Nanoindentation

Overview of Nanoindentation

Nanoindentation is a powerful tool for characterizing the mechanical properties of materials at small length scales. It enables researchers to measure and analyze material properties such as hardness, elastic modulus, fracture toughness, yield strength and fatigue with unprecedented accuracy and precision. Nanoindentation also provides an important means of simulating real-world conditions such as high or low temperature, liquid, humidity or vacuum environments. Different indenter types are available to accommodate different sample shapes and sizes while achieving consistent results across a wide range of materials including polymers, metals, composites and ceramics.

Table of Contents

Limitations of Traditional Indentation Tests

Traditional indentation tests are limited in their ability to measure material properties at small length scales. They also do not provide accurate and precise results for materials with varying shapes and sizes, as well as complex composites or ceramics. Nanoindentation is a more advanced testing method that offers researchers the ability to measure and analyze material properties such as hardness, elastic modulus, fracture toughness, yield strength and fatigue with greater accuracy and precision than traditional indentation tests. It is also capable of simulating real-world conditions such as high or low temperature, liquid, humidity or vacuum environments. Different indenter types can be used to accommodate different sample shapes and sizes while still providing consistent results across a wide range of materials including polymers, metals, composites and ceramics.

Advantages of Nanoindentation

Nanoindentation is a powerful tool for characterizing materials on the nanometer scale. It provides researchers with a variety of advantages over traditional indentation tests, including greater accuracy and precision when measuring material properties such as hardness, elastic modulus, fracture toughness, yield strength and fatigue. Nanoindentation also offers flexibility in terms of indenter type selection to accommodate different sample shapes and sizes while still providing consistent results across a wide range of materials including polymers, metals, composites and ceramics. Furthermore, it allows for the simulation of real-world conditions such as high or low temperature environments, liquid immersion testing or humidity/vacuum exposure. As such nanoindentation has become an invaluable tool for accurately assessing material behavior at the nanoscale level.

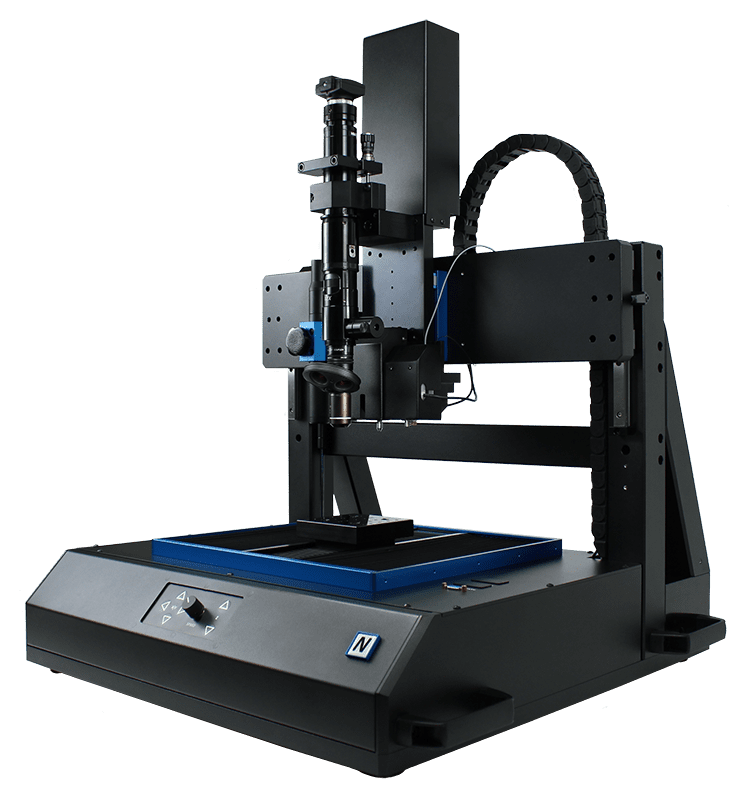

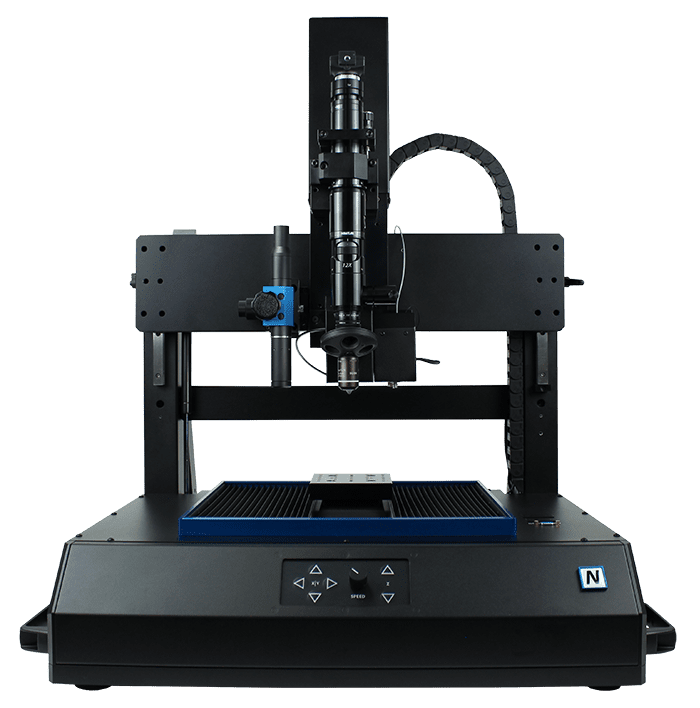

Advantages of NANOVEA Piezo Actuator with Independent Load and Depth Sensors vs Coil Actuator

NANOVEA Piezo Actuator with independent load and depth sensors are superior to traditional coil actuators in a number of ways. This system employs piezoelectric stacks that are capable of generating high forces at nanometer resolutions. The piezo actuators provide better control and reproducibility due to their ability to measure the load and displacement in real time, allowing for precise adjustments during tests. Additionally, piezo actuators feature far lower noise levels than coil actuators, allowing for more precise measurements to be taken.

DISCOVER NANOINDENTATION TESTING

WITH NANOVEA MECHANICAL TESTERS

NANOVEA Nanoindentation Software Features

- Recipes

- Export Raw Data and Images

- Real Time Display

- Automatic Reporting

- Multi-Language Support

- Compare Curves and Results on Same or Multi Samples

- DMA and Continuous Stiffness

- True Depth and Load Feedback Control Loading

NANOVEA Advanced Nanoindentation Automation

- FastMap: Mapping of Hardness & Elastic Modulus (3 sec per indent)

- Broadview Map Selection Tool: Advanced Mapping on stitched image

- Automated multi-sample testing (handles height variance of up to 50mm

- Navigation Plus: User Friendly surface navigation imaging

- Quick Approach, Auto Surface Detection and Auto Analysis

- Direct Easy Calibration Tools for Load & Depth

- Single Indent Area Function (European Patent No. 3076153)

- Quantifiable quality check for indenter (European Patent No. 3076153)

- Wizard (Patent Pending): Automatic Test Parameter generator

- Savable recipes of all macros programmed

Standards

Nanovea conducts scratch testing in compliance with established standards, ensuring accurate and reliable results for evaluating the mechanical properties of materials, while also offering tailored testing solutions designed for unique applications.

- ASTM E384 – Standard Test Method for Microindentation Hardness of Materials

- ASTM G171 – Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus

- ASTM E2546 – Standard Practice for Instrumented Indentation Testing

- ASTM B933 – Standard Test Method for Microindentation Hardness of Powder Metallurgy (PM) Materials

- ASTM D4065 – Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures

- ISO 14577 – Metallic materials — Instrumented indentation test for hardness and materials parameters

- DIN 50359 – Universal Hardness Testing Of Metallic Materials – Calibration Of Reference Blocks

Simulating Real-World Conditions

High and Low Temperature, Liquid, Humidity & Vacuum

Nanoindentation testing has become an essential technique for studying mechanical properties of various materials at small scales. However, the accuracy of such tests depends on simulating real-world conditions. This is where simulating high and low temperatures, liquid environments, and vacuum come into play. These factors have a significant impact on the mechanical properties of materials under study. For example, low-temperature testing can provide insight into material behavior at cryogenic temperatures, relevant for many industrial and space applications. Similarly, studying materials in humid and liquid environments can simulate the conditions materials would encounter in biological applications. Therefore, it is crucial to incorporate these real-world factors during nanoindentation testing to enhance its accuracy and to gain a better understanding of material performance and behavior.

Measurement and Analysis Techniques in Nanoindentation

Nanoindentation is a versatile technique that allows researchers to analyze various material properties at the nanoscale. Properties analyzed during nanoindentation include hardness, elastic modulus, and their relationship with temperature or humidity. Creep, stress relaxation under constant load and depth control, and stress-strain curves derived from Continuous Stiffness (CSM) and Multi-Load Cycles are also examined. Other properties such as recovery depth, restoration ratio, loss and storage modulus, fracture toughness, yield strength, and compression can be investigated.

Additionally, nanoindentation can be used to study fatigue, puncture resistance, adhesion stickiness, and Dynamic Mechanical Analysis (DMA) by performing frequency and temperature sweeps. Martens hardness versus depth, plastic and elastic deformations, and visual Vickers hardness are among the other properties that can be assessed through nanoindentation. This wide range of properties makes nanoindentation a powerful tool for characterizing materials and understanding their behavior under various conditions.

Hardness and Elastic Modulus

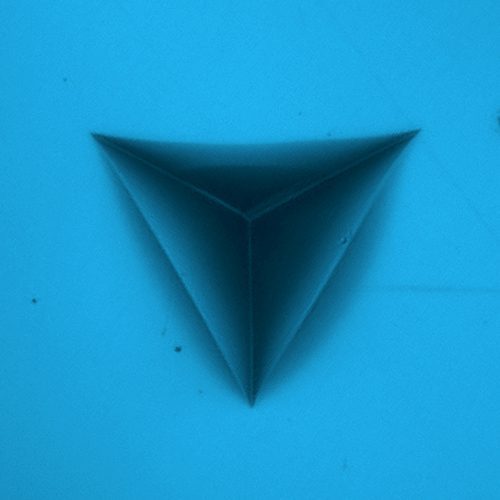

Nanoindentation testing is a technique used to measure a material’s mechanical properties at the nanoscale. Two key parameters obtained from nanoindentation testing are hardness and elastic modulus. Hardness, in this context, refers to a material’s resistance to plastic deformation caused by an indentation. Elastic modulus, on the other hand, describes a material’s ability to resist elastic deformation. Together, these two measures can yield important information about the mechanical behavior of a material, particularly at small length scales where traditional mechanical testing methods may not be applicable. These values have a significant impact on a material’s properties in various applications, including the performance of coatings, thin films, and other nanostructured materials.

Fracture toughness

Fracture toughness is a critical aspect of material science, especially in the field of nanoindentation testing. This parameter measures the resistance of a material to crack initiation and propagation under a specific loading condition. In the world of nanotechnology, where materials have become smaller and more complex, understanding the fracture toughness of materials has never been more important. Nanoindentation testing is a widely used technique to measure fracture toughness, as it provides insight into the material’s nanostructure and mechanical behavior at sub-micron scales. By applying a specific load onto a nanoscale indenter, one can observe the crack formation and propagation in the material, resulting in valuable information about fracture toughness.

Yield Strength and Fatigue

Yield strength and fatigue are among the key properties that are measured using nanoindentation. Yield strength is the load at which a material begins to deform plastically, while fatigue measures the capacity of materials to resist structural breakdown under repeated loading, leading to progressive damage.

Creep and Relaxation

Creep and relaxation are two important mechanical properties that can be measured during nanoindentation testing. Creep refers to the gradual deformation of a material over time due to a constant load, while relaxation refers to the decrease in stress over time under a constant strain. Both of these properties can be analyzed through nanoindentation testing, allowing researchers to better understand the behavior of materials under different conditions.

Stress and Strain Measurement

Stress and strain measurement are integral to the process of nanoindentation testing process, providing valuable information about the sample’s deformation behavior under an applied load. Stress is the force per unit area experienced by the sample, while strain is the resulting deformation. Together they give insight into the material’s behavior, including stiffness and hardness. In nanoindentation testing, the ability to accurately measure stress and strain is critical to understanding and predicting the material’s response to external forces.

Loss and Storage modulus

Lastly, other two important parameters that can be extracted from nanoindentation testing are the Loss modulus and Storage modulus. The Loss modulus is a measure of the energy dissipated during deformation and is related to the material’s ability to dampen vibrations. The Storage modulus, on the other hand, is a measure of the energy stored during deformation and is related to the material’s stiffness. Together, these properties provide vital information to researchers on the elastic and viscoelastic properties of materials.

By obtaining accurate and precise measurements of described parameters, researchers and engineers can design and optimize materials that meet specific mechanical requirements.

Indenter Types

Nanoindentation testing is a valuable tool for researchers seeking to measure the mechanical properties of extremely small materials. With the use of various types of indenters, researchers can accurately and precisely measure the hardness and other properties of materials. Vickers and Berkovich indenters are often used to measure hardness and elastic modulus on a wide variety of soft and hard materials. Vickers being more resistant at high loads and Berkovich having more sensitivity to thinner coatings. Cube corner can be used at lower forces to measure fracture toughness and conico-spherical indenters are used on soft metals and plastics materials. The conico-spherical indenters also provide a wider contact when measuring materials with high porosity. The Knoop indenter is similar to the Vickers indenter but elongated in shape. This allows to measure directional difference in hardness when materials have fibers for example. Flat indenters are great for crushing small particles or for measuring the ultimate yield strength of a wide range of materials. Special knife diamond can be used to test failure of cylindrical parts such as fiber optics. Each indenter has its own unique properties, and researchers must carefully choose the right one for their specific application to ensure accurate and precise data. Nanoindentation testing is a powerful method that promises to deliver valuable analytical data for research processes, allowing for more precise measurements of the mechanical properties of materials.

Conclusion

In conclusion, nanoindentation is a powerful tool for measuring and analyzing the properties of materials on an atomic scale. It offers many advantages over traditional indentation tests due to its high precision and accuracy. With high number of variables and testing parameters it can be overwhelming to choose the right set for your application in order to ensure accurate results. Fortunately, our knowledgeable NANOVEA representatives can provide guidance on selection of appropriate measurement and analysis techniques, as well as simulate real-world conditions such as high or low temperature, liquids, humidity and vacuum. Take advantage of our live chat now, or use the contact form for a more in-depth consultation. Looking forward to hearing from you soon!