Archivos mensuales: septiembre 2014

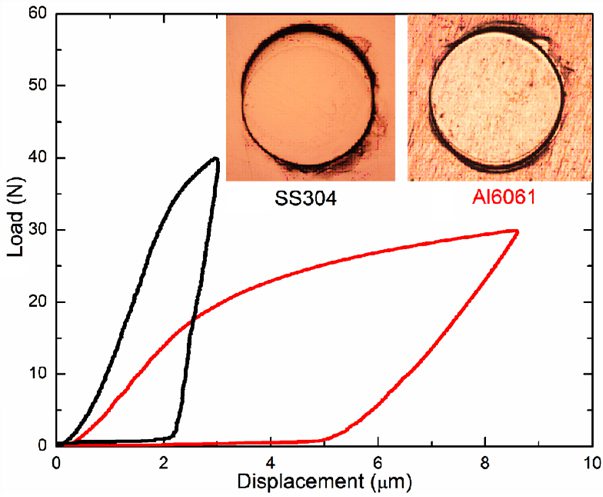

Medición innovadora probada en acero y aluminio

Por primera vez, Nanovea ha desarrollado un método revolucionario para obtener de forma fiable tanto el límite elástico (YS) como la resistencia a la tracción máxima (UTS) a través del técnica de sangría; lo que supone importantes ventajas en comparación con los ensayos de tracción tradicionales. Más información en la actualización de este mes. nota de aplicación.

Uso de la emisión acústica (AE) durante las pruebas de desgaste

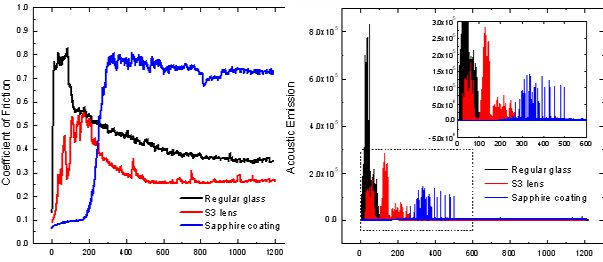

Durante Tribómetro En las pruebas de desgaste, el proceso de fricción constante de la contrapieza contra la muestra de prueba genera una serie de eventos, como deformación, agrietamiento, abrasión, transformación de fase y eliminación de material. Estos eventos de liberación rápida de tensión son las fuentes de AE. Una medición cuantificable y confiable de AE puede proporcionar más información sobre el mecanismo de falla por desgaste. Obtenga más información en este mes. nota de aplicación.

Vidrio para pruebas de desgaste con control de emisiones acústicas

Se compara el comportamiento frente al desgaste de tres tipos de vidrio (vidrio normal, vidrio Galaxy S3 y vidrio recubierto de zafiro) de forma controlada y supervisada utilizando Nanovea. Tribómetro equipado con un detector AE. En este estudio, nos gustaría mostrar la aplicación de la detección AE durante el desgaste y su correlación con la evolución del coeficiente de fricción (COF).

Vidrio para pruebas de desgaste con control de emisiones acústicas

Estos son algunos ejemplos de materiales que hemos probado este mes:

Mecánica:

• Nanoindentación de alambre de cobre micro

• Nanoindentación de recubrimientos metálicos sobre plástico.

• Compresión por nanoindentación de partículas.

• Mapeo por microindentación de implantes dentales.

• Dureza al rayado de las cubiertas electrónicas

Perfilometría 3D sin contacto:

• Topografía de artefactos arqueológicos

• Rugosidad del poliuretano

• Dimensiones: bordes afilados

• Coplanaridad de los componentes electrónicos

• Espesor de los recubrimientos

• Volumen y área de corrosión.

Tribología:

• Prueba de fricción de correas de poliuretano reforzado

• Prueba de fricción entre polímeros

• Pruebas de desgaste de polímeros duros

• Prueba de desgaste del acero tratado