Archivos mensuales: enero 2014

Estos son algunos ejemplos de materiales que hemos probado este mes:

Mecánica:

• Nanoindentación de secciones transversales de alambre.

• Nanoindentación de películas delgadas de Y2O3.

• Nanorrayaduras en películas poliméricas delgadas

• Nanorrayaduras en catéteres

• Microindentación del cemento de pozos petrolíferos.

Perfilometría 3D sin contacto:

• Rugosidad de los catéteres

• Acabado del cuero procesado

• Topografía de contaminantes de partículas de película delgada

• Coplanaridad de las matrices de rejilla de bolas

• Altura de los escalones de los microcanales

• Evaluación de la curva de Stribeck de diversos lubricantes.

Análisis de la deformación plástica inicial hasta el desgaste

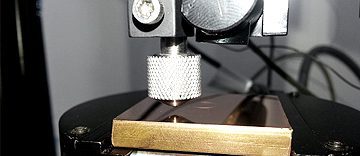

El proceso de desgaste de una muestra metálica (Cu 110) y una muestra polimérica (teflón) se simula de forma controlada y supervisada utilizando el Nanovea. Comprobador mecánico. En este estudio, nos gustaría demostrar que el control y la medición de la carga y la profundidad son ideales para el análisis del desgaste.

El efecto crítico de la deformación plástica inicial en el análisis del desgaste

Evaluación de la fricción a velocidad extremadamente baja en caucho

El coeficiente de fricción (COF) del caucho con respecto a diferentes materiales se mide de forma controlada y supervisada utilizando el tribómetro Nanovea. En este estudio, nos gustaría mostrar la capacidad del Tribómetro para medir el coeficiente de fricción de diferentes materiales a velocidades extremadamente bajas.

Evaluación de la fricción del caucho a velocidades extremadamente bajas mediante un tribómetro

Medición del acabado superficial del cuero procesado

En esta aplicación, el Nanovea ST400 Perfilómetro se utiliza para medir y comparar el acabado de la superficie de dos muestras de piel diferentes pero procesadas de forma muy similar. Se calcularán automáticamente varios parámetros de la superficie a partir del perfil de la misma. Aquí nos centraremos en la rugosidad de la superficie, la profundidad de los hoyuelos, la distancia entre ellos y su diámetro para realizar una evaluación comparativa.

Acabado superficial del cuero procesado mediante perfilometría 3D