SURFACE WEAR | FRICTION TRIBOLOGY TESTING

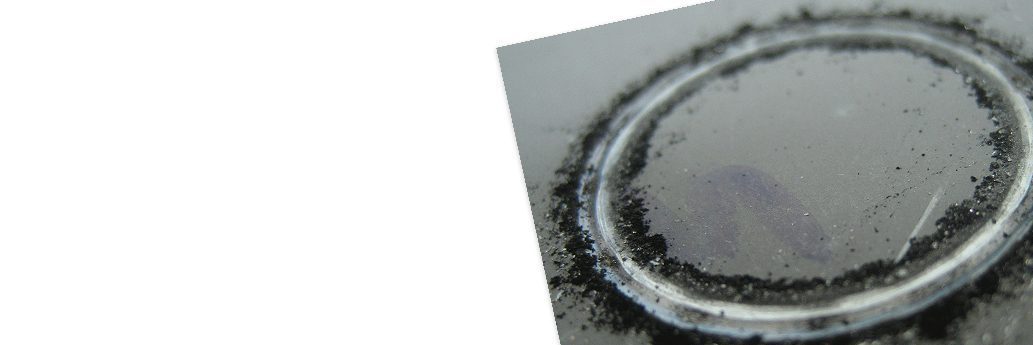

Based from ASTM G99 and ASTM G133. Using a ball, pin or flat holder is attached to the measuring arm which can be precisely positioned to a resolution of 2.5micron using the standard motorized table. With load added, the sample disk is rotated at a known speed which creates friction between the top ball, pin or flat and the bottom sample disk. For wear measurement, weight loss can be measured using a sensitive weight scale before and after the test. Furthermore, an LVDT can be attached to the measuring arm to record depth during the test. This gives the possibility to follow the change of wear rate versus time. Friction force is measured directly with a stiff load cell which offers high resolution with excellent mechanical and thermal stability; unlike other systems that rely only on LVDT for friction measurement. Several testing options are available to closely match real environment conditions including Temperature, Liquid and Atmosphere control. Additionally, to precisely measure wear track volume, a full 3D non-contact Optical profiler can be integrated on the Tribometer platform to quantify wear loss in a fast and convenient method without sample removal.

Properties Analyzed During Wear Friction Testing:

• Friction Coefficient

• Wear Rates

• Failure Points

• Electrical Contact

• Lubrication studies and others