博客档案

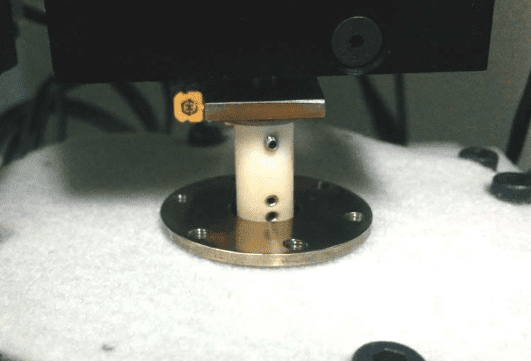

Thermomechanical Analysis of Solder Using Nanoindentation

Solder joints are subjected to thermal and/or external stress when the temperature exceeds 0.6 Tm where Tm is the melting point of the material in Kelvin. The creep behavior of solders at elevated temperatures can directly influence the reliability of solder interconnections. As a result, a reliable and quantitative thermomechanical analysis of the solder at different temperatures is in need. The Nano module of the Nanovea Mechanical Tester applies the load by a high-precision piezo and directly measures the evolution of force and displacement. The advanced heating oven provides a uniform temperature at the tip and sample surface, which ensures measuring accuracy and minimizes the influence of thermal drift.

Thermomechanical Analysis of Solder Using Nanoindentation