Archivos mensuales: noviembre 2015

Análisis termomecánico de la soldadura mediante nanoindentación

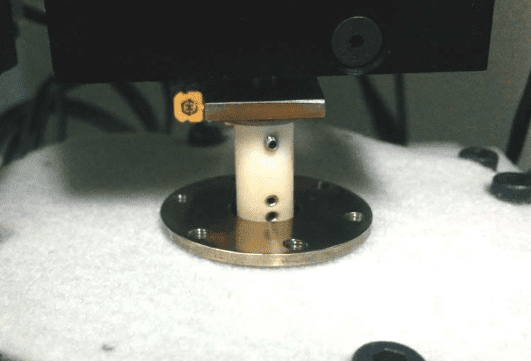

Las uniones soldadas están sometidas a estrés térmico y/o externo cuando la temperatura supera los 0,6 °C. Tm dónde Tm es el punto de fusión del material en grados Kelvin. El comportamiento de fluencia de las soldaduras a temperaturas elevadas puede influir directamente en la fiabilidad de las interconexiones soldadas.. Por consiguiente, se necesita un análisis termomecánico cuantitativo y confiable de la soldadura a diferentes temperaturas. El Módulo nano de Nanovea Comprobador mecánico aplica la carga mediante un piezoeléctrico de alta precisión y mide directamente la evolución de la fuerza y el desplazamiento. El avanzado horno de calentamiento proporciona una temperatura uniforme en la punta y la superficie de la muestra, lo que garantiza la precisión de la medición y minimiza la influencia de la deriva térmica.

Análisis termomecánico de la soldadura mediante nanoindentación

Dureza al rayado a alta temperatura mediante tribómetro

Los materiales se seleccionan en función de los requisitos de servicio. Para aplicaciones que implican cambios de temperatura y gradientes térmicos significativos, es fundamental investigar las propiedades mecánicas de los materiales a altas temperaturas para conocer a fondo los límites mecánicos. Los materiales, especialmente los polímeros, suelen ablandarse a altas temperaturas. Muchos fallos mecánicos se deben a la deformación por fluencia y a la fatiga térmica que sólo tienen lugar a temperaturas elevadas. Por lo tanto, se necesita una técnica fiable para medir la dureza al rayado a altas temperaturas con el fin de garantizar una selección adecuada de los materiales para aplicaciones a altas temperaturas.

Dureza al rayado a alta temperatura mediante tribómetro

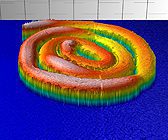

Morfología in situ a alta temperatura mediante perfilometría 3D

Los entornos con altas temperaturas pueden alterar la textura superficial, la rugosidad y la forma de los materiales, lo que puede provocar fallos en el funcionamiento de los dispositivos y averías mecánicas. Para garantizar la calidad de los materiales o dispositivos utilizados a temperaturas elevadas, es necesario contar con datos precisos y fiables. in situ El monitoreo de la morfología de la evolución de la forma a altas temperaturas es necesario para comprender el mecanismo de deformación de los materiales. Además, el monitoreo en tiempo real de la morfología de la superficie a altas temperaturas es muy útil en el procesamiento de materiales, como el mecanizado por láser. Los perfilómetros 3D sin contacto de Nanovea miden la morfología superficial de los materiales sin tocar la muestra, lo que evita introducir arañazos adicionales o alteraciones de la forma que pueden causar las tecnologías de contacto, como el palpador deslizante. Su capacidad de medición sin contacto también permite medir la forma de muestras fundidas.