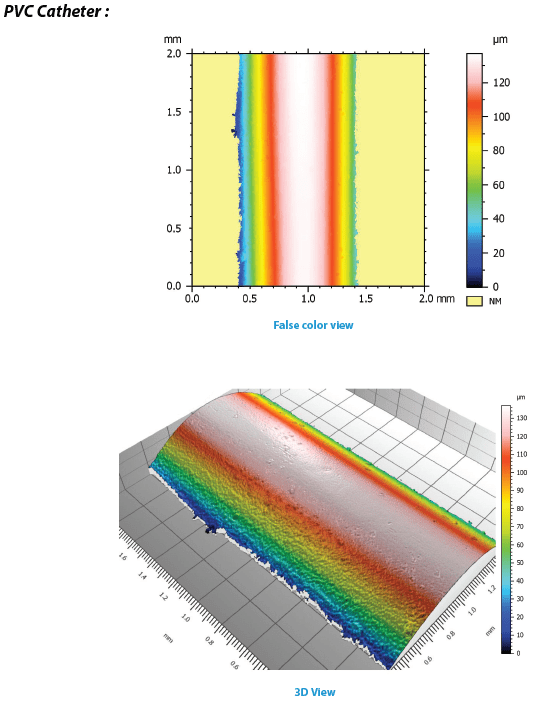

Superficie 3D

A pesar de la curvatura de los tubos poliméricos, el perfilómetro sin contacto Nanovea 3D puede escanear la superficie de los catéteres. A partir del escaneo realizado, se puede obtener una imagen 3D para una inspección visual rápida y directa de la superficie.

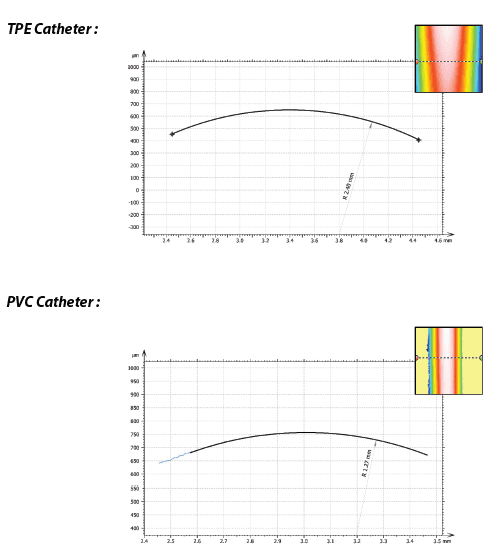

La dimensión radial exterior se obtuvo extrayendo un perfil del escaneo original y ajustando un arco al perfil. Esto demuestra la capacidad del perfilómetro 3D sin contacto para realizar análisis dimensionales rápidos para aplicaciones de control de calidad. También se pueden obtener fácilmente múltiples perfiles a lo largo de la longitud del catéter.

La dimensión radial exterior se obtuvo extrayendo un perfil del escaneo original y ajustando un arco al perfil. Esto demuestra la capacidad del perfilómetro 3D sin contacto para realizar análisis dimensionales rápidos para aplicaciones de control de calidad. También se pueden obtener fácilmente múltiples perfiles a lo largo de la longitud del catéter.

Conclusión

En esta aplicación, hemos mostrado cómo se puede utilizar el perfilómetro sin contacto Nanovea 3D para caracterizar tubos poliméricos. En concreto, se obtuvieron datos de metrología superficial, dimensiones radiales y rugosidad superficial de catéteres médicos. Se determinó que el radio exterior del catéter de TPE era de 2,40 mm, mientras que el del catéter de PVC era de 1,27 mm. Se observó que la superficie del catéter de TPE era más rugosa que la del catéter de PVC. El Sa del TPE era de 0,9740 µm, en comparación con los 0,1791 µm del PVC. Aunque para esta aplicación se utilizaron catéteres médicos, la perfilometría 3D sin contacto también se puede aplicar a una gran variedad de superficies. Los datos y cálculos que se pueden obtener no se limitan a los que se muestran.

AHORA, HABLEMOS DE SU SOLICITUD

Evaluación de la dureza dental mediante nanoindentación

Importancia de la nanoindentación para los biomateriales

Con muchas pruebas mecánicas tradicionales (dureza, adhesión, compresión, perforación, límite elástico, etc.), los entornos actuales de control de calidad con materiales sensibles avanzados, desde geles hasta materiales frágiles, requieren ahora un mayor control de la precisión y la fiabilidad. Los instrumentos mecánicos tradicionales no proporcionan el control de carga sensible y la resolución necesarios, ya que están diseñados para utilizarse con materiales a granel. A medida que el tamaño de los materiales sometidos a prueba cobró mayor interés, se desarrolló Nanoindentación proporcionó un método confiable para obtener información mecánica esencial en superficies más pequeñas, como la investigación que se realiza con biomateriales. Los retos específicos asociados a los biomateriales han requerido el desarrollo de ensayos mecánicos capaces de controlar con precisión la carga en materiales extremadamente blandos o frágiles. Además, se necesitan múltiples instrumentos para realizar diversos ensayos mecánicos que ahora pueden llevarse a cabo en un solo sistema. La nanoindentación proporciona una amplia gama de mediciones con una resolución precisa a cargas controladas a nanoescala para aplicaciones sensibles.

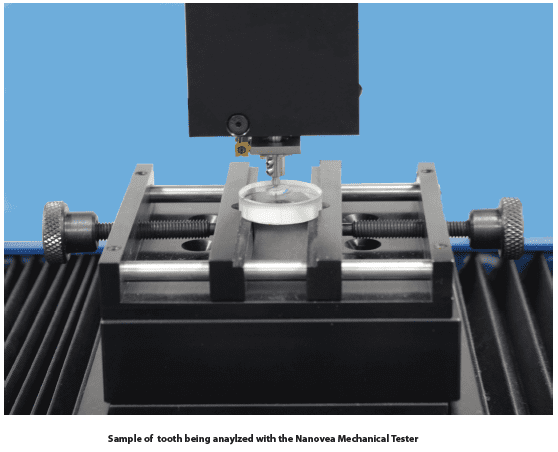

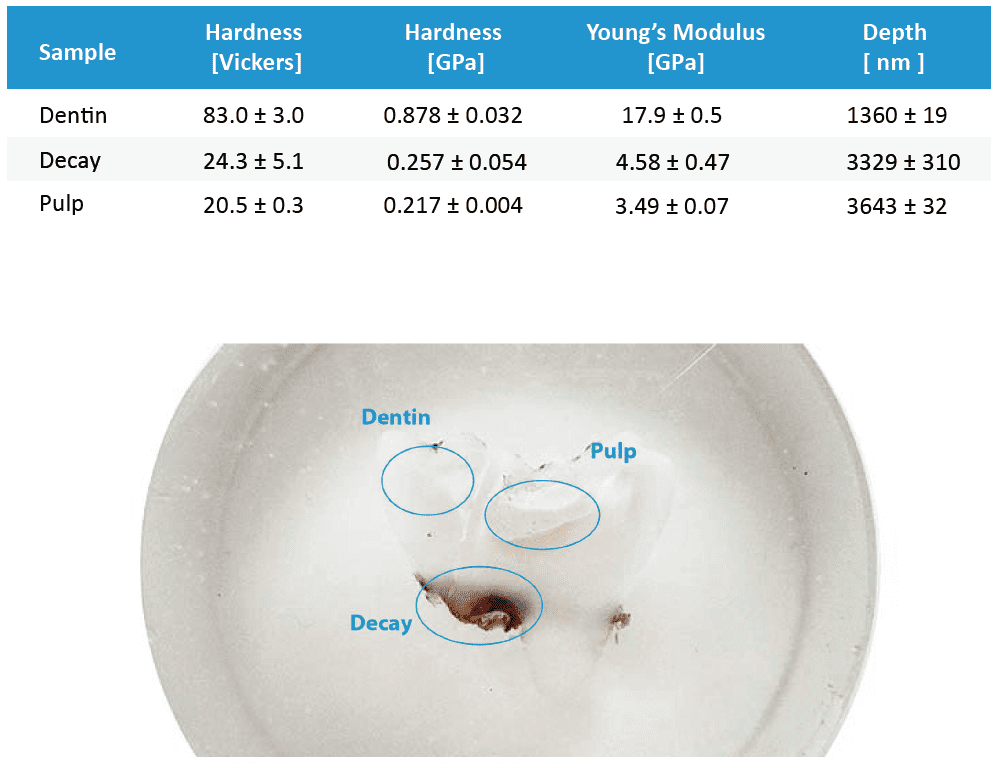

Objetivo de medición

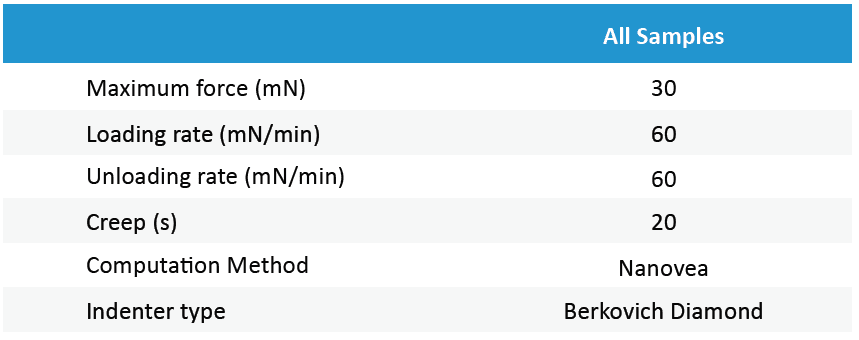

En esta aplicación, Nanovea Comprobador mecánico, en modo nanoindentación, se utiliza para estudiar la dureza y el módulo elástico de la dentina, la caries y la pulpa de un diente. El aspecto más crítico de las pruebas de nanoindentación es asegurar la muestra. En este caso, tomamos un diente cortado y lo montamos con epoxi, dejando expuestas las tres áreas de interés para la prueba.

Resultados y debate

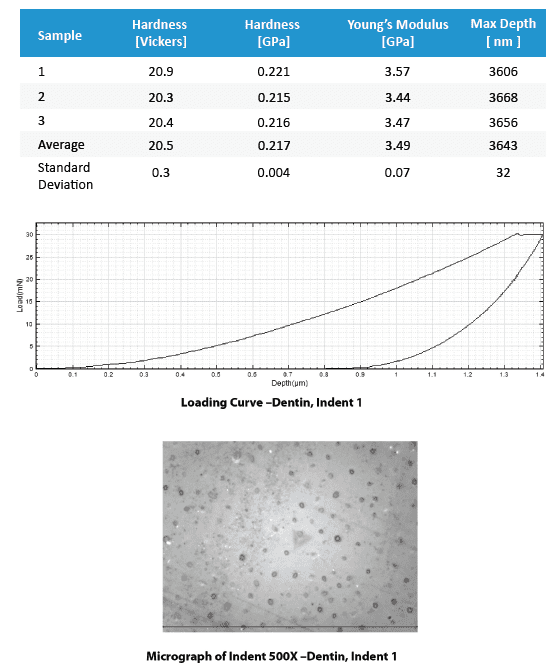

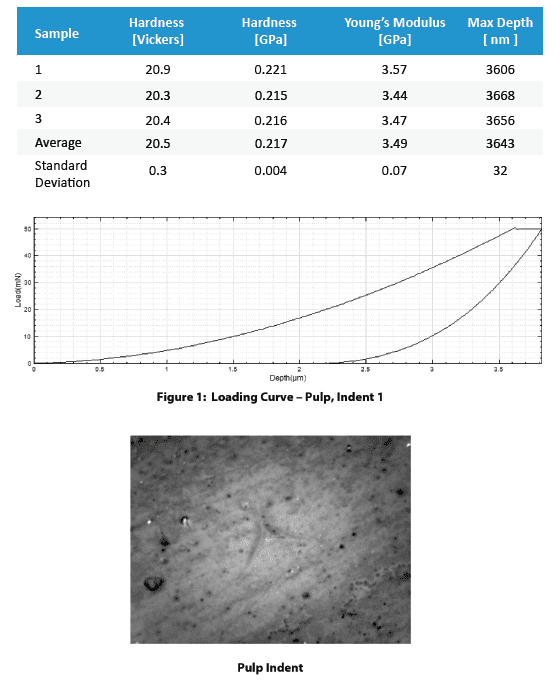

Esta sección incluye una tabla resumen que compara los principales resultados numéricos de las diferentes muestras, seguida de la lista completa de resultados, incluyendo cada indentación realizada, acompañada de micrografías de la indentación, cuando están disponibles. Estos resultados completos presentan los valores medidos de dureza y módulo de Young como la profundidad de penetración con sus promedios y desviaciones estándar. Debe tenerse en cuenta que pueden producirse grandes variaciones en los resultados en caso de que la rugosidad de la superficie se encuentre en el mismo rango de tamaño que la indentación.

Cuadro resumen de los principales resultados numéricos:

Conclusión

En conclusión, hemos demostrado cómo el Nanovea Mechanical Tester, en modo nanoindentación, proporciona una medición precisa de las propiedades mecánicas de un diente. Los datos pueden utilizarse en el desarrollo de empastes que se adapten mejor a las características mecánicas de un diente real. La capacidad de posicionamiento del Nanovea Mechanical Tester permite realizar un mapeo completo de la dureza de los dientes en las distintas zonas.

Utilizando el mismo sistema, es posible probar la resistencia a la fractura del material dental con cargas más elevadas, de hasta 200 N. Se puede realizar una prueba de carga multiciclo en materiales más porosos para evaluar el nivel de elasticidad restante. El uso de una punta de diamante cilíndrica plana puede proporcionar información sobre el límite elástico en cada zona. Además, con el “análisis mecánico dinámico” (DMA), se pueden evaluar las propiedades viscoelásticas, incluidos los módulos de pérdida y almacenamiento.

El nanomódulo Nanovea es ideal para estas pruebas porque utiliza una respuesta de retroalimentación única para controlar con precisión la carga aplicada. Gracias a ello, el nanomódulo también se puede utilizar para realizar pruebas precisas de nanoarañazos. El estudio de la resistencia al rayado y al desgaste de los materiales dentales y de obturación aumenta la utilidad general del probador mecánico. El uso de una punta afilada de 2 micras para comparar cuantitativamente el desgaste de los materiales de obturación permitirá predecir mejor el comportamiento en aplicaciones reales. Las pruebas de desgaste multipaso o de desgaste rotativo directo también son pruebas comunes que proporcionan información importante sobre la viabilidad a largo plazo.

AHORA, HABLEMOS DE SU SOLICITUD

Evaluación de la fricción a velocidades extremadamente bajas

Importancia de la evaluación de la fricción a bajas velocidades

La fricción es la fuerza que se opone al movimiento relativo de superficies sólidas que se deslizan unas contra otras. Cuando se produce el movimiento relativo de estas dos superficies en contacto, la fricción en la interfaz convierte la energía cinética en calor. Este proceso también puede provocar el desgaste del material y, por lo tanto, la degradación del rendimiento de las piezas en uso.

Con un gran índice de elasticidad, alta resistencia, así como excelentes propiedades impermeables y resistencia al desgaste, el caucho se utiliza ampliamente en una gran variedad de aplicaciones y productos en los que la fricción juega un papel importante, como los neumáticos de automóvil, las escobillas limpiaparabrisas, las suelas de zapatos y muchos otros. Dependiendo de la naturaleza y los requisitos de estas aplicaciones, se requiere una fricción alta o baja con respecto a diferentes materiales. Por consiguiente, resulta fundamental realizar una medición controlada y fiable de la fricción del caucho con respecto a diversas superficies.

Objetivo de medición

El coeficiente de fricción (COF) del caucho con respecto a diferentes materiales se mide de forma controlada y supervisada utilizando el Nanovea. Tribómetro. En este estudio, nos gustaría mostrar la capacidad del tribómetro Nanovea para medir el coeficiente de fricción (COF) de diferentes materiales a velocidades extremadamente bajas.

Resultados y debate

El coeficiente de fricción (COF) de bolas de caucho (6 mm de diámetro, RubberMill) sobre tres materiales (acero inoxidable SS 316, Cu 110 y acrílico opcional) se evaluó mediante el tribómetro Nanovea. Las muestras metálicas sometidas a prueba se pulieron mecánicamente hasta obtener un acabado superficial similar al de un espejo antes de la medición. La ligera deformación de la bola de caucho bajo la carga normal aplicada creó un área de contacto, lo que también ayuda a reducir el impacto de las asperezas o la falta de homogeneidad del acabado de la superficie de la muestra en las mediciones del COF. Los parámetros de la prueba se resumen en la tabla 1.

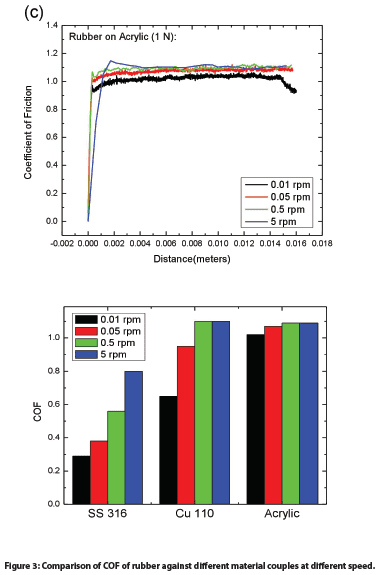

El COF de una pelota de goma contra diferentes materiales a cuatro velocidades diferentes se muestra en la figura 2, y los COF medios calculados automáticamente por el software se resumen y comparan en la figura 3. Es interesante observar que las muestras metálicas (SS 316 y Cu 110) muestran un aumento significativo de los COF a medida que la velocidad de rotación aumenta desde un valor muy bajo de 0,01 rpm hasta 5 rpm: el valor del COF del par caucho/SS 316 aumenta de 0,29 a 0,8, y de 0,65 a 1,1 para el par caucho/Cu 110. Este hallazgo concuerda con los resultados comunicados por varios laboratorios. Tal y como propone Grosch4 La fricción del caucho viene determinada principalmente por dos mecanismos: (1) la adhesión entre el caucho y el otro material, y (2) las pérdidas de energía debidas a la deformación del caucho causada por las asperezas de la superficie. Schallamach5 Se observaron ondas de desprendimiento del caucho del material de contraposición a lo largo de la interfaz entre las esferas de caucho blando y una superficie dura. La fuerza necesaria para que el caucho se desprenda de la superficie del sustrato y la velocidad de las ondas de desprendimiento pueden explicar las diferentes fricciones observadas a distintas velocidades durante la prueba.

En comparación, la combinación de caucho y acrílico presenta un alto COF a diferentes velocidades de rotación. El valor del COF aumenta ligeramente de ~ 1,02 a ~ 1,09 a medida que la velocidad de rotación aumenta de 0,01 rpm a 5 rpm. Es posible que este alto COF se deba a una unión química local más fuerte en la superficie de contacto formada durante las pruebas.

Conclusión

En este estudio, demostramos que, a velocidades extremadamente bajas, el caucho presenta un comportamiento de fricción peculiar: su fricción contra una superficie dura aumenta con el incremento de la velocidad del movimiento relativo. El caucho muestra una fricción diferente cuando se desliza sobre distintos materiales. El tribómetro Nanovea puede evaluar las propiedades de fricción de los materiales de forma controlada y supervisada a diferentes velocidades, lo que permite a los usuarios mejorar su comprensión fundamental del mecanismo de fricción de los materiales y seleccionar el mejor par de materiales para aplicaciones de ingeniería tribológica específicas.

El tribómetro Nanovea ofrece pruebas de desgaste y fricción precisas y repetibles utilizando modos rotativos y lineales que cumplen con las normas ISO y ASTM, con módulos opcionales de desgaste a alta temperatura, lubricación y tribocorrosión disponibles en un sistema preintegrado. Es capaz de controlar la etapa rotativa a velocidades extremadamente bajas, de hasta 0,01 rpm, y supervisar la evolución de la fricción in situ. La inigualable gama de Nanovea es una solución ideal para determinar todas las propiedades tribológicas de recubrimientos, películas y sustratos finos o gruesos, blandos o duros.

AHORA, HABLEMOS DE SU SOLICITUD

Tribología de polímeros

Introducción

Los polímeros se han utilizado ampliamente en una gran variedad de aplicaciones y se han convertido en una parte indispensable de la vida cotidiana. Los polímeros naturales, como el ámbar, la seda y el caucho natural, han desempeñado un papel esencial en la historia de la humanidad. El proceso de fabricación de los polímeros sintéticos puede optimizarse para conseguir propiedades físicas únicas, como resistencia, viscoelasticidad, autolubricación y muchas otras.

Importancia del desgaste y la fricción de los polímeros

Los polímeros se utilizan habitualmente en aplicaciones tribológicas, como neumáticos, rodamientos y cintas transportadoras.

Se producen diferentes mecanismos de desgaste en función de las propiedades mecánicas del polímero, las condiciones de contacto y las propiedades de los residuos o la película de transferencia que se forma durante el proceso de desgaste. Para garantizar que los polímeros posean una resistencia al desgaste suficiente en las condiciones de servicio, es necesaria una evaluación tribológica fiable y cuantificable. La evaluación tribológica nos permite comparar cuantitativamente los comportamientos de desgaste de diferentes polímeros de forma controlada y supervisada para seleccionar el material candidato para la aplicación deseada.

El tribómetro Nanovea ofrece pruebas repetibles de desgaste y fricción utilizando modos rotativos y lineales que cumplen con las normas ISO y ASTM, con módulos opcionales de desgaste a alta temperatura y lubricación disponibles en un sistema preintegrado. Esta gama inigualable permite a los usuarios simular los diferentes entornos de trabajo de los polímeros, incluyendo tensión concentrada, desgaste y alta temperatura, etc.

OBJETIVO DE MEDICIÓN

En este estudio, demostramos que Nanovea Tribómetro es una herramienta ideal para comparar la fricción y la resistencia al desgaste de diferentes polímeros de una manera bien controlada y cuantitativa.

PROCEDIMIENTO DE PRUEBA

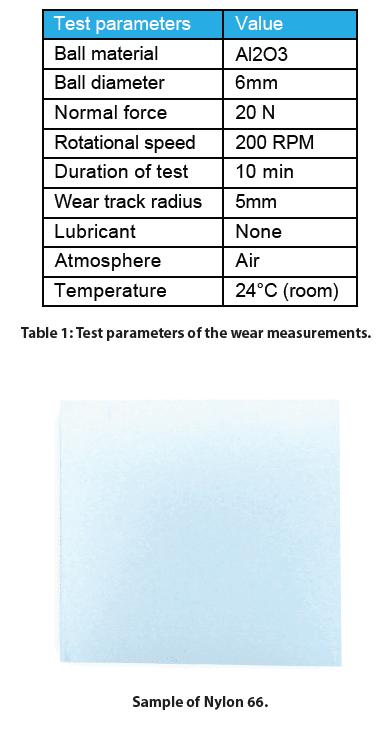

El coeficiente de fricción (COF) y la resistencia al desgaste de diferentes polímeros comunes se evaluaron mediante el tribómetro Nanovea. Se utilizó una bola de Al2O3 como material de contacto (pasador, muestra estática). Las marcas de desgaste en los polímeros (muestras dinámicas giratorias) se midieron utilizando un perfilómetro 3D sin contacto y un microscopio óptico una vez concluidas las pruebas. Cabe señalar que, como opción, se puede utilizar un sensor endoscópico sin contacto para medir la profundidad a la que el pasador penetra en la muestra dinámica durante una prueba de desgaste. Los parámetros de la prueba se resumen en la tabla 1. La tasa de desgaste, K, se evaluó utilizando la fórmula K=Vl(Fxs), donde V es el volumen desgastado, F es la carga normal y s es la distancia de deslizamiento.

Tenga en cuenta que en este estudio se utilizaron bolas de Al2O3 como material de contraste. Se puede sustituir por cualquier material sólido para simular con mayor precisión el rendimiento de dos muestras en condiciones de aplicación reales.

RESULTADOS Y DISCUSIÓN

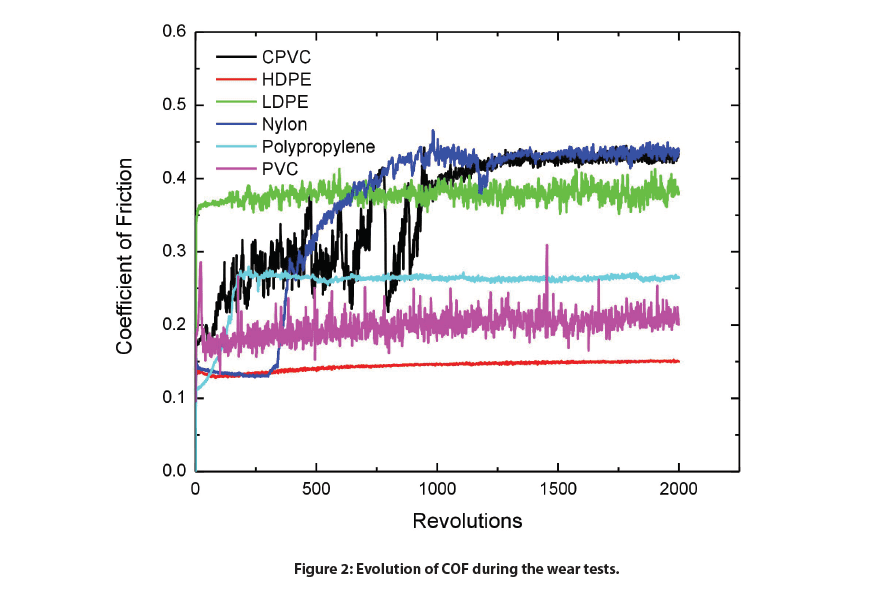

La tasa de desgaste es un factor vital para determinar la vida útil de los materiales, mientras que la fricción desempeña un papel fundamental durante las aplicaciones tribológicas. La figura 2 compara la evolución del COF de diferentes polímeros frente a la bola de Al2O3 durante las pruebas de desgaste. El COF sirve como indicador de cuándo se producen fallos y el proceso de desgaste entra en una nueva etapa. Entre los polímeros probados, el HDPE mantiene el COF constante más bajo, de ~0,15, a lo largo de toda la prueba de desgaste. El COF suave implica que se forma un contacto tribológico estable.

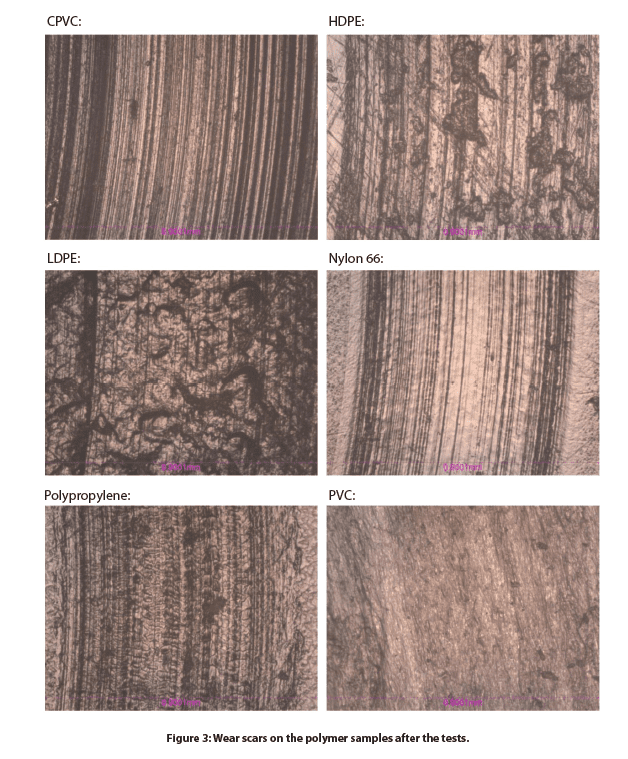

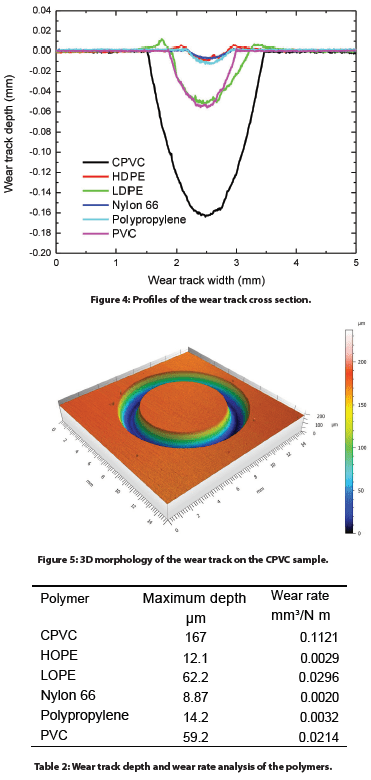

Las figuras 3 y 4 comparan las huellas de desgaste de las muestras de polímero después de medir la prueba con el microscopio óptico. El perfilómetro 3D sin contacto in situ determina con precisión el volumen de desgaste de las muestras de polímero, lo que permite calcular con exactitud las tasas de desgaste de 0,0029, 0,0020 y 0,0032 m3/N m, respectivamente. En comparación, la muestra de CPVC muestra la tasa de desgaste más alta, de 0,1121 m3/N m. En la huella de desgaste del CPVC se observan profundas marcas de desgaste paralelas.

CONCLUSIÓN

La resistencia al desgaste de los polímeros desempeña un papel fundamental en su rendimiento. En este estudio, demostramos que el tribómetro Nanovea evalúa el coeficiente de fricción y la tasa de desgaste de diferentes polímeros en un

de manera bien controlada y cuantitativa. El HDPE presenta el COF más bajo, ~0,15, entre los polímeros probados. Las muestras de HDPE, nailon 66 y polipropileno poseen bajos índices de desgaste de 0,0029, 0,0020 y 0,0032 m3/N m, respectivamente. La combinación de baja fricción y gran resistencia al desgaste hace que el HDPE sea un buen candidato para aplicaciones tribológicas de polímeros.

El perfilómetro 3D sin contacto in situ permite medir con precisión el volumen de desgaste y ofrece una herramienta para analizar la morfología detallada de las huellas de desgaste, lo que proporciona una mayor comprensión de los mecanismos fundamentales del desgaste.

AHORA, HABLEMOS DE SU SOLICITUD

Acabado superficial de paneles alveolares con perfilometría 3D

INTRODUCCIÓN

La rugosidad, la porosidad y la textura de la superficie del panel alveolar son factores críticos que deben cuantificarse para el diseño final del panel. Estas cualidades superficiales pueden correlacionarse directamente con las características estéticas y funcionales de la superficie del panel. Una mejor comprensión de la textura y la porosidad de la superficie puede ayudar a optimizar el procesamiento y la fabricabilidad de la superficie del panel. Se necesita una medición cuantitativa, precisa y confiable de la superficie del panel alveolar para controlar los parámetros superficiales para los requisitos de aplicación y pintura. Los sensores sin contacto Nanovea 3D utilizan una tecnología confocal cromática única capaz de medir con precisión estas superficies de los paneles.

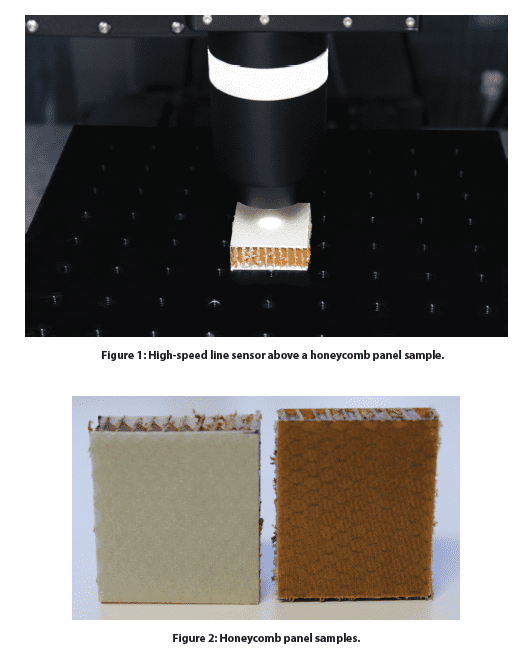

OBJETIVO DE MEDICIÓN

En este estudio, se utilizó la plataforma Nanovea HS2000 equipada con un sensor lineal de alta velocidad para medir y comparar dos paneles alveolares con diferentes acabados superficiales. Presentamos el Nanovea perfilómetro sin contacto’Capacidad para proporcionar mediciones de perfilado 3D rápidas y precisas, así como análisis exhaustivos y detallados del acabado superficial.

RESULTADOS Y DISCUSIÓN

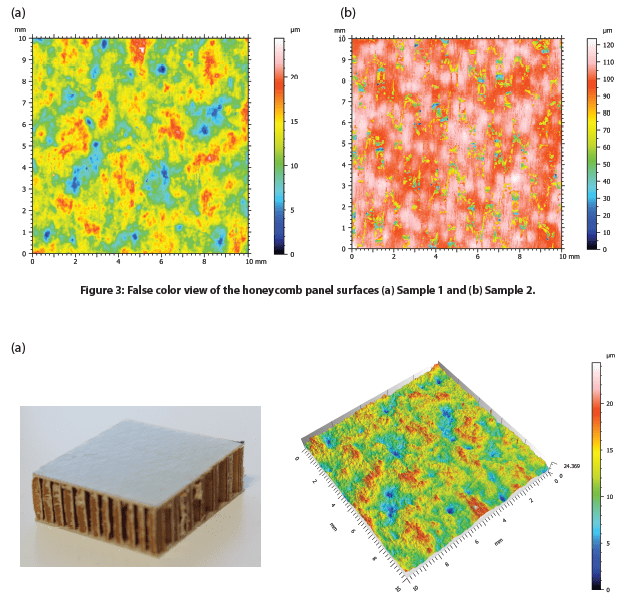

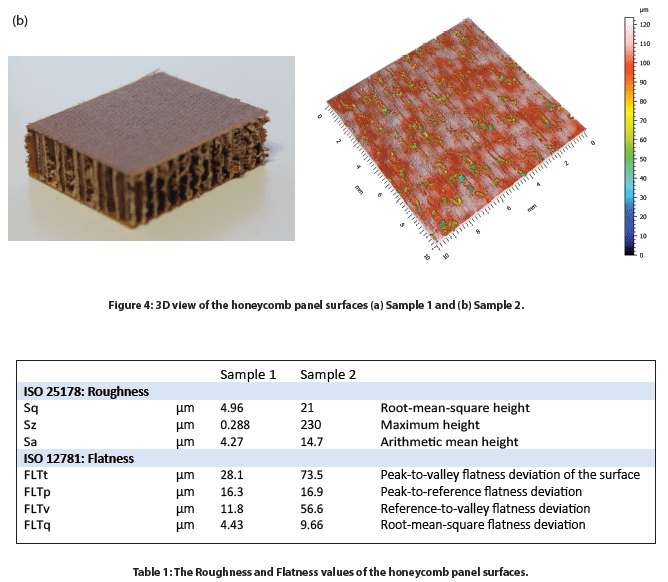

Se midió la superficie de dos muestras de paneles alveolares con diferentes acabados superficiales, denominadas Muestra 1 y Muestra 2. La falsa color y la vista en 3D de las superficies de las Muestras 1 y 2 se muestran en la Figura 3 y la Figura 4, respectivamente. Los valores de rugosidad y planitud se calcularon mediante un software de análisis avanzado y se comparan en la Tabla 1. La muestra 2 presenta una superficie más porosa en comparación con la muestra 1. Como resultado, la muestra 2 posee una rugosidad Sa más alta, de 14,7 µm, en comparación con el valor Sa de 4,27 µm de la muestra 1.

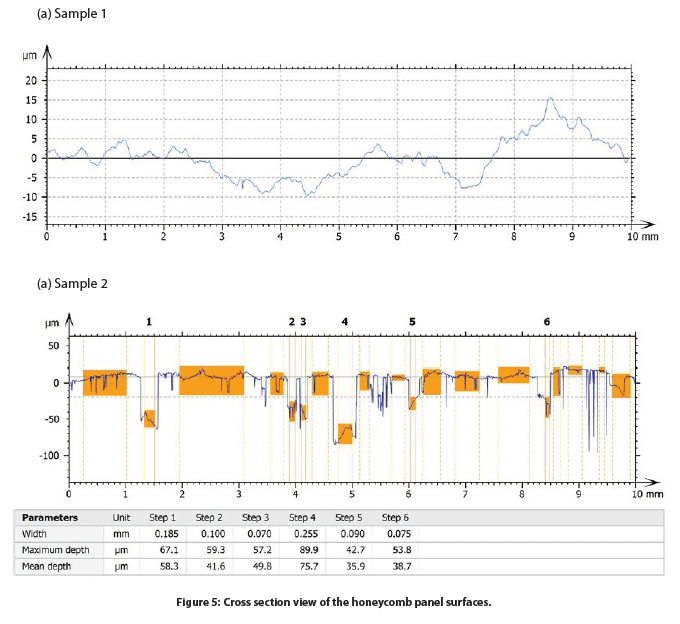

En la figura 5 se comparan los perfiles 2D de las superficies de los paneles alveolares, lo que permite a los usuarios realizar una comparación visual del cambio de altura en diferentes puntos de la superficie de la muestra. Podemos observar que la muestra 1 presenta una variación de altura de ~25 µm entre el pico más alto y el valle más bajo. Por otro lado, la muestra 2 muestra varios poros profundos en todo el perfil 2D. El software de análisis avanzado tiene la capacidad de localizar y medir automáticamente la profundidad de seis poros relativamente profundos, como se muestra en la tabla de la figura 4.b Muestra 2. El poro más profundo de los seis tiene una profundidad máxima de casi 90 µm (paso 4).

Para investigar más a fondo el tamaño y la distribución de los poros de la muestra 2, se realizó una evaluación de la porosidad, cuyos resultados se analizan en la siguiente sección. La vista en corte se muestra en la figura 5 y los resultados se resumen en la tabla 2. Se puede observar que los poros, marcados en color azul en la figura 5, tienen una distribución relativamente homogénea en la superficie de la muestra. El área proyectada de los poros constituye el 18,91 % de la superficie total de la muestra. El volumen por mm² del total de poros es de ~0,06 mm³. Los poros tienen una profundidad media de 42,2 µm y la profundidad máxima es de 108,1 µm.

CONCLUSIÓN

En esta aplicación, hemos demostrado que la plataforma Nanovea HS2000 equipada con un sensor lineal de alta velocidad es una herramienta ideal para analizar y comparar el acabado superficial de muestras de paneles alveolares de forma rápida y precisa. Los escaneos de perfilometría de alta resolución, junto con un software de análisis avanzado, permiten una evaluación completa y cuantitativa del acabado superficial de las muestras de paneles alveolares.

Los datos que se muestran aquí representan solo una pequeña parte de los cálculos disponibles en el software de análisis. Los perfilómetros Nanovea miden prácticamente cualquier superficie para una amplia gama de aplicaciones en los sectores de semiconductores, microelectrónica, energía solar, fibra óptica, automoción, aeroespacial, metalurgia, mecanizado, recubrimientos, farmacéutico, biomédico, medioambiental y muchos otros.

AHORA, HABLEMOS DE SU SOLICITUD

Medición de la relajación de tensiones mediante nanoindentación

INTRODUCCIÓN

Los materiales viscoelásticos se caracterizan por tener propiedades tanto viscosas como elásticas. Estos materiales están sujetos a una disminución de la tensión dependiente del tiempo (relajación de la tensión) bajo una deformación constante, lo que conduce a una pérdida significativa de la fuerza de contacto inicial. La relajación de la tensión depende del tipo de material, la textura, la temperatura, la tensión inicial y el tiempo. Comprender la relajación de la tensión es fundamental para seleccionar los materiales óptimos que tengan la resistencia y la flexibilidad (relajación) necesarias para aplicaciones específicas.

Importancia de la medición de la relajación de tensiones

Según la norma ASTM E328i, “Métodos de prueba estándar para la relajación de tensiones en materiales y estructuras”, inicialmente se aplica una fuerza externa sobre un material o estructura con un penetrador hasta que alcanza una fuerza máxima predeterminada. Una vez alcanzada la fuerza máxima, la posición del penetrador se mantiene constante a esta profundidad. A continuación, se mide el cambio en la fuerza externa necesaria para mantener la posición del penetrador en función del tiempo. La dificultad de los ensayos de relajación de tensiones radica en mantener constante la profundidad. El ensayador mecánico Nanovea nanoindentación El módulo mide con precisión la relajación de la tensión aplicando un control de bucle cerrado (retroalimentación) de la profundidad con un actuador piezoeléctrico. El actuador reacciona en tiempo real para mantener la profundidad constante, mientras que el cambio en la carga se mide y registra mediante un sensor de carga de alta sensibilidad. Esta prueba se puede realizar en prácticamente todo tipo de materiales sin necesidad de requisitos estrictos en cuanto a las dimensiones de la muestra. Además, se pueden realizar múltiples pruebas en una sola muestra plana para garantizar la repetibilidad de la prueba.

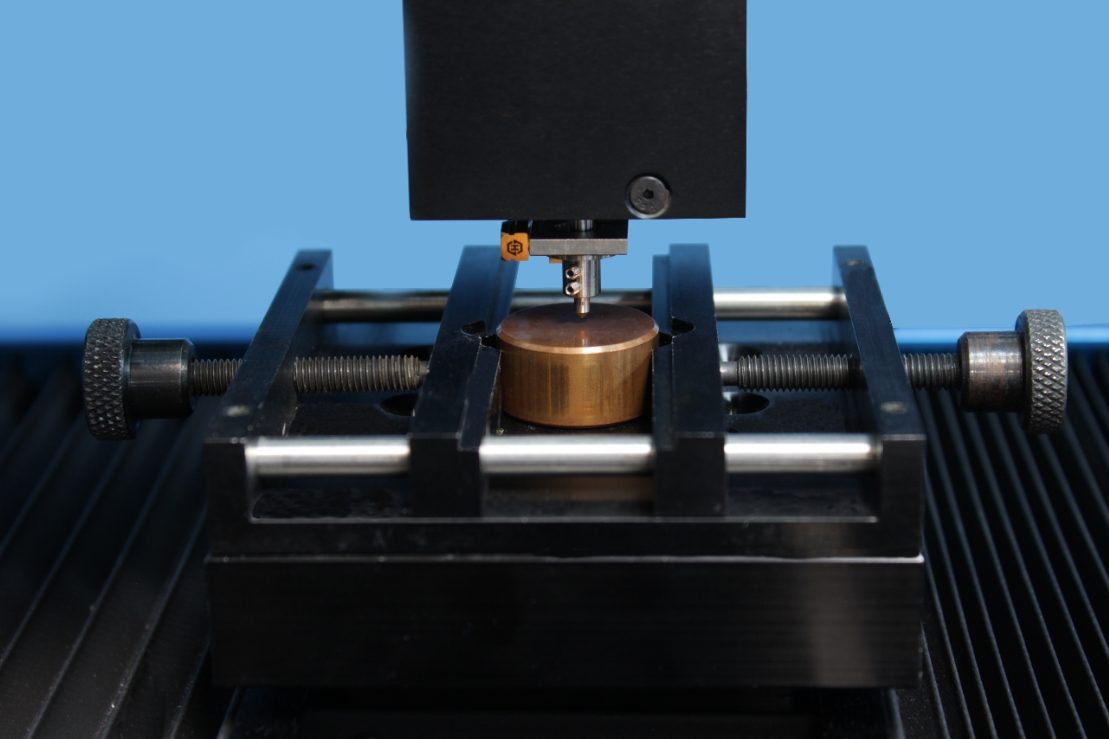

OBJETIVO DE MEDICIÓN

En esta aplicación, el módulo de nanoindentación del Nanovea Mechanical Tester mide el comportamiento de relajación de la tensión de una muestra de acrílico y cobre. Demostramos que el Nanovea Comprobador mecánico Es una herramienta ideal para evaluar el comportamiento viscoelástico dependiente del tiempo de los materiales poliméricos y metálicos.

CONDICIONES DE ENSAYO

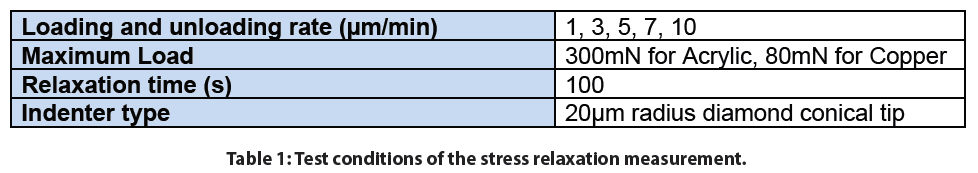

La relajación de la tensión de una muestra de acrílico y otra de cobre se midió con el módulo de nanoindentación del Nanovea Mechanical Tester. Se aplicaron diferentes velocidades de carga de indentación, que oscilaron entre 1 y 10 µm/min. La relajación se midió a una profundidad fija una vez que se alcanzó la carga máxima objetivo. Se implementó un periodo de mantenimiento de 100 segundos a una profundidad fija y se registró el cambio en la carga a medida que transcurría el tiempo de mantenimiento. Todas las pruebas se realizaron en condiciones ambientales (temperatura ambiente de 23 °C) y los parámetros de la prueba de indentación se resumen en la Tabla 1.

RESULTADOS Y DISCUSIÓN

Figura 2 muestra la evolución del desplazamiento y la carga en función del tiempo durante la medición de la relajación de la tensión de una muestra acrílica y una velocidad de carga de indentación de 3 µm/min como ejemplo. La totalidad de esta prueba se puede dividir en tres etapas: carga, relajación y descarga. Durante la etapa de carga, la profundidad aumentó linealmente a medida que la carga aumentaba progresivamente. La etapa de relajación se inició una vez que se alcanzó la carga máxima. Durante esta etapa, se mantuvo una profundidad constante durante 100 segundos utilizando la función de control de profundidad de bucle cerrado del instrumento y se observó que la carga disminuyó con el tiempo. La prueba completa concluyó con una etapa de descarga para retirar el indentador de la muestra acrílica.

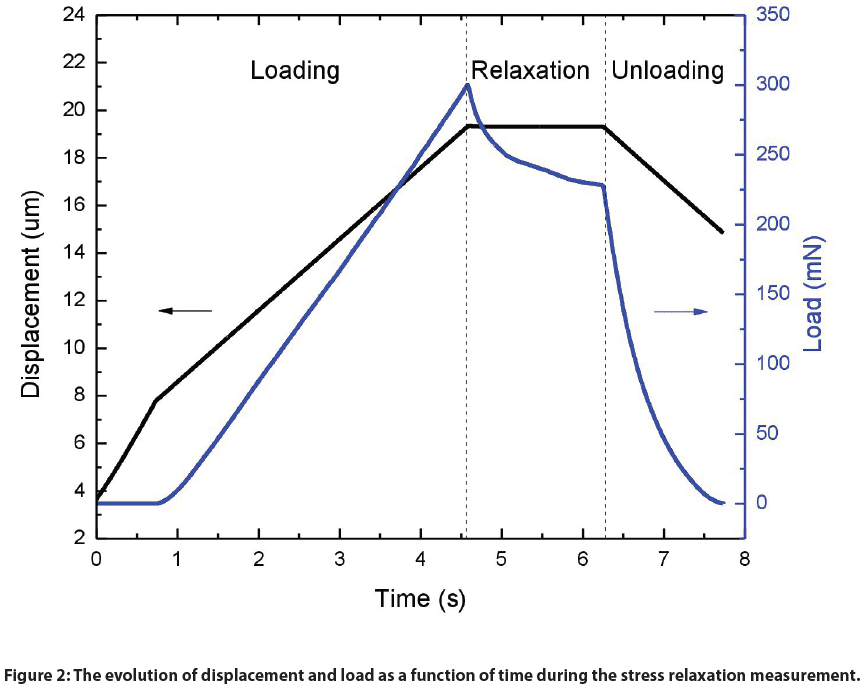

Se realizaron pruebas de indentación adicionales utilizando las mismas velocidades de carga del indentador, pero excluyendo el periodo de relajación (fluencia). A partir de estas pruebas se obtuvieron gráficos de carga frente a desplazamiento, que se combinaron en los gráficos de la figura 3 para las muestras de acrílico y cobre. A medida que la velocidad de carga del penetrador disminuyó de 10 a 1 µm/min, la curva de carga-desplazamiento se desplazó progresivamente hacia profundidades de penetración más altas tanto para el acrílico como para el cobre. Este aumento de la deformación en función del tiempo se debe al efecto de fluencia viscoelástica de los materiales. Una velocidad de carga más baja permite que un material viscoelástico tenga más tiempo para reaccionar a la tensión externa a la que se ve sometido y deformarse en consecuencia.

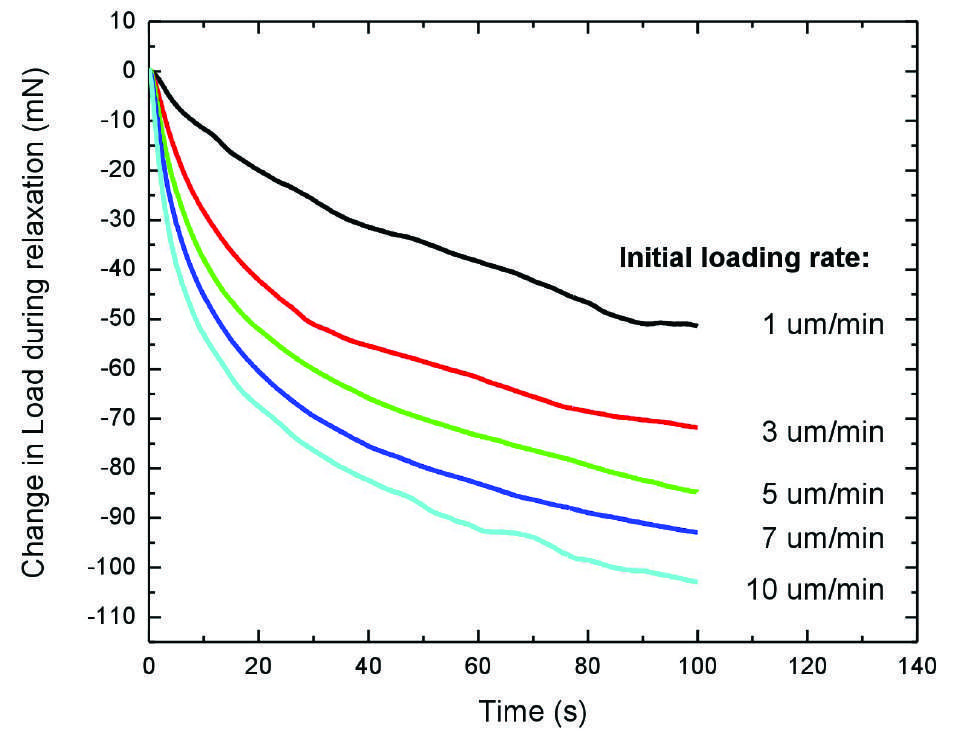

La evolución de la carga a una deformación constante utilizando diferentes velocidades de carga de indentación se representa en la figura 4 para ambos materiales probados. La carga disminuyó a un ritmo mayor en las primeras etapas de la fase de relajación (período de mantenimiento de 100 segundos) de las pruebas y se ralentizó una vez que el tiempo de mantenimiento alcanzó los ~50 segundos. Los materiales viscoelásticos, como los polímeros y los metales, presentan una mayor tasa de pérdida de carga cuando se someten a velocidades de carga de indentación más altas. La tasa de pérdida de carga durante la relajación aumentó de 51,5 a 103,2 mN para el acrílico, y de 15,0 a 27,4 mN para el cobre, respectivamente, a medida que la velocidad de carga de indentación aumentaba de 1 a 10 µm/min, como se resume en Figura 5.

Como se menciona en la norma ASTM E328ii, el principal problema que se presenta en los ensayos de relajación de tensiones es la incapacidad del instrumento para mantener una deformación/profundidad constante. El ensayador mecánico Nanovea proporciona mediciones de relajación de tensión excelentes y precisas gracias a su capacidad para aplicar un control de bucle cerrado de retroalimentación de la profundidad entre el actuador piezoeléctrico de acción rápida y el sensor de profundidad del condensador independiente. Durante la fase de relajación, el actuador piezoeléctrico ajusta el indentador para mantener su restricción de profundidad constante en tiempo real, mientras que el cambio en la carga se mide y registra mediante un sensor de carga independiente de alta precisión.

CONCLUSIÓN

Se midió la relajación de la tensión de una muestra de acrílico y otra de cobre utilizando el módulo de nanoindentación del probador mecánico Nanovea a diferentes velocidades de carga. Se alcanza una mayor profundidad máxima cuando las indentaciones se realizan a velocidades de carga más bajas debido al efecto de fluencia del material durante la carga. Tanto la muestra de acrílico como la de cobre muestran un comportamiento de relajación de la tensión cuando se mantiene constante la posición del indentador a una carga máxima objetivo. Se observaron cambios mayores en la pérdida de carga durante la etapa de relajación en las pruebas con velocidades de carga de indentación más altas.

La prueba de relajación de tensiones realizada por el Nanovea Mechanical Tester demuestra la capacidad del instrumento para cuantificar y medir de forma fiable el comportamiento viscoelástico dependiente del tiempo de los materiales poliméricos y metálicos. Cuenta con unos módulos Nano y Micro multifunción sin igual en una única plataforma. Los módulos de control de humedad y temperatura se pueden combinar con estos instrumentos para realizar pruebas ambientales aplicables a una amplia gama de industrias. Tanto el módulo Nano como el Micro incluyen modos de prueba de rayado, dureza y desgaste, lo que proporciona la gama más amplia y fácil de usar de capacidades de prueba mecánica disponible en un solo sistema.

AHORA, HABLEMOS DE SU SOLICITUD

Comprensión de los fallos en los recubrimientos mediante pruebas de rayado

Introducción:

La ingeniería de superficies de los materiales desempeña un papel importante en diversas aplicaciones funcionales, que van desde la apariencia decorativa hasta la protección de los sustratos contra el desgaste, la corrosión y otras formas de agresión. Un factor importante y determinante que influye en la calidad y la vida útil de los recubrimientos es su fuerza cohesiva y adhesiva.

Categorías

- Notas de aplicación

- Bloque sobre tribología anular

- Tribología de la corrosión

- Pruebas de fricción | Coeficiente de fricción

- Pruebas mecánicas a alta temperatura

- Tribología de alta temperatura

- Humedad y gases Tribología

- Humedad Pruebas mecánicas

- Indentación | Fluencia y relajación

- Indentación | Resistencia a la fractura

- Indentación | Dureza y elasticidad

- Indentación | Pérdida y almacenamiento

- Indentación | Esfuerzo frente a deformación

- Indentación | Límite elástico y fatiga

- Pruebas de laboratorio

- Tribología lineal

- Pruebas mecánicas de líquidos

- Tribología de líquidos

- Tribología a baja temperatura

- Pruebas mecánicas

- Comunicado de prensa

- Perfilometría | Planitud y alabeo

- Perfilometría | Geometría y forma

- Perfilometría | Rugosidad y acabado

- Profilometría | Altura y grosor del escalón

- Profilometría | Textura y grano

- Perfilometría | Volumen y área

- Pruebas de perfilometría

- Tribología anillo sobre anillo

- Tribología rotacional

- Prueba de arañazos | Fallo adhesivo

- Prueba del rasguño | Fallo de cohesión

- Pruebas de arañazos | Desgaste en varias pasadas

- Pruebas de rayado | Dureza al rayado

- Pruebas de rayado Tribología

- Pruebas de tribología

- Sin categoría

Archivos

- noviembre 2025

- septiembre 2023

- agosto 2023

- junio 2023

- mayo 2023

- julio 2022

- mayo 2022

- abril 2022

- enero 2022

- diciembre 2021

- noviembre 2021

- octubre 2021

- septiembre 2021

- agosto 2021

- julio 2021

- junio 2021

- mayo 2021

- marzo 2021

- febrero 2021

- diciembre 2020

- noviembre 2020

- octubre 2020

- septiembre 2020

- julio 2020

- mayo 2020

- abril 2020

- marzo 2020

- febrero 2020

- enero 2020

- noviembre 2019

- octubre 2019

- septiembre 2019

- agosto 2019

- julio 2019

- junio 2019

- mayo 2019

- abril 2019

- marzo 2019

- enero 2019

- diciembre 2018

- noviembre 2018

- octubre 2018

- septiembre 2018

- julio 2018

- junio 2018

- abril 2018

- marzo 2018

- febrero 2018

- noviembre 2017

- octubre 2017

- septiembre 2017

- agosto 2017

- junio 2017

- mayo 2017

- marzo 2017

- febrero 2017

- enero 2017

- noviembre 2016

- octubre 2016

- agosto 2016

- julio 2016

- junio 2016

- mayo 2016

- abril 2016

- marzo 2016

- febrero 2016

- enero 2016

- diciembre 2015

- noviembre 2015

- octubre 2015

- septiembre 2015

- agosto 2015

- julio 2015

- junio 2015

- mayo 2015

- abril 2015

- marzo 2015

- febrero 2015

- enero 2015

- noviembre 2014

- octubre 2014

- septiembre 2014

- agosto 2014

- julio 2014

- junio 2014

- mayo 2014

- abril 2014

- marzo 2014

- febrero 2014

- enero 2014

- diciembre 2013

- noviembre 2013

- octubre 2013

- septiembre 2013

- agosto 2013

- julio 2013

- junio 2013

- mayo 2013

- abril 2013

- marzo 2013

- febrero 2013

- enero 2013

- diciembre 2012

- noviembre 2012

- octubre 2012

- septiembre 2012

- agosto 2012

- julio 2012

- junio 2012

- mayo 2012

- abril 2012

- marzo 2012

- febrero 2012

- enero 2012

- diciembre 2011

- noviembre 2011

- octubre 2011

- septiembre 2011

- agosto 2011

- julio 2011

- junio 2011

- mayo 2011

- noviembre 2010

- enero 2010

- abril 2009

- marzo 2009

- enero 2009

- diciembre 2008

- octubre 2008

- agosto 2007

- julio 2006

- marzo 2006

- enero 2005

- abril 2004