Monthly Archives: February 2014

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of antireflective coatings

• Nanoindentation of biomedical gels

• Nanoscratch of fused silica and silicon

• Nanofriction of micro rubber stoppers

• Microscratch of anodized titanium

3D Non-Contact Profilometry:

• Roughness of thermal coatings

• Finish of hip implant

• Flatness & Planarity of electrical contacts

• Shape and Form of stamped sheet metal patterns

• Dimensions of molded plastic lenses

Tribology:

• Wear testing of tool steel grip pads

• High temperature wear testing of ceramics

VISIT NANOVEA AT CORROSION 2014 NEXT MONTH!

San Antonio | CORROSION ( Mar 9-13 ) Visit the Nanovea booth to learn more about this months application notes below. To be held at the Henry B. Gonzalez Convention Center in San Antonio, Texas. Learn more

Tribocorrosion Wear Evaluation of Protective Coating

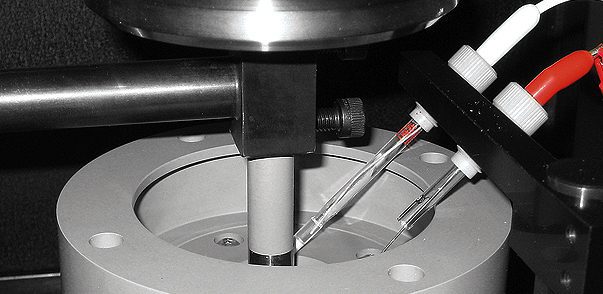

The tribocorrosion process of the DLC coatings on different types of steel substrates is simulated using the Nanovea Tribometer. In this study, we would like to showcase that Nanovea Tribometer equipped with the Tribocorrosion Module is an ideal tool for evaluating the performance of protective coatings used in wear and corrosion environment.

Pitting Corrosion density, area, volume, size and shape

In this application the Nanovea ST400 Profilometer is used to measure the surface of a corrosion pitted stainless steel coupon. The area measured was selected at random, and assumed large enough in that it could be extrapolated to make assumptions

about a much larger surface. Density, area, volume, size and shape will be used here to quantify the level of corrosion.