Monthly Archives: August 2017

Micro Scrape Test Of Polymeric Coating

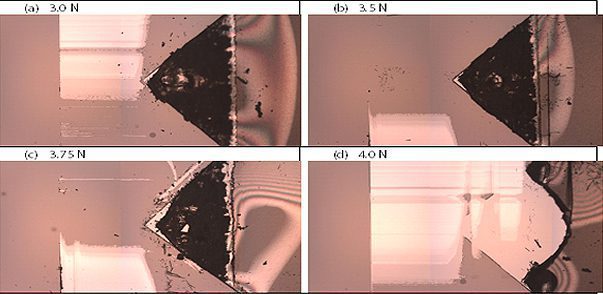

Scratch testing has developed to be one of the most widely applied methods to evaluate the cohesive and adhesive strength of the coatings. The critical load, at which a certain type of coating failure occurs as the applied load progressively increases, is widely regarded as a reliable tool to determine and compare the adhesive and cohesive properties of the coatings. The most commonly used indenter for scratch testing is the conical Rockwell diamond indenter. However, when the scratch test is performed on the soft polymeric coating deposited on a brittle substrate such as silicon wafer, the conical indenter tends to plough through the coating forming grooves rather than creating cracks or delamination. Cracking of the brittle silicon wafer takes place when the load further increases. Therefore, it is vital to develop a new technique to evaluate the cohesion or adhesion properties of soft coatings on a brittle substrate.