Archivos mensuales: septiembre 2019

Rugosidad superficial y características de una célula solar

Importancia de las pruebas de los paneles solares

Maximizar la absorción de energía de una célula solar es clave para la supervivencia de la tecnología como recurso renovable. Las múltiples capas de recubrimiento y protección de vidrio permiten la absorción, transmisión y reflexión de la luz necesaria para que las células fotovoltaicas funcionen. Dado que la mayoría de las células solares de consumo operan con una eficiencia de 15-18%, optimizar su producción de energía es una batalla constante.

Los estudios han demostrado que la rugosidad de la superficie desempeña un papel fundamental en la reflectancia de la luz. La capa inicial de vidrio debe ser lo más lisa posible para mitigar la reflectancia de la luz, pero las capas posteriores no siguen esta pauta. Es necesario un cierto grado de rugosidad en cada interfaz de recubrimiento para aumentar la posibilidad de dispersión de la luz dentro de sus respectivas zonas de agotamiento y aumentar la absorción de luz dentro de la célula. La optimización de la rugosidad de la superficie en estas regiones permite que la célula solar funcione al máximo de su capacidad y, con el sensor de alta velocidad Nanovea HS2000, la medición de la rugosidad de la superficie se puede realizar de forma rápida y precisa.

Objetivo de medición

En este estudio mostraremos las capacidades de Nanovea. Perfilómetro HS2000 con sensor de alta velocidad mediante la medición de la rugosidad superficial y las características geométricas de una célula fotovoltaica. Para esta demostración se medirá una célula solar monocristalina sin protección de vidrio, pero la metodología puede utilizarse para otras aplicaciones.

Procedimiento de ensayo y procedimientos

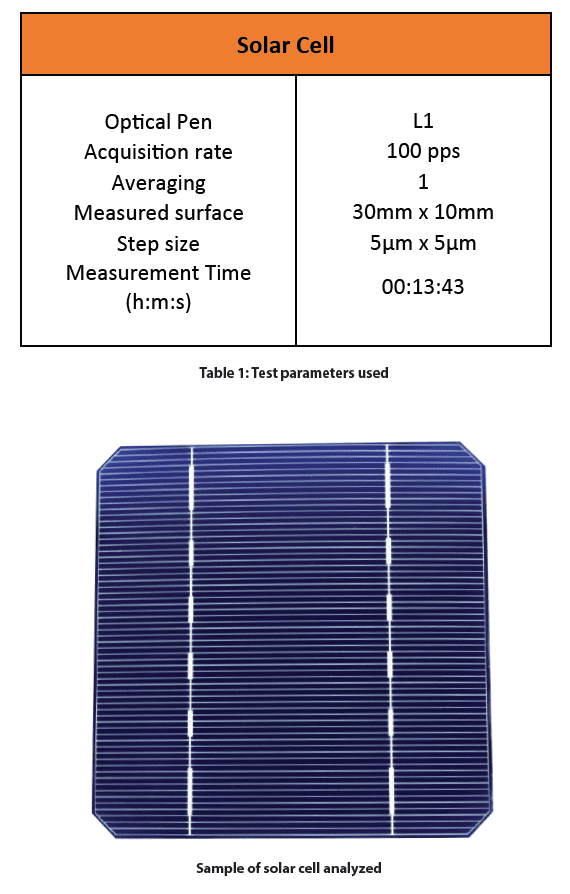

Se utilizaron los siguientes parámetros de prueba para medir la superficie de la célula solar.

Resultados y debate

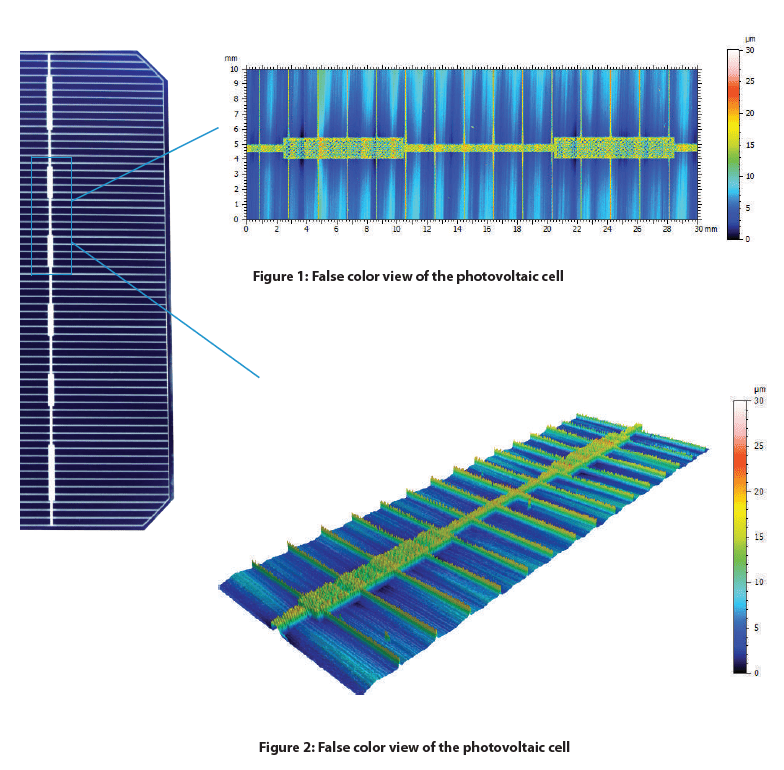

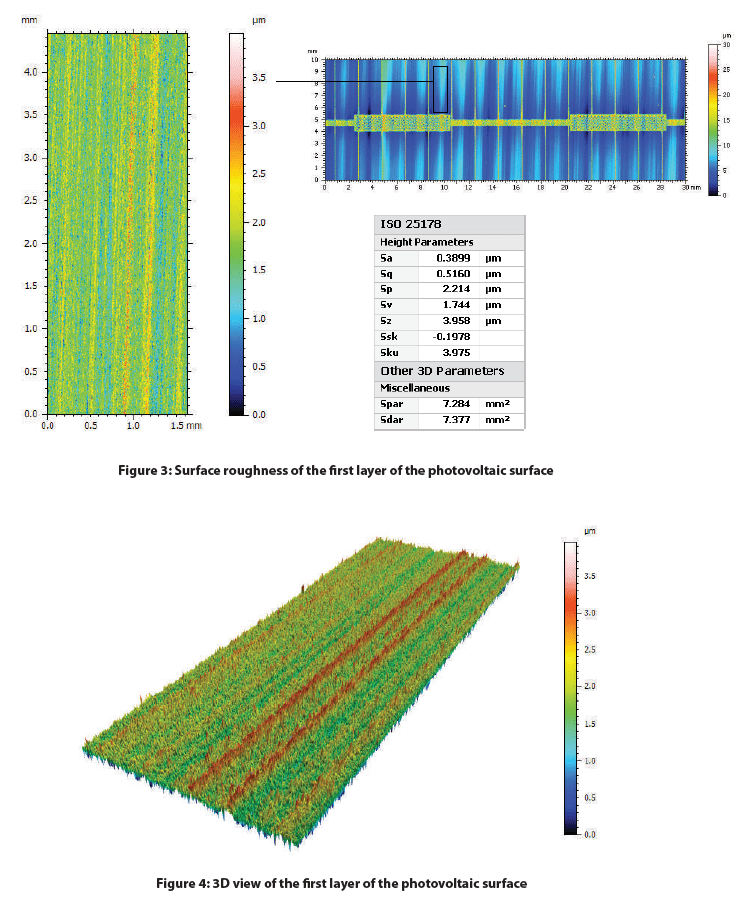

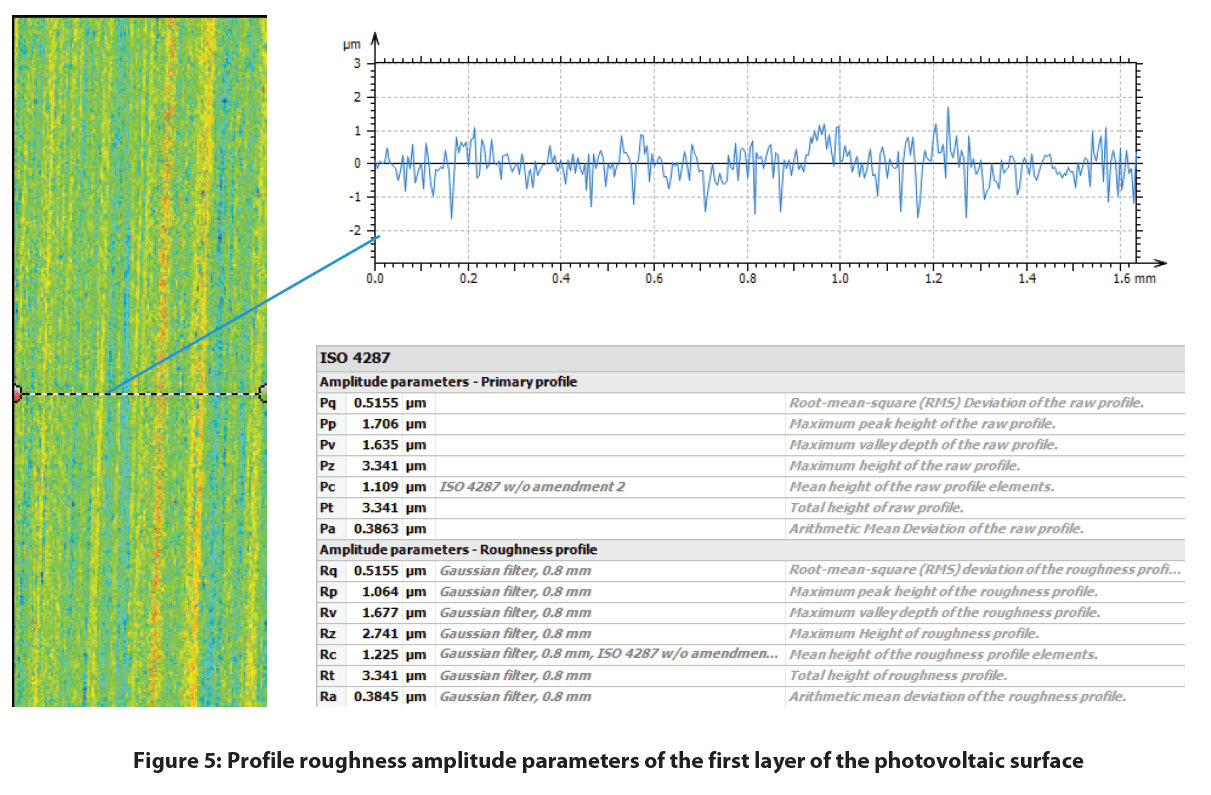

A continuación se muestra la vista en falso color 2D de la célula solar y una extracción del área de la superficie con sus respectivos parámetros de altura. Se aplicó un filtro gaussiano a ambas superficies y se utilizó un índice más agresivo para aplanar el área extraída. Esto excluye las formas (o ondulaciones) mayores que el índice de corte, dejando atrás las características que representan la rugosidad de la célula solar.

Conclusión

En este estudio, pudimos demostrar la capacidad del sensor lineal Nanovea HS2000 para medir la rugosidad y las características de la superficie de una célula fotovoltaica monocristalina. Con la capacidad de automatizar mediciones precisas de múltiples muestras y establecer límites de aprobación o rechazo, el sensor lineal Nanovea HS2000 es la opción perfecta para las inspecciones de control de calidad.

Referencia

1 Scholtz, Lubomir. Ladanyi, Libor. Mullerova, Jarmila. “Influencia de la rugosidad de la superficie en las características ópticas de las células solares multicapa“. Advances in Electrical and Electronic Engineering, vol. 12, n.º 6, 2014, pp. 631-638.

AHORA, HABLEMOS DE SU SOLICITUD

Comparación de gotas lubricantes para los ojos utilizando el tribómetro Nanovea T50

Importancia de probar las soluciones oftálmicas

Objetivo de medición

En este estudio, se midió el coeficiente de fricción (COF) de tres soluciones lubricantes diferentes para gotas oftálmicas utilizando la configuración de pin sobre disco en el tribómetro Nanovea T50.

Procedimiento de ensayo y procedimientos

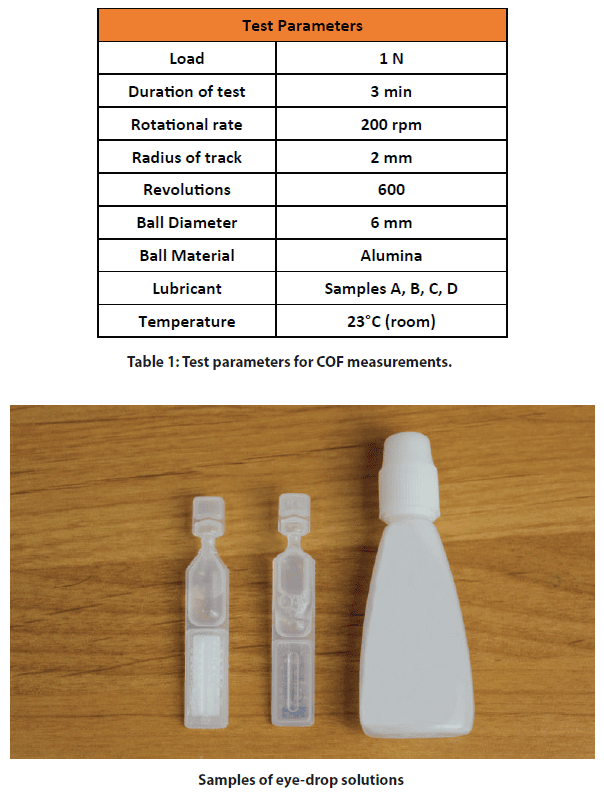

Se aplicó un pasador esférico de alúmina de 6 mm de diámetro a un portaobjetos de vidrio, utilizando cada solución oftálmica como lubricante entre las dos superficies. Los parámetros de prueba utilizados en todos los experimentos se resumen en la tabla 1 a continuación.

Resultados y debate

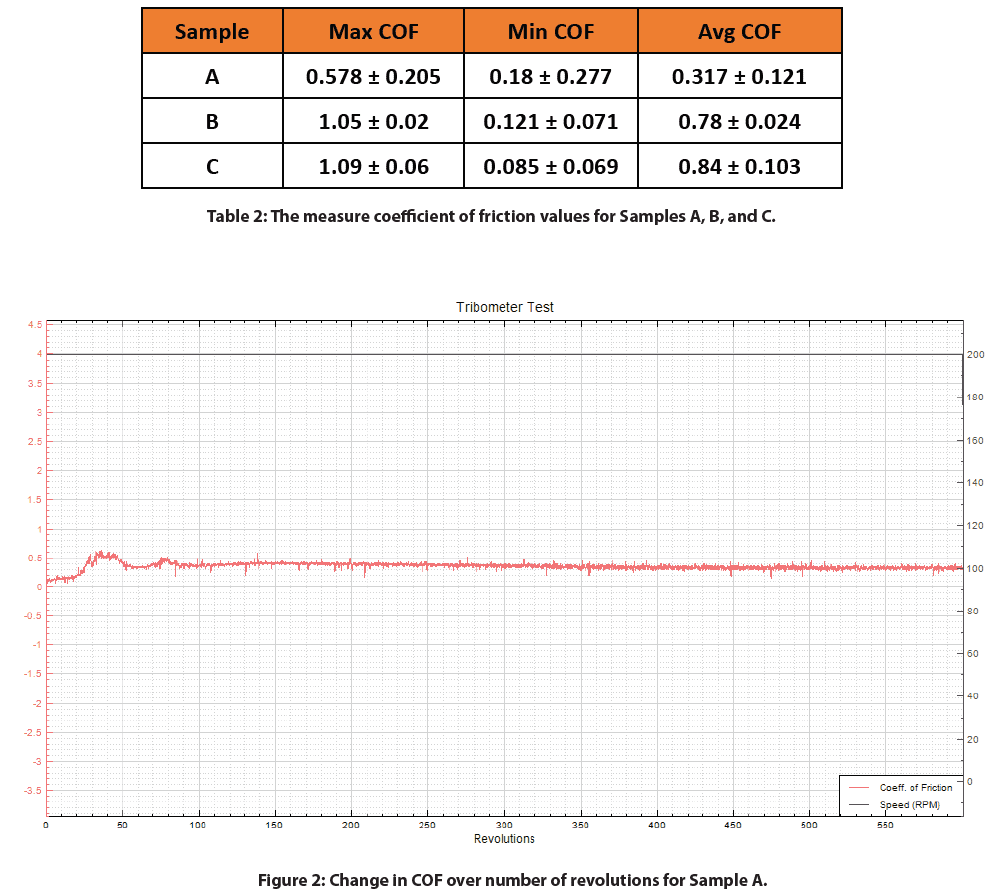

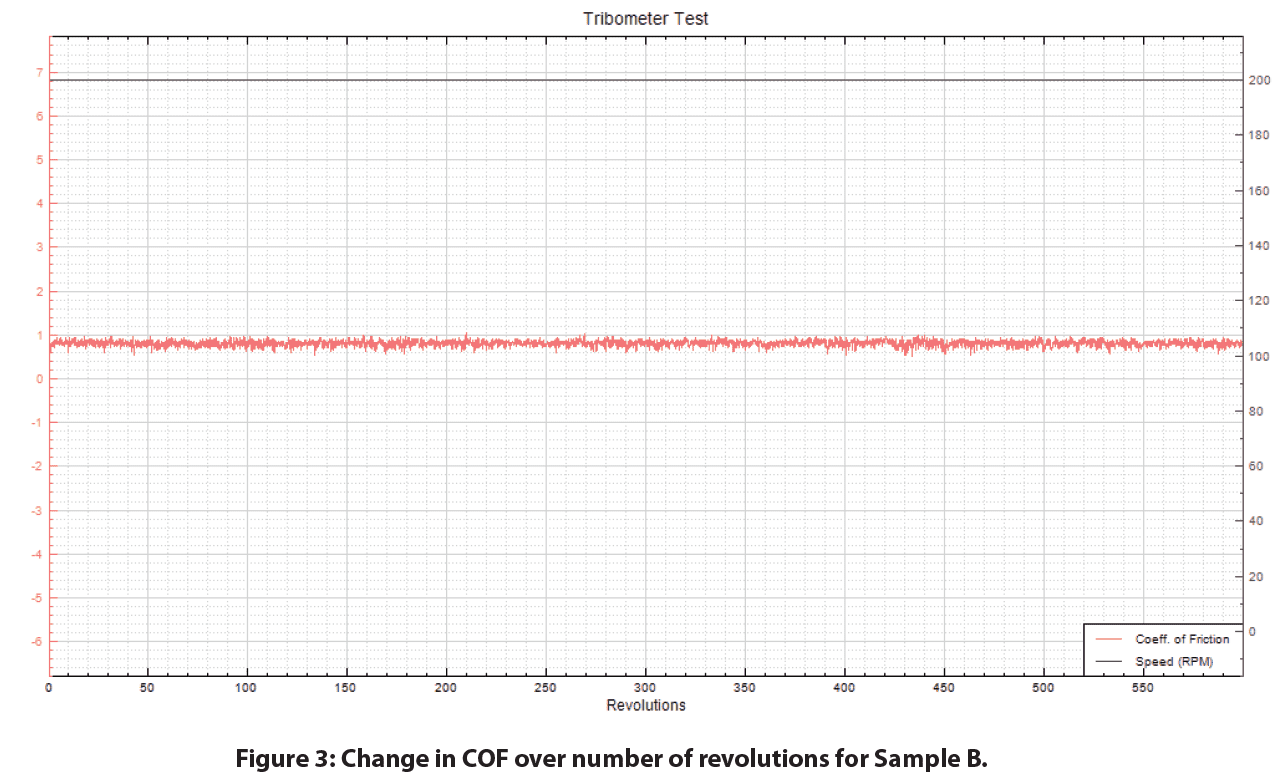

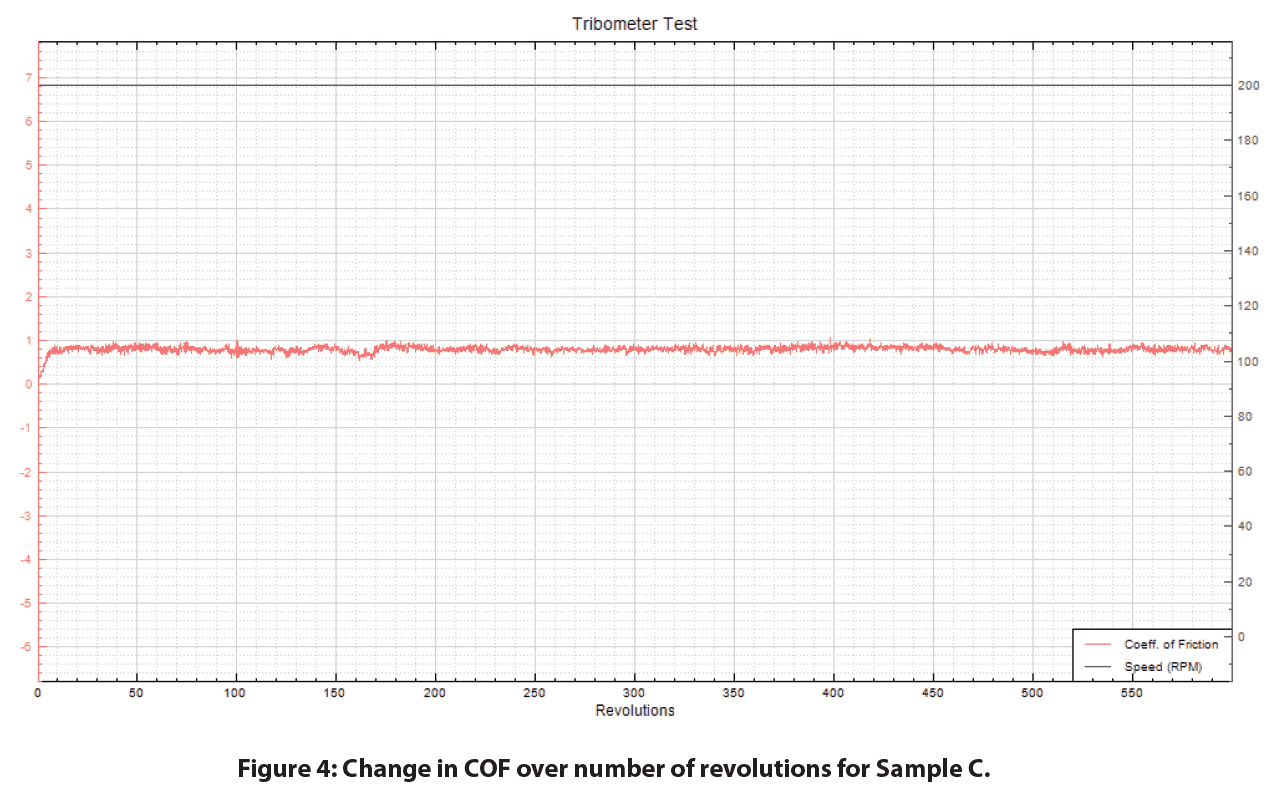

Los valores máximos, mínimos y medios del coeficiente de fricción para las tres soluciones oftálmicas diferentes probadas se recogen en la tabla 2 a continuación. Los gráficos del COF frente a las revoluciones para cada solución oftálmica se muestran en las figuras 2-4. El COF durante cada prueba se mantuvo relativamente constante durante la mayor parte de la duración total de la prueba. La muestra A tuvo el COF medio más bajo, lo que indica que tenía las mejores propiedades lubricantes.

Conclusión

En este estudio mostramos la capacidad del tribómetro Nanovea T50 para medir el coeficiente de fricción de tres soluciones oftálmicas. A partir de estos valores, demostramos que la muestra A tenía un coeficiente de fricción más bajo y, por lo tanto, presentaba una mejor lubricación en comparación con las otras dos muestras.

Nanovea Tribómetros ofrece pruebas de desgaste y fricción precisas y repetibles utilizando módulos rotativos y lineales que cumplen con las normas ISO y ASTM. También proporciona módulos opcionales de desgaste a alta temperatura, lubricación y tribocorrosión disponibles en un sistema preintegrado. Esta versatilidad permite a los usuarios simular mejor el entorno de aplicación real y mejorar la comprensión fundamental del mecanismo de desgaste y las características tribológicas de diversos materiales.

AHORA, HABLEMOS DE SU SOLICITUD

Categorías

- Notas de aplicación

- Bloque sobre tribología anular

- Tribología de la corrosión

- Pruebas de fricción | Coeficiente de fricción

- Pruebas mecánicas a alta temperatura

- Tribología de alta temperatura

- Humedad y gases Tribología

- Humedad Pruebas mecánicas

- Indentación | Fluencia y relajación

- Indentación | Resistencia a la fractura

- Indentación | Dureza y elasticidad

- Indentación | Pérdida y almacenamiento

- Indentación | Esfuerzo frente a deformación

- Indentación | Límite elástico y fatiga

- Pruebas de laboratorio

- Tribología lineal

- Pruebas mecánicas de líquidos

- Tribología de líquidos

- Tribología a baja temperatura

- Pruebas mecánicas

- Comunicado de prensa

- Perfilometría | Planitud y alabeo

- Perfilometría | Geometría y forma

- Perfilometría | Rugosidad y acabado

- Profilometría | Altura y grosor del escalón

- Profilometría | Textura y grano

- Perfilometría | Volumen y área

- Pruebas de perfilometría

- Tribología anillo sobre anillo

- Tribología rotacional

- Prueba de arañazos | Fallo adhesivo

- Prueba del rasguño | Fallo de cohesión

- Pruebas de arañazos | Desgaste en varias pasadas

- Pruebas de rayado | Dureza al rayado

- Pruebas de rayado Tribología

- Pruebas de tribología

- Sin categoría

Archivos

- noviembre 2025

- septiembre 2023

- agosto 2023

- junio 2023

- mayo 2023

- julio 2022

- mayo 2022

- abril 2022

- enero 2022

- diciembre 2021

- noviembre 2021

- octubre 2021

- septiembre 2021

- agosto 2021

- julio 2021

- junio 2021

- mayo 2021

- marzo 2021

- febrero 2021

- diciembre 2020

- noviembre 2020

- octubre 2020

- septiembre 2020

- julio 2020

- mayo 2020

- abril 2020

- marzo 2020

- febrero 2020

- enero 2020

- noviembre 2019

- octubre 2019

- septiembre 2019

- agosto 2019

- julio 2019

- junio 2019

- mayo 2019

- abril 2019

- marzo 2019

- enero 2019

- diciembre 2018

- noviembre 2018

- octubre 2018

- septiembre 2018

- julio 2018

- junio 2018

- abril 2018

- marzo 2018

- febrero 2018

- noviembre 2017

- octubre 2017

- septiembre 2017

- agosto 2017

- junio 2017

- mayo 2017

- marzo 2017

- febrero 2017

- enero 2017

- noviembre 2016

- octubre 2016

- agosto 2016

- julio 2016

- junio 2016

- mayo 2016

- abril 2016

- marzo 2016

- febrero 2016

- enero 2016

- diciembre 2015

- noviembre 2015

- octubre 2015

- septiembre 2015

- agosto 2015

- julio 2015

- junio 2015

- mayo 2015

- abril 2015

- marzo 2015

- febrero 2015

- enero 2015

- noviembre 2014

- octubre 2014

- septiembre 2014

- agosto 2014

- julio 2014

- junio 2014

- mayo 2014

- abril 2014

- marzo 2014

- febrero 2014

- enero 2014

- diciembre 2013

- noviembre 2013

- octubre 2013

- septiembre 2013

- agosto 2013

- julio 2013

- junio 2013

- mayo 2013

- abril 2013

- marzo 2013

- febrero 2013

- enero 2013

- diciembre 2012

- noviembre 2012

- octubre 2012

- septiembre 2012

- agosto 2012

- julio 2012

- junio 2012

- mayo 2012

- abril 2012

- marzo 2012

- febrero 2012

- enero 2012

- diciembre 2011

- noviembre 2011

- octubre 2011

- septiembre 2011

- agosto 2011

- julio 2011

- junio 2011

- mayo 2011

- noviembre 2010

- enero 2010

- abril 2009

- marzo 2009

- enero 2009

- diciembre 2008

- octubre 2008

- agosto 2007

- julio 2006

- marzo 2006

- enero 2005

- abril 2004