Monthly Archives: August 2015

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation & scratch of tungsten carbide coatings

• Nanoindentation DMA of fluoropolymer

• Microindentation & scratch of DLC coatings

• Macro scratch firearm parts

3D Non-Contact Profilometry:

• Roughness of precision machined components

• Texture of textile samples

• Coplanarity of ball grid arrays

• Volume loss of dental samples

• Flatness measurement of micro seals

Tribology:

• Wear resistance of hard polymers

• Wear resistance of firearm parts

• High temperature fretting of engine parts

• Stribeck Curve of lubricants

3D Topography With Image Overlay of PCB

The more sophisticated electronic design and layout of semiconductor chips, circuits and systems requires high precision manufacturing and superior quality control. Unlike other techniques such as touch probes or interferometry, the Nanovea 3D Non-Contact Profilometer, using axial chromatism, can measure nearly any material surface. Nano through macro range is obtained during surface profile measurement with zero influence from sample reflectivity, absorption and high surface angles. This is ideal for surface inspection of the PCB assembly (PCBA), which contains a variety of electronic components of different materials, reflectivity and fine features. Moreover, the non-contact profiling technique measures the surface features without touching the PCBA, avoiding the risk of damaging the delicate circuits and electronic components due to sliding of the probe stylus. The combination of high precision, high speed, non-contact and user friendliness makes the Nanovea Profilometer an ideal tool for PCBA inspection.

Copper Wire Coating Failure Using Tribology

The surface quality of copper wire is critical in its service performance and lifetime. The micro defects in the wire surface may lead to excessive wear, crack initiation and propagation, and inadequate solderability. Proper surface treatment can remove surface defects that are generated during wire drawing, and improve the corrosion, wear and scratch resistance of the copper wire. Many applications such as aerospace and commercial airliner require copper wires to behave in a controlled manner to prevent unexpected equipment failure. Quantifiable and reliable measurements are in need in order to quantitatively evaluate the wear and scratch resistance of the copper wire surface.

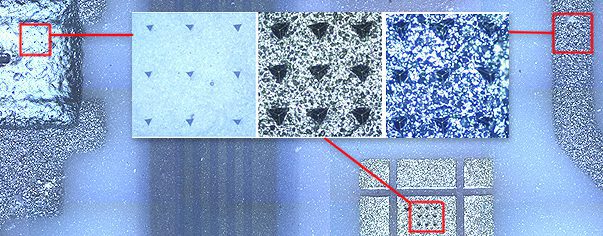

Mechanical Property Broadview Mapping Tool

Seen above is an example of Nanovea’s patent pending Broadview Map Selection Tool. This new tool allows users easy selection of any location on a broad stitched surface view of the sample. Additionally, the user can select all testing parameters at each location, either for a one test or a multi-tests mapping. All locations and test parameters can be saved in easily retrievable recipes. This significant advancement provides fast & friendly Nano through Macro mechanical property studies. Learn more in this months app note: Mechanical Property Mapping