INTRODUCTION

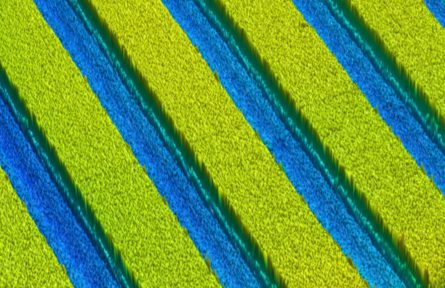

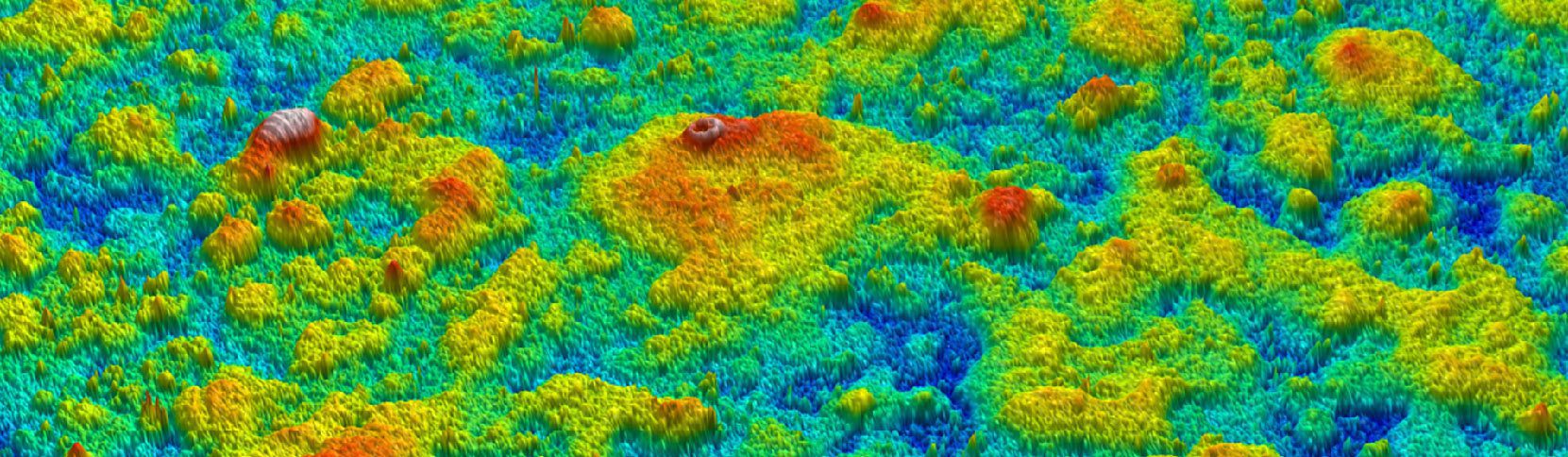

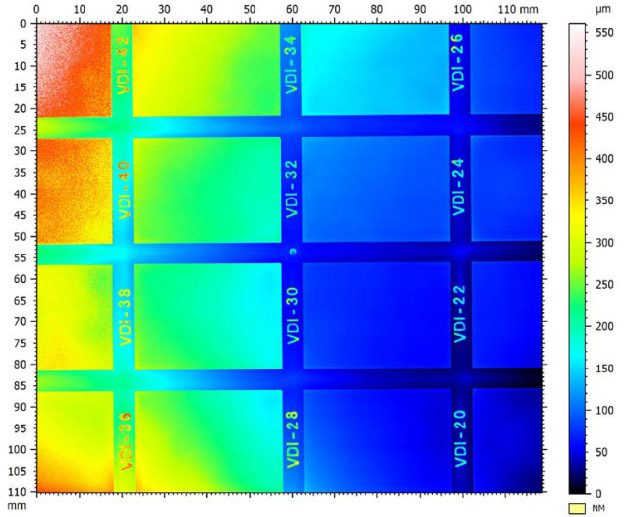

Surface roughness and texture are critical factors that impact the final quality and performance of a product. A thorough understanding of surface roughness, texture, and consistency is essential for selecting the best processing and control measures. Fast, quantifiable, and reliable inline inspection of product surfaces is in need to identify the defective products in time and optimize production line conditions.

IMPORTANCE OF 3D NON-CONTACT PROFILOMETER FOR IN-LINE SURFACE INSPECTION

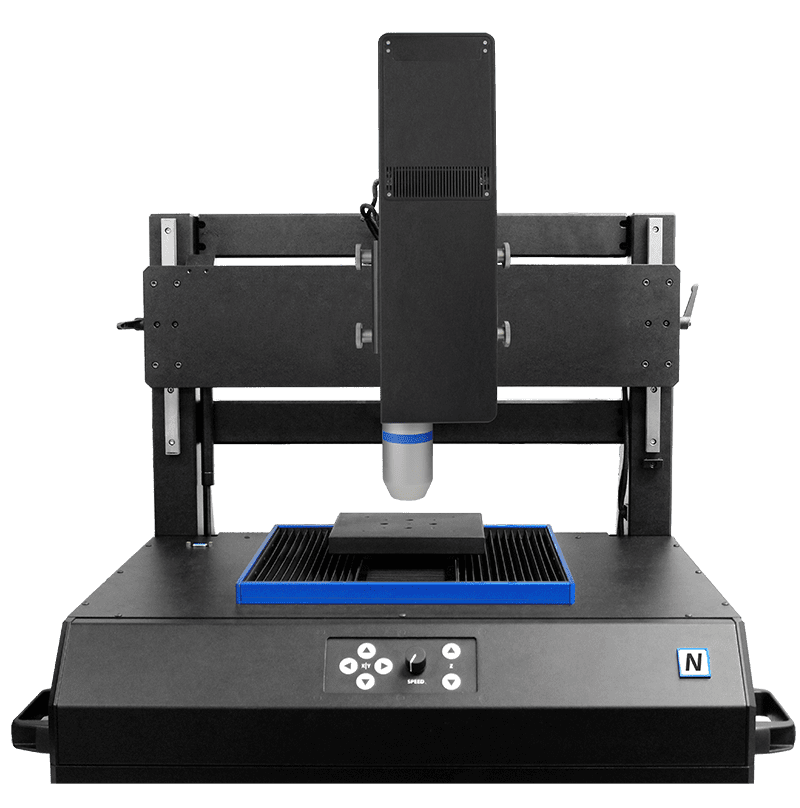

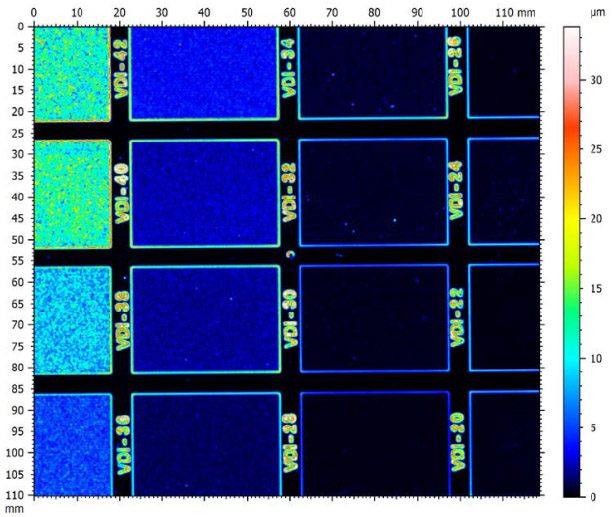

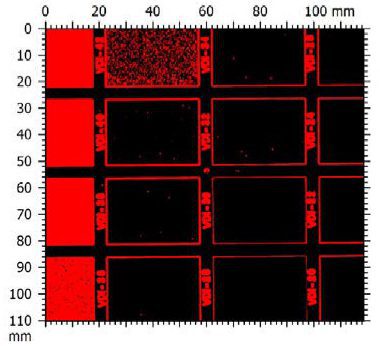

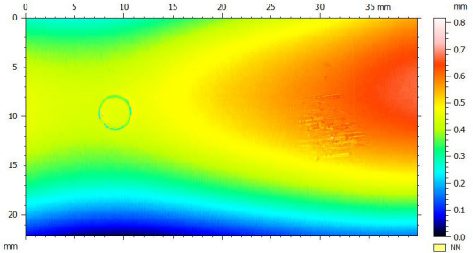

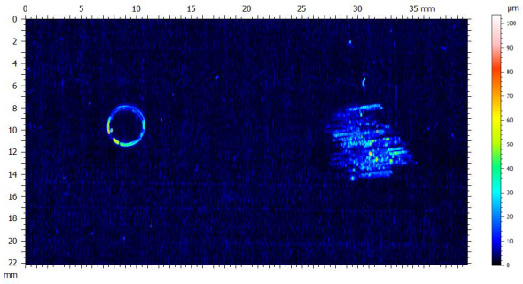

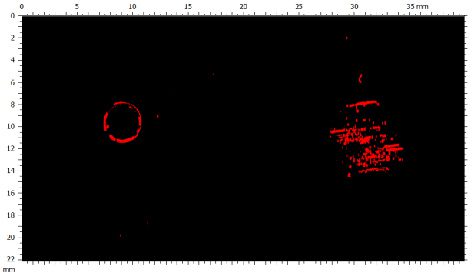

Surface defects in products result from materials processing and product manufacturing. Inline surface quality inspection ensures the tightest quality control of the end products. NANOVEA 3D Non-Contact Optical Profilers utilize Chromatic Light technology with unique capability to determine the roughness of a sample without contact. The line sensor enables scanning of the 3D profile of a large surface at a high speed. The roughness threshold, calculated in real-time by the analysis software, serves as a fast and reliable pass/fail tool.