Fracture Toughness Measurement Using Nanoindentation

In this study, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to evaluate the fracture toughness of a fused silica sample. The fused silica sample was chosen for its commonly recognized fracture toughness values to display the control and accuracy using nanoindentation.

Wear Resistance of Magnetic Stripes Using Tribometer

In this application, the Nanovea Tribometer is used to simulate the wear process of the magnetic stripes on cards and measure the wear resistance and coefficient of friction in a controlled and repeatable manner.

Dental Screw Dimensions Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure a flat surface along with screw thread features in a single measurement on a dental screw. The surface roughness will be calculated from the flat area, and various dimensions of the thread features will be determined.

2014 Tradeshow Calender

2014 Tradeshow Calender

TMS | February 16-20 San Diego, CA

www.tms.org

NACE CORROSION | March 9-13 San Antonio, TX

www.nace.org

ICMCTF | April 28-May 2 San Diego, CA

www.avs.org

CONTROL | May 6-9 Stuttgart Germany

www.control-messe.de

IMTS | September 8-13 Chicago, IL

www.imts.com

MS&T | October 12-16 Pittsburgh, PA

www.matscitech.org

Here are examples of materials we tested this month:

Mechanical:

• High Temp Nanoindentation of ptfe coatings

• Nanoindentation of Al2O2 coating on silicon substrate

• Nano scratch of sapphire coatings

• Nanoindentation yield strength of pipe samples

3D Non-Contact Profilometry:

• Topography of porous polymer foam structure

• Topography of steel fracture sample

• Roughness of pharmaceutical tablets

• Volume & Depth of pcb holes

• Coplanarity of micro features

Tribology:

• Wear testing of simulated silicate rock samples

• Wear testing of dlc coatings

• Wear Testing spray coatings

• Wear & Friction Testing lubricated composite samples

VISIT NANOVEA AT MMC 2014

Visit with Nanovea’s exclusive distributor, Mi-Net, at MMC 2014 booth 312. MMC 2014 is the combination of the very best of the 2012 European Microscopy Congress and the MICROSCIENCE International Conference and Exhibition series, by the Royal Microscopical Society. Contact Mi-Net to learn more.

Rotative and Linear Wear Comparative Study

The wear rate of an acrylic plate is measured in a controlled and monitored manner using linear and rotative wear test setups on the Nanovea Tribometer for comparison. In this study we would like to showcase the versatility of the Nanovea Tribometer in measuring wear rate using multiple setups.

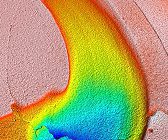

Tooth Wear Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the surface of a tooth sample mounted in epoxy that has been put through a chewing simulator. The area measured was the resulting wear and the surrounding surface area. The

maximum width, depth, perimeter, surface area, and volume lost will be used to characterize the wear track.

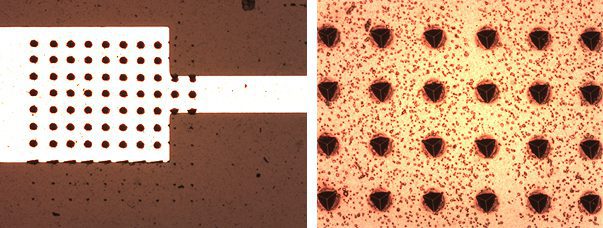

FastMap High Speed Nanoindentation Mapping

With speed as fast as 3 seconds per indent using a fast piezo controller, Nanoindentation mapping can now be achieved with reproducibility and accuracy only seen at lower speeds until now.

Surface Measurement. What Interferometry Is Not Telling You.

What’s important ACCURACY or RESOLUTION? Nanovea gathers critical information on the matter and further evaluates Interferometry versus Axial Chromatism. Although resolution provides a nice image on the screen, is it accurate? Learn more