1000°C Brinell Hardness w/ T2000 Tribometer

Material properties, such as reactivity and strength, can drastically change at higher temperatures. This makes high temperature applications, (e.g. jet engines, fabrication chamber material, and even cookware) require careful material selection. Thus, it is important to understand how materials behave in different temperature conditions. The strength of a material can be measured by using the Nanovea T2000 Tribometer. To demonstrate this, a steel sample was used to conduct Brinell hardness testing from temperatures ranging from 25°C to 925°C.

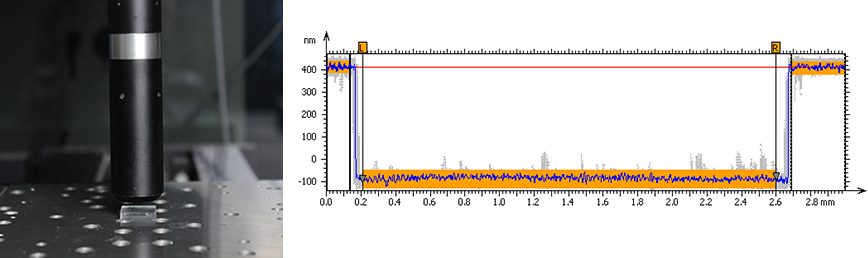

500nm Glass Step Height: Extreme Accuracy with Non-Contact Profilometry

Surface characterization are current topics undergoing intense study. The surfaces of materials are important since they are the regions where physical and chemical interactions between the material and environment occur. Thus, being able to image the surface with high resolution has been desirable, since it allows scientists to visually observe the smallest surface details. Common surface imaging data includes topography, roughness, lateral dimensions, and vertical dimensions. Identifying the load bearing surface, spacing and step height of fabricated microstructures, and defects on the surface are some applications that can be obtained from surface imaging. All surface imaging techniques, however, are not created equal.

500nm Glass Step Height: Extreme Accuracy with Non-Contact Profilometry

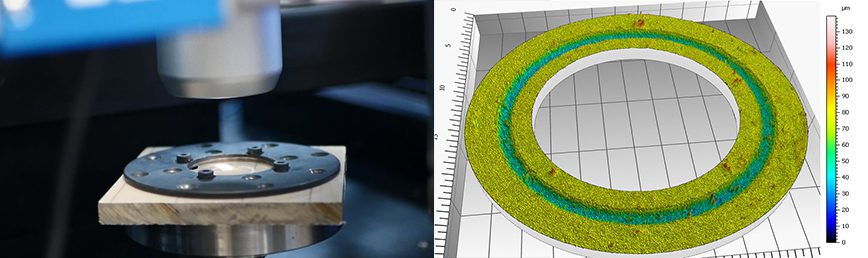

Progressive Tribology Mapping of Flooring

The traffic of human movement, movement of furniture, and other daily activities imposes constant degradation onto flooring. Flooring, usually comprised of wood, ceramic, or stone, must be able to handle the wear and tear they are designed for, whether residential or commercial applications. For this reason, most flooring have a layer that is supposed to be resistant to wear called a wear layer. The thickness and durability of the wear layer will depend on the type of flooring and the amount of foot traffic it will be receiving. Since flooring can have multiple layers (e.g. UV-coating, wear layer, decorative layer, glaze, and etc.), the wear rate through each layer can be very different. With Nanovea T2000 Tribometer with a 3D Non-Contact Line Sensor attachment, the progression of wear on a stone and wood flooring is closely observed.

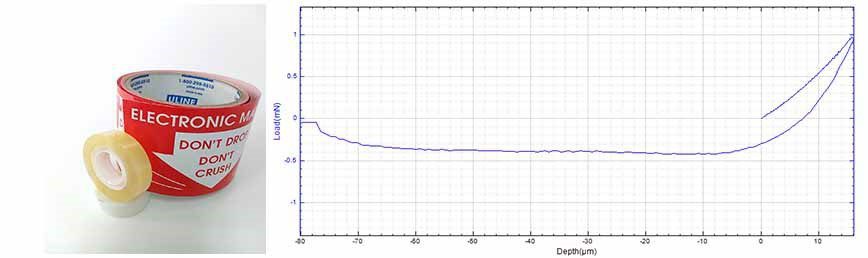

Adhesiveness of Tape via Nanoindentation

The effectiveness of tape is determined by its cohesive and adhesive abilities. Cohesion is defined as the tape’s internal strength while adhesion is the tape’s ability to bond to its interacting surface. The adhesion of tape is influenced by numerous factors, such as exerted pressure, surface energy, molecular forces, and surface texture [1]. To quantify adhesion of tapes, nanoindentation with the Nanovea Mechanical Tester’s Nano Module can be conducted to measure the work required to separate the indenter from the tape.

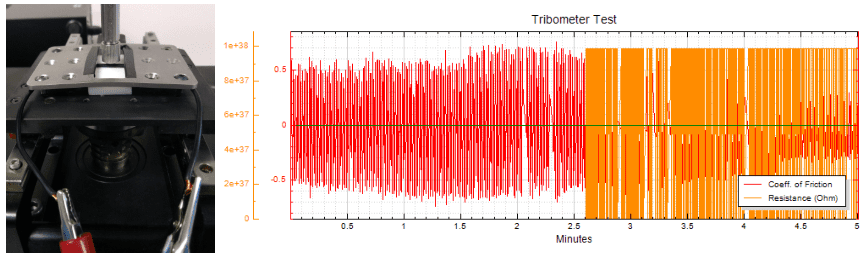

Fatigue Testing of Wire with Electrical Conductance Apparatus

Electrical wires are the most common form of interconnects between electrical devices. Wires are usually made of copper (and sometimes aluminum) due to copper’s ability to conduct electricity very well, ability to bend, and its cheap cost. Outside of material, wires can also be assembled in different ways. Wires can come be obtained in different sizes, usually denoted by gauges. As the wire diameter increases, the wire gauge decreases. Longevity of the wire will change with wire gauge. The difference in longevity can be compared by conducting a reciprocating linear test with the Nanovea Tribometer to simulate fatigue.

Fatigue Testing of Wire with Electrical Conductance Apparatus

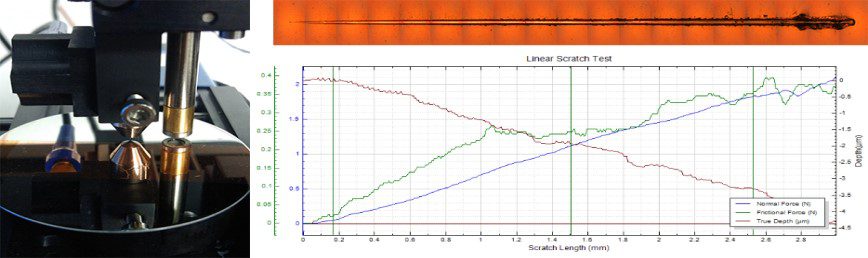

Scratch Testing on Multi-Layered Thin Film

Coatings used extensively throughout multiple industries to preserve the underlying layers, to create electronic devices, or to improve surface properties of materials. Due to their numerous uses coatings are extensively studied, but their mechanical properties can be difficult to understand. Failure of coatings can occur in the micro/nanometer range from surface-atmosphere interaction, cohesive failure, and poor substrate-interface adhesion. A consistent method to test for coating failures is scratch testing. By applying a progressively increasing load, cohesive (e.g. cracking) and adhesive (e.g. delamination) failures of coatings can be quantitatively compared.

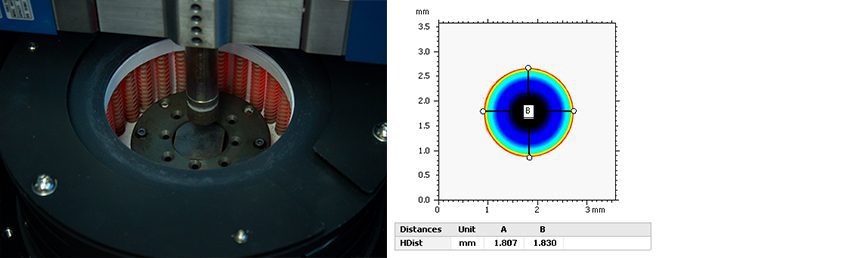

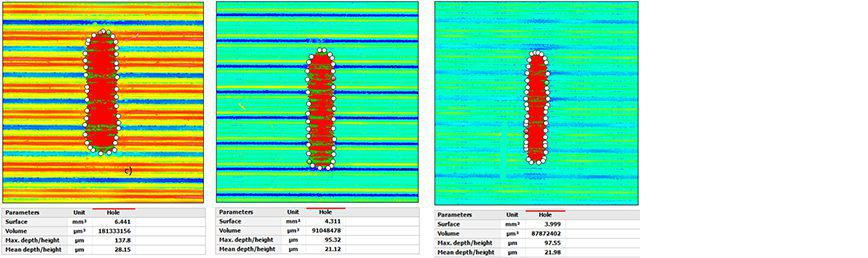

Comparison of Ridge Spacing and Wear Rate on 3D Printed Materials

3D printed material is gaining rise due to its ability to create a large variety of shapes and features without the use of time consuming input. 3D printing does have its limitations, however, such as in the lack of materials that can be used and strength of products. To understand how the quality of 3D printed materials can be improved, the Nanovea Tribometer can be used to conduct wear testing.

Comparison of Ridge Spacing and Wear Rate on 3D Printed Material

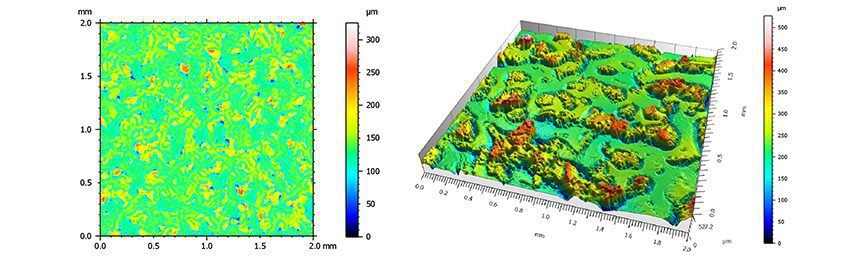

Roughness and Particle Diameter of Sandpaper

Sandpaper is a common commercially available product used as an abrasive. The most common

use for sandpaper is to remove coatings or to polish a surface with its abrasive properties. These

abrasive properties are classified into grits, each related to how smooth or rough of a surface

finish it will give. To achieve desired abrasive properties, manufactures of sandpaper must ensure

that the abrasive particles are of a specific size and have little deviation. To quantify the quality

of sandpaper, Nanovea’s 3D Non-Contact Profilometer can be used to obtain the Sa height

parameter and average particle diameter of a sample area.

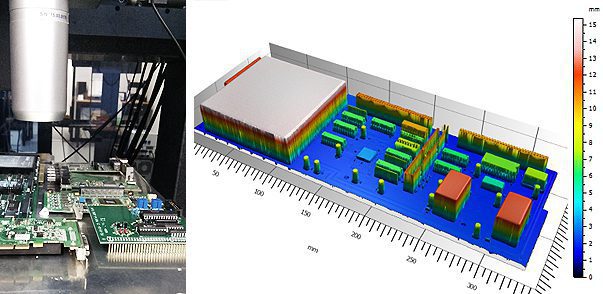

Automated Large Area Profilometry of PCB

Scaling up of manufacturing processes is necessary for industries to grow and keep up with constantly increasing demands. As manufacturing process scales up, the tools used in quality control also need to be scaled up. These tools must be fast to keep up with the production rate, while still maintaining high accuracy to meet product tolerance limits. Here, the Nanovea HS2000 Profilometer, with Line Sensor, showcases its value as a quality control instrument with its fast, automated, and high-resolution large area profilometry capabilities.

Video Clip or App Note: Automated Large Area Profilometry of PCB

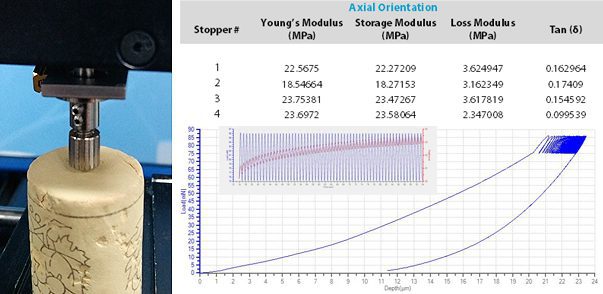

Dynamic Mechanical Analysis With Nanoindentation

The quality of corks depends heavily on its mechanical and physical property. Its ability to seal wine can be identified as these important factors: flexibility, insulation, resilience, and impermeability to gas and liquids. By conducting dynamic mechanical analysis (DMA) testing, its flexibility and resilience properties can be gauged with a quantifiable method. These properties are characterized with Nanovea Mechanical Tester’s Nanoindentaion in the form of Young’s modulus, storage modulus, loss modulus, and tan delta (tan (δ)). Other data that can be gathered from DMA testing are phase shift, hardness, stress, and strain of the material.